Aluminum milling is a process of removing metal from a workpiece using rotary cutters. It is also known as machining. It is one of the most common operations in manufacturing. The process can be done on several different materials, but aluminum is one of the most popular metals to mill.

Aluminum milling services can be used for a wide variety of applications. Some of the most common include creating prototypes, fabricating parts, and producing molds. The benefits of aluminum milling are vast. It is a versatile process that can create complex shapes and geometries. It is also relatively fast and cost-effective. In this blog post, we will discuss this.

How Does Aluminum Milling Work?

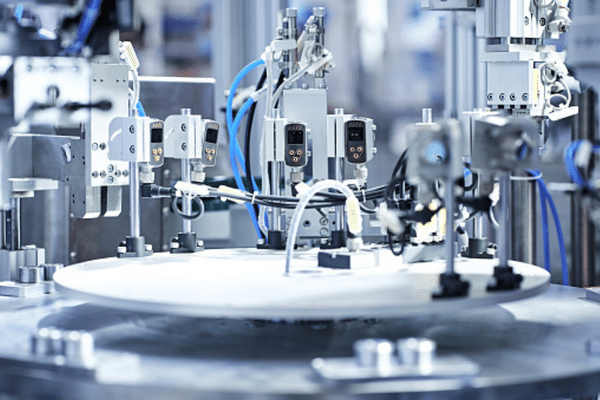

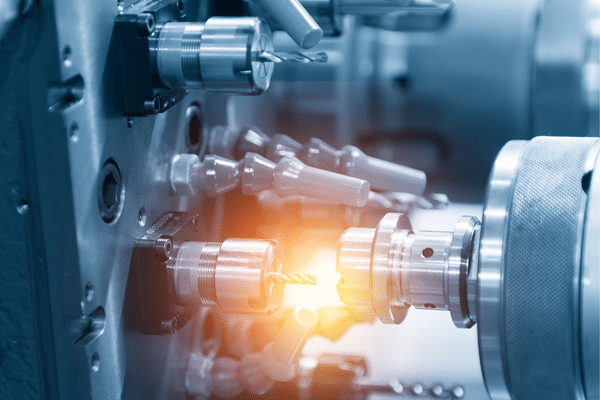

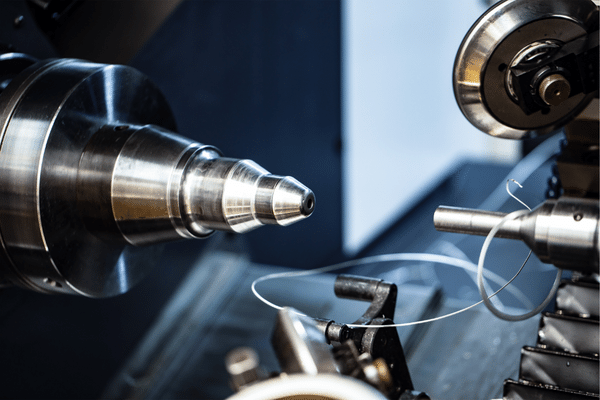

The aluminum milling process begins with a block of aluminum that is placed on a rotary table. The table is then lowered so the cutting tools can contact the aluminum. The cutting tools are mounted on a spindle that rotates at high speeds. As the cutting tools come into contact with the aluminum, they remove small metal chips.

The cuts’ speed, depth, and direction are all controlled by computer numerical control (CNC) software. This software allows for precision machining and repeatability. CNC machines also have coolant systems that keep the tools and workpieces cool during the machining process.

What Are The Benefits Of Aluminum Milling?

There are many benefits to using aluminum milling services, some of which include the following:

- Versatility: Aluminum milling services can create complex shapes and geometries.

- Speed: The process is relatively fast and can be completed in a matter of days or weeks, depending on the complexity of the part being milled.

- Cost-effectiveness: Aluminum is affordable, and milling is often more cost-effective than other fabrication methods such as welding or casting.

- Repeatability: CNC machines allow for repeatable machining processes, which means parts can be reproduced quickly and easily.

How to Know if Aluminum Milling Service is Right for Your Project

How to Know if Aluminum Milling Service is Right for Your Project

When looking for a metalworking partner, it’s important to research and ask the right questions. After all, not every shop is created equal. In this blog post, we’ll help you understand what sets aluminum milling services apart so you can make an informed decision about whether or not this is the right solution for your project.

These are just a few reasons why aluminum milling has become a popular choice for manufacturing parts and components. If you’re still on the fence about whether or not this is the right solution for your project, we’ve outlined a few key considerations to help you make a decision.

Key Considerations for Choosing Aluminum Milling Services

- What are your project requirements?

- What is your budget?

- What is the lead time?

- What are the tolerances?

- What is the surface finish?

Once you have answers to these questions, you can narrow your search for the perfect aluminum milling partner. At Metric Marketing, we offer high-quality milling services that meet even the most stringent requirements. We also offer competitive pricing and quick turnaround times so you can get your project off the ground as soon as possible. Contact us today to learn more about our capabilities or request a quote for your next project!

When choosing an aluminum milling service, there are many factors to consider. In this blog post, we’ve outlined some key considerations to help you decide whether or not this is the right solution for your project. If you have any further questions or want a quote, don’t hesitate to contact us today!

How Much Does Aluminum Milling Service Cost?

