What do you need the machine for

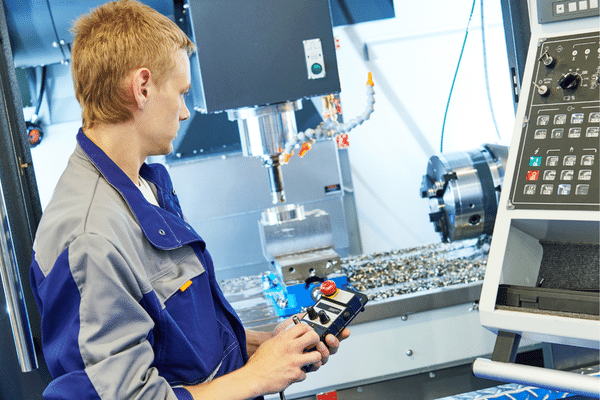

If you are looking for a machine to help you with your Cnc Parts China, there are many options available. You can choose from manual machines, semi-automatic machines or fully automatic machines. The choice will depend on your budget, the amount of work you need to do and whether you want to buy a new or used machine.

Manual machines are often cheaper than other types of machine, but they require more skill and effort from the user. They are usually not as efficient as other types of machine because they require more effort from the operator and they tend to have fewer features than other types of machine.

Semi-automatic machines allow users to perform some operations without having to rely on another person or another piece of equipment, but they still require some manual labour on behalf of the user. Semi-automatic machines are often used in small businesses or by hobbyists who want to save money while getting good results at home rather than purchasing expensive equipment that they might not use regularly enough to justify its cost.

Fully automatic machines allow users to perform all operations without having any input from another person or piece of equipment except for periodic maintenance checks and cleaning procedures that must be completed by hand due to their complexity (such as changing out parts when necessary). A semi-automatic machine is more affordable than a fully automatic one, but it still requires some manual labour on behalf of the user. Semi-automatic machines are often used in small businesses or by hobbyists who want to save money while getting good results at home rather than purchasing expensive equipment that they might not use regularly enough to justify its cost. Fully automatic machines allow users to perform all operations without having any input from another person or piece of equipment except for periodic maintenance checks and cleaning procedures that must be completed by hand due to their complexity (such as changing out parts when necessary).

Semi-automatic machines are often used in small businesses or by hobbyists who want to save money while getting good results at home rather than purchasing expensive equipment that they might not use regularly enough to justify its cost. Fully automatic machines allow users to perform all operations without having any input from another person or piece of equipment except for periodic maintenance checks and cleaning procedures that must be completed by hand due to their complexity (such as changing out parts when necessary).

What type of materials will be machined

What type of materials will be machined?

Cnc Parts China are made from a variety of materials, including steel, aluminum, plastic and wood. Cnc Parts China can be machined to fit any size or shape needed. The most common type of material used to manufacture Cnc Parts China is steel. Steel is often used in the manufacturing process because it is strong and durable, which allows for long-lasting use. However, some Cnc Parts China are made from aluminum or plastic instead of steel. This can be beneficial because it allows for lighter weight products that are easier to transport and install.

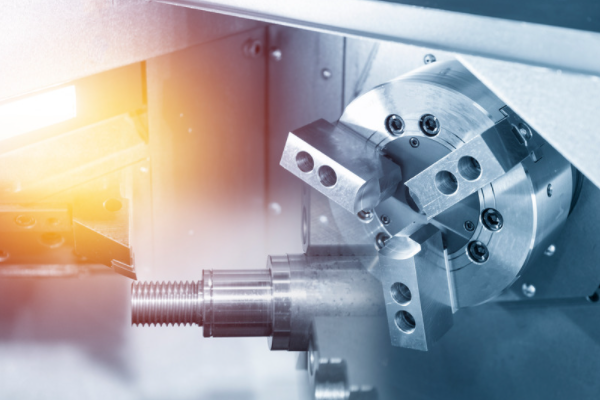

The most common types of Cnc Parts China include drills, lathes and milling machines. Drills are used to drill holes into metal or wood surfaces; this is usually done at high speeds so that the drill can cut through these materials easily without breaking apart or bending out of shape during operation (see image below). Lathes are used for shaping metal pieces into specific shapes such as cylinders or cones; these machines use circular movements around an axis point in order to spin outwards from that point like spokes on a wheel (see image below). Milling machines work similarly but instead use sliding motions between two wheels in order to cut out a specific shape from a piece of metal. These three machines are all used for manufacturing purposes, and the different types of drills can be used for both industrial and consumer applications.

There are two types of drills: hand-held and stationary. Hand-held drills can be used for smaller jobs, such as drilling holes into wood or metal; they are usually powered by electricity or compressed air. Stationary drills are much larger than hand-held drills,

The size of parts to be machined

The parts to be machined are all made of steel. The length and width of the parts vary, but they are basically square and rectangular shapes. The thickness ranges from 2 mm to 25 mm.

