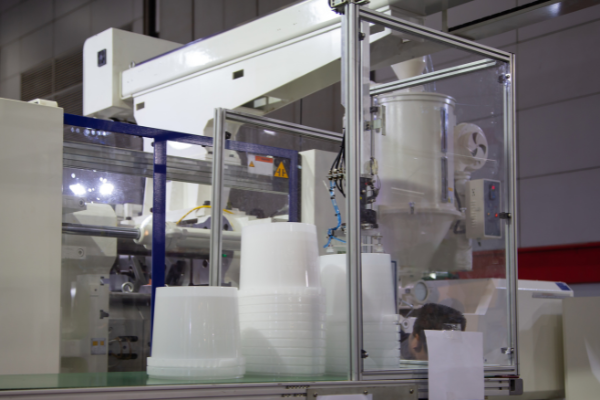

The injection molding process is one of the plastic parts’ most popular manufacturing methods. It involves injecting raw material into a mold. That material is cooled, solidified, and ejected from the mold as a finished product.

Injection molding has produced thousands of items, from small toys to large industrial equipment. It can create parts made from various materials, including polypropylene, polycarbonate, and ABS (acrylonitrile butadiene styrene).

Here are 12 injection molding materials that are commonly used in this manufacturing process:

Polypropylene (PP)

Polypropylene (PP) is a thermoplastic polymer and one of the most widely used materials in the world. It is cheap, strong, durable, and resistant to chemicals, heat, and abrasion. This makes it ideal for injection molding parts used in harsh environments.

Polypropylene is a very easy material to work with and can be injection molded into almost any shape using conventional techniques. It can also be blow molded into bottles or tubes through rotational molding. This process allows PP to be formed into complex shapes that are impossible to make using traditional techniques like injection molding.

Polystyrene (PS)

Polystyrene (PS) is the most common thermoplastic used for injection molding. It is also known as styrene, the monomer used to make PS. PS has a high tensile strength and good impact strength, making it ideal for applications such as toys and other consumer products.

Because of its low cost, PS is often used to produce large-scale products such as automotive parts and appliances. In addition, PS can be easily colored using dyes or pigments, allowing manufacturers to create a wide range of colors and finishes without adding much cost to the product.

PS can be easily machined with traditional milling machines to create intricate parts that are difficult to mold using other materials. It also has good electrical conductivity and can be easily printed onto UV inkjet printers or screen printing machines.

Nylon

Nylon has many advantages over other materials. It is a very strong material and can be molded into complex shapes with high precision. It is also relatively inexpensive and resistant to corrosion and abrasion. The main downside of nylon is that it tends to have a yellowish cast, making it difficult to match with other plastics or metals.

Nylon has been used in injection molding since the 1950s when DuPont introduced it as an alternative to bakelite, which had previously been used for decades in this application.

Nylon has several advantages over other materials, making it a good choice for injection molding. It is a very strong material and can be molded into complex shapes with high precision. It is also relatively inexpensive and resistant to corrosion and abrasion, making it ideal for many industrial applications (such as medical devices). In addition, nylon does not require special handling techniques during production or use; unlike other plastics, you can cut or drill nylon without worrying about releasing toxic fumes or dealing with dangerously sharp edges afterward.

One significant downside of nylon is its tendency toward yellowing over time; this color change may occur even if the material remains untouched by sunlight. This discoloration makes nylon unsuitable for certain applications, such as food packaging or photo printing.

ABS (Acrylonitrile Butadiene Styrene)

Short for acrylonitrile butadiene styrene, ABS is a thermoplastic polymer manufactured in injection molded parts. Although not as strong as engineering plastics such as nylon or polypropylene, ABS can be molded into complex shapes with good detail and has high impact strength.

ABS is a common material for hobbyists and small businesses that need to make large quantities of custom parts. It’s also commonly used in consumer products like toys, pipes, and automotive parts.

PETG (Polyethylene terephthalate glycol-modified)

PETG is a modified form of PET. It has a higher heat resistance than PET and can be exposed to temperatures up to 100°C (212°F) without breaking down. This makes it an ideal material for producing food packaging, medical devices, and industrial components such as pipes, valves, and fittings.

The chemical composition of PETG allows it to be processed at higher temperatures than PET. However, there are still some limitations to its use: while PETG is suitable for most injection molding machines, it cannot be processed in lower-cost machines with only one material.

PC/ABS Blends

PC/ABS blends are one of the most common types of injection molded plastic. These materials are ideal for many applications and can be used for many products.

PC/ABS blends are usually made up of polycarbonate and ABS plastic. These two materials have very different properties, but they combine to create a material with a high strength-to-weight ratio.

The polycarbonate component contributes impact resistance and rigidity to the blend, while the ABS component provides toughness, toughness, and impact resistance. The resulting plastic is strong yet lightweight, making it ideal for many applications.