When you need aluminum milling services, one of the first questions you’ll likely ask is, “How much does this service cost?” The answer to that question isn’t always as simple as it seems, as many factors can impact the cost of aluminum milling services. Let’s take a look at some of those key factors so you can better understand what goes into the price of this type of service.

Type of Milling Machine Used

One of the biggest factors that will impact the cost of your aluminum milling service is the type of milling machine used. Three main types of milling machines are commonly used for aluminum milling: bed mills, turret mills, and CNC (computer numerical control) mills. Bed mills are the most basic type of milling machine and, thus, tend to be the most affordable option. Turret mills are more advanced than bed mills and can handle more complex projects, which generally results in a higher price tag. CNC mills are the most advanced type of milling machine and can handle even the most complex projects; however, they also come with the highest price tag.

The Size and Complexity of Your Project

Another factor that will impact the cost of your aluminum milling service is the size and complexity of your project. A larger and more complex project will take more time and effort to complete than a smaller and simpler one, which means it will also generally cost more. If you have a large or complex project, be prepared to pay more for your aluminum milling service.

The Number of Pieces You Need Milled

If you only need one milled, that will cost less than 10 pieces. The number of pieces you need to be milled will directly impact how much you’ll pay for your aluminum milling service.

As you can see, several different factors can impact the cost of your aluminum milling service. The type of machine used, the size and complexity of your project, and the number of pieces needed all play a role in determining the price. When shopping around for quotes from different companies, keep these factors in mind to choose the best option for your needs and budget.

How long does aluminum milling take?

When you order a custom aluminum product, you probably want to know how long it will take to receive your finished product. The answer to this question depends on a few factors, including the product’s size and complexity, the materials’ availability, and the shop’s current workload. In this blog post, we’ll break down each of these factors so you can better understand how long your aluminum milling project might take.

The size and complexity of the product is perhaps the biggest factor in determining how long it will take to receive your finished product. A small, simple part can be milled fairly quickly, while a large, complex part can take much longer. Generally, it’s safe to assume that a larger and more complex part will take longer to mill than a smaller and simpler one.

The availability of materials is also an important factor. If we need to order special materials for your project, that will add some time to the overall timeline. However, we can start working on your project immediately if we have all the materials.

Finally, the current workload of the shop is also a consideration. We might have a lot of projects ahead of yours in line, or we might have some downtime between projects. It will take longer to get to yours if we’re already busy with other projects. However, if we have some free time in the shop, we might be able to work on your project more quickly.

In conclusion, a few factors determine how long it will take to receive your finished aluminum product. The size and complexity of the product is perhaps the most important factor, but the availability of materials and the current workload of the shop are also considerations. We hope this blog post has given you a better understanding of how long your aluminum milling project might take. Thanks for reading!

Guidelines for Custom Milling Services

Here at aluminum milling services, we specialize in custom-milled products. This means we can create products of any size or shape that our clients need. Whether you need a small part for a prototype or a large piece for mass production, we can help. In this blog post, we’ll outline some of our custom milling services guidelines so that you know what to expect.

Size and Shape Restrictions

There are no restrictions on the size or shape of the product you can make. We have state-of-the-art equipment that can handle any size or shape you need. The only thing to remember is that the larger and more complex the product, the longer it will take to produce.

Material Restrictions

We specialize in milling aluminum but can also accommodate other materials upon request. We have a wide range of experience with different materials, so feel free to ask us about your specific needs. We generally prefer to work with softer metals like aluminum because they’re easier to mill. Harder metals like steel can be milled, but it requires special equipment and techniques that add to the cost and production time.

Quantity Restrictions

There are no restrictions on quantity either. Whether you need one or one million pieces, we can produce them for you. Remember that the more pieces you need, the longer it will take to produce them. We recommend ordering in batches so that we can work on multiple projects at once and get your products to you as quickly as possible.

We hope this overview of our custom milling services has been helpful. If you have any further questions or want to place an order, please don’t hesitate to contact us. We look forward to working with you!

Custom Milling Services

We provide our clients with high-quality custom aluminum products at an aluminum milling service. We offer various services, such as CNC machining, anodizing, and powder coating. We also offer a custom design service so that you can get the exact product that you need.

Custom Design Service

Our team of experts can help you design the perfect product for your needs. We consider the product’s function, the environment it will be used, and its aesthetics. We then create a 3D model of the product so that you can see what it will look like before we start production. This ensures that you are getting exactly what you want.

We understand that not everyone is an expert in design, which is why we offer this service. We want to make sure that you are happy with the result. Contact us today to learn more about our custom design service.

CNC Machining

We use state-of-the-art CNC machines to create precision products. This means that your products will be made to exact specifications. CNC machining is perfect for products that need to be very precise, such as medical equipment or aerospace parts.

Anodizing

Anodizing is a process where we coat aluminum with a protective layer. This layer protects aluminum from corrosion and makes it more durable. Anodizing also gives aluminum a unique color or finish. This is a great option if you want your products to have a unique look.

Powder Coating

Powder coating is another option for giving your products a unique look. Powder coating is a type of paint that is applied using an electrostatic process. This creates a smooth, even finish that is very durable. Powder coating is available in a wide range of colors, so you can make your products stand out from the crowd.

At aluminum milling service, we offer high-quality custom aluminum products. We have a variety of services, such as CNC machining, anodizing, and powder coating. We also offer a custom design service to get exactly what you need. Contact us today to learn more about our services and how we can help you create the perfect product for your needs.