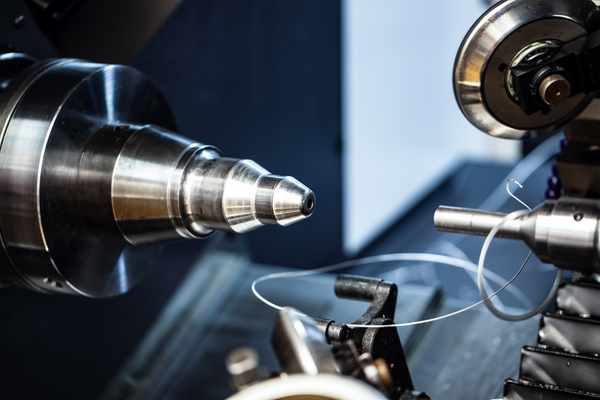

Improving thin-walled parts made by CNC Turning

Turning a small diameter hole inside a thin-walled part is best done with a spiral toolpath rather than a conventional straight axis toolpath. Spiral toolpaths use tighter paths to perform the cutting, causing less stress and chatter on the tool and allowing higher feed rates, resulting in a better finish. Additionally, the chip can be “caught” by the cutter’s rake face more effectively, meaning clogging is less likely. The result of all this is an improved surface finish and less tool wear.