The machines used for this operation are CNC lathes, milling machines, and drill presses. All of these machines have a similar structure, with a rotating spindle that is powered by a motor or engine. The different types of machines operate in different ways but share the same basic function: cutting or shaping metal using tools called cutters or milling cutters.

When a part is placed on the machine’s bed or table and then clamped down with clamps or fixtures so it does not move during the cutting process, it is known as “holding down.” This step ensures that the part remains steady during machining operations so that it does not become damaged or distorted from excessive vibration during machining operations due to poor clamping practices used by inexperienced operators who lack fundamental knowledge about how proper clamping practices should be followed when working with different types of materials (e.g., metals) being processed using various types of machinery (e.g., lathes). Holding down is also known as “clamping.”

The most common type of clamping is done by hand. Hand clamps are usually made from wood or plastic, and they have a padded surface that holds the material being cut firmly in place while it is being machined.

Another type of clamping is done with clamps that are operated by a lever or screw. The most common types of clamping devices are vices, vises and clamps. Vices are used for holding cylindrical work pieces, while vises can be used for holding any type of material in place while it is being worked on.

The accuracy and tolerances required

The accuracy and tolerances required for Cnc Parts China are as follows:

1. Accuracy: The accuracy required for a Cnc Parts China is 0.0005mm

2. Tolerance: The tolerance required for a Cnc Parts China is 0.005mm -0.01mm

3. Surface Finish: Surface finish refers to the smoothness of the surface of a part, which can be any type of finish from rough to smooth, depending on what is needed for the application. Depending on what you are doing with your part, you may need it to have a high degree of surface finish or just enough to make sure that it isn’t too rough and uncomfortable to touch or use with bare hands in case you are going to put it inside something like a computer case where people will be touching it frequently without wearing gloves or other protective gear (for example). In this case we would recommend using a fine grit sandpaper with lots of pressure applied evenly across each side until all nicks are gone then wipe off excess dust with an old rag or paper towel before moving onto next step; if there were any imperfections left over from previous steps then repeat until all imperfections are gone and finished product looks smooth and uniform.

This step is optional but highly recommended; you can wash your finished product with a mild detergent and warm water using a soft bristle brush if there are any fingerprints or smudges left over from previous steps. This will make it look much nicer and more professional for use in public places such as schools, libraries and hospitals.

The number of parts to be produced each day/week/month

The number of parts to be produced each day/week/month is a very important parameter. This is because it determines how many products can be made in a given period of time and also how much profit can be earned from the products. The higher the number of parts produced by Cnc Parts China every day/week/month, the greater the productivity will be and the more money you will make.

The size of each part will also determine how many parts can be produced per day/week/month. If one part takes up too much time or costs too much money to produce, then it will take longer than expected to make all of them or cost more than expected, which means that fewer parts can be made in less time and less money will be made overall.

When looking at your current production capacity and comparing it with your actual production capabilities, you should consider other factors such as: quality control, delivery times, packaging costs etc., as well as what kind of tools are being used (if any).

If there’s anything else we can do for you today please let us know! If you need to increase your production capacity, then you’ll need to purchase more resources (such as land and machinery) or hire more people. This will take time, but it’s an important step if you want to expand your business. You should also consider the kind of quality control measures that are in place for each part of production; if one part takes up too much time or costs too much money to produce, then it will take longer than expected to make all of them or cost more than expected, which means that fewer parts can be made in less time and less money will be made overall.

If you want to make more money, then you’ll need to increase your production capacity. This means purchasing more resources or hiring more people. You should also consider the quality control measures that are in place for each part of production; if one part takes up too much time or costs too much money to produce, then it will take longer than expected to make all of them and cost more than expected, which means

Whether or not CAD drawings are available

Step 1: The first step is to open the CAD file.

Step 2: The second step is to make sure your Cnc Parts China software is up-to-date.

Step 3: The third step is to check the dimensions of your Cnc Parts China parts, and make sure they’re correct.

Step 4: The fourth step is to check your Cnc Parts China part’s tolerances, ensuring that they meet industry standards.

Step 5: The fifth step is to verify that all of the holes are square, parallel, and concentric with their respective axes. If not, you’ll need to drill them out and re-drill them with a new bit at a lower RPM setting so they don’t burn out as quickly or warp during use.

Step 6: The sixth step is to verify that all of the holes are round enough for whatever purpose they were designed for (i.e., if it’s meant for bolting together two pieces without using glue or another adhesive). If not, you’ll need an appropriate tool (such as a file) in order to shape them into their final form before drilling begins again from scratch; otherwise, you may end up with a product that doesn’t function properly when assembled together from multiple pieces. Step 7: The seventh step is to make sure that all of the holes are aligned properly, meaning they’re in a straight line and not crooked or wobbly (which would cause problems with assembly). If they’re not aligned properly, use something like a ruler or level to ensure that they are; otherwise, you’ll end up with a product that doesn’t function properly once it’s all put together.

Step 8: The eighth step is to drill all of the holes into the product so that everything fits together properly. This is a crucial step, and if you don’t do it right, then your product will not function properly once assembled (or even just sitting on your desk).