The main advantage of PC/ABS blends is their high strength-to-weight ratio. This means they’re stronger than other plastics but also lighter in weight than other plastics. If you need something that will hold up well under stress but won’t weigh your product down, PC/ABS blends may be an excellent choice for you!

PBT (Polybutylene terephthalate)

PBT is a semi-crystalline thermoplastic used in injection molding, extrusion, and thermoforming. PBT has high mechanical strength and good rigidity. It is used for automotive parts and electrical products because of its heat resistance properties. PBT has good chemical resistance to many solvents and oils, making it suitable for applications involving petroleum products or other chemicals.

PBT is used in various applications, including automotive parts, electrical components, and appliances.

PCTFE (Polychlorotrifluoroethylene)

Polychlorotrifluoroethylene (PCTFE) is a fluoropolymer that is used in injection molding. It has high heat resistance, good chemical resistance, and low friction characteristics.

PCTFE has good mechanical properties but poor impact strength and low tear strength, making it suitable for plastic parts such as medical equipment, car parts, and electronics.

PCTFE can be processed by injection molding or compression molding. It is also used in extrusion coating applications because of its ability to withstand high temperatures.

PVC (Polyvinyl Chloride)

PVC is a common injection molding material. It is used in the pharmaceutical industry to make syringes and other medical devices. PVC is also used to make water pipes, toys, garden hoses, and many other products. It has a low cost and good strength properties for its weight.

PVC can be molded using almost any process that can be used with polystyrene (PS) or acrylonitrile butadiene styrene (ABS). The only problem with PVC is that it has a fairly high coefficient of thermal expansion (CTE). When it cools from the molding temperature, it shrinks slightly. This can cause problems with parts that have tight tolerances or are under stress because they will expand when cooled more than expected and be too big for their intended use.

PVAc (Polyvinyl Acetate)

PVAc is a polyvinyl acetate used as a binder in injection molding applications. PVAc is commonly used in the plastic industry because it is inexpensive, easy to work with, and has good flow characteristics. PVAc has been used to manufacture molded parts for over 20 years. PVAc is typically used for short cycles and low to medium-volume production runs.

PVAc has a low viscosity at room temperature so that it will flow easily into the injection mold cavity during the heating phase. However, as the material heats up during the injection phase, it becomes more viscous and begins to gel or set up within the mold cavity. This characteristic allows PVAc materials to be used for short cycle times (as short as 25 seconds) with minimal cooling time between shots.

PVDF

PVDF is a fluoropolymer most often used in injection molding as an alternative to PTFE. PVDF has better chemical resistance than PTFE, making it suitable for applications that require exposure to aggressive chemicals or high temperatures. PVDF also has a higher melting point than PTFE, which allows it to withstand higher injection pressures.

The mechanical properties of PVDF are similar to those of PTFE: both materials have low coefficients of friction, high tensile strength and elongation at break, and excellent dimensional stability. They also have good electrical insulation properties.

PEEK (Polyetheretherketone)

PEEK is a very strong, stiff, and high-temperature-resistant material. It has good chemical resistance to most chemicals, but strong acids and bases can attack it.

It has a high degree of dimensional stability and can be used over a wide temperature range (-60 to +250°C). Because of its excellent mechanical properties, PEEK is well suited for applications requiring a low coefficient of friction, good wear resistance, and shock resistance.

PEEK is commonly used in applications requiring high-temperature resistance where the metal cannot be used because of corrosion concerns. This includes automotive fuel lines, header pipes, head gaskets, and oil pans.

How to Choose the Right Material for Your Injection Molding Project

The type of material you choose for your injection molds will depend on your project and the desired end product. There are several factors to consider when choosing the right material for your injection molding project:

When selecting the right material for your injection molding project, there are many factors to consider. Here are a few things to think about when choosing plastic.

Strength

The amount of stress your part will be subjected to will determine how strong the material needs to be. For example, if you’re making a part used in an automotive application, it must withstand high temperatures and environmental stressors like oil and grease. However, if you’re making a part for consumer use, you may need a more sturdy plastic.

Durability

Durability is another factor determining what type of plastic you should use for your project. For example, if you’re making a part that will be handled frequently or used in harsh environments (e.g., automotive), then it makes sense to choose a more durable plastic like ABS or PC. You can also choose different colors and finishes to make the product more appealing and durable! However, if you’re making a part for consumer use, it may be less durable. You can choose a different type of plastic that might be more lightweight or flexible than ABS or PC.

Cost

The last thing you want is to spend money on materials that are too expensive or not worth the investment. Many plastics are available on the market today, and they all have different properties. Some are more durable than others; some are lighter, and some cost more. However, if you’re making a part for consumer use, it may be less durable. You can choose a different type of plastic that might be more lightweight or flexible than ABS or PC. Cost: The last thing you want is to spend money on materials that are too expensive or not worth the investment.

Conclusion

You now have some key information to help you select the best injection molding materials. However, don’t simply consider this list. All these materials each have their unique set of characteristics that you’ll need to consider to make the right decision.