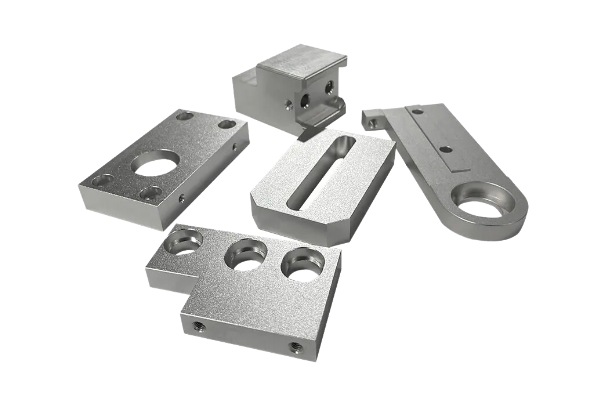

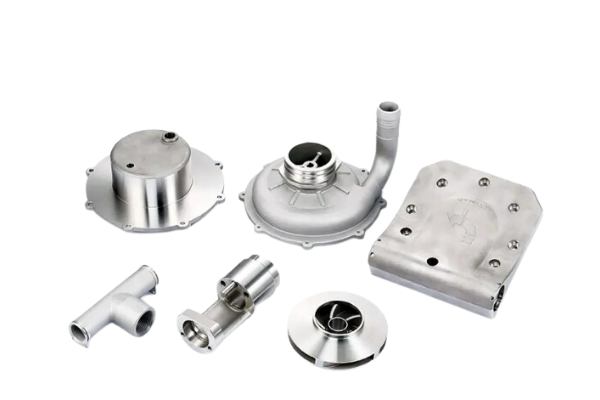

Aluminium CNC Service

CNC machining offers various industries numerous benefits, such as producing parts with exceptional mechanical properties and accuracy. Our 3-axis and 5-axis milling capabilities ensure your project is always perfectly completed. For lightweight strength and corrosion resistance from their materials, aluminum alloys are a perfect choice – low density plus natural protection make them ideal for extended-lasting use in any environment. What’s more? All this can be further enhanced via anodizing!

Contents of Aluminium CNC Service

Learn about Aluminum CNC Service – a revolutionary technique to create highly detailed customized products with precision and accuracy. Perfect for any application, this powerful service offers countless possibilities and opportunities!

Gain a thorough knowledge of the benefits and drawbacks to utilizing Aluminum CNC Services, including machining precision guidelines.

If you need specific aluminum alloys for your next project, ETCN has covered you with our comprehensive selection guide.

Part - 3 :Design and Quality Control

With our comprehensive overview of Aluminum CNC Machining, we will cover the design process, quality control measures, and wide-ranging applications.

Get high-quality, custom aluminum parts with fully customizable options and benefits for CNC machining.

From turn-around time and quality control systems to cost efficiency and experience in the industry, these essential tips help ensure you connect with a provider that meets your needs.

Part - 6 :Faqs

Our Aluminum CNC Service is a highly sought-after solution for laser cutting. With decades of experience, we provide reliable answers to commonly asked questions about our services so you can make an informed decision.

Part - 1:Overview Aluminium CNC Service

Aluminum CNC Service offers various machining options for all aluminum projects, from small-scale repairs to large production runs. Making sure your project is handled with precision and expertise, this service ensures quality results every time.

Advantages and disadvantages of Aluminium CNC Service

| Aspects | Advantages | Disadvantages |

|---|---|---|

| Aluminum Machining | Lightweight, excellent machinability, corrosion-resistant, and good thermal and electrical conductivity | Relatively low strength and hardness compared to other metals |

| Wall Thickness | Can be machined to very thin walls, as low as 0.5mm | May require specialized tooling and techniques for thinner walls |

| Tolerances | Can achieve tight tolerances up to +/- 0.002" | May require specialized fixturing and tooling for tighter tolerances |

| Max Part Size | Can accommodate larger part sizes up to 1 meter or more | May require specialized equipment for larger parts, which can increase cost |

| Other Considerations | Aluminum is highly recyclable and can be cost-effective for larger production runs. | Machining aluminum can generate a lot of heat, which can affect tool life and require cooling. |

What is Aluminium CNC Service?

• Aluminium CNC Service is a process of manufacturing customized components made from aluminum using computer-controlled machines.

• It enables high accuracy and precision in component fabrication, cost-efficiency, quick turnaround times, and unlimited design possibilities.

• Aluminum CNC Service is widely used in aerospace, automotive, electronics, medical, and construction industries for producing components for aircraft engines, wings, fuselages, lightweight engine parts, suspension components, body parts, etc, and electronic devices.

• The use of aluminum for manufacturing is set to increase due to its beneficial properties.

Aluminium CNC Service: Understanding the Process and Benefits over Traditional Methods

• CNC machining has revolutionized the metalworking industry by streamlining manufacturing and producing precise aluminum parts.

• The process involves using CAD software to create digital blueprints and program instructions for the machine, which cuts and shapes the aluminum block.

• CNC machining offers various benefits over traditional machining, including higher precision, faster speeds, and cost-effectiveness.

• Different types of CNC aluminum machining include milling, turning, drilling, and tapping.

• The tools used in CNC machines are made from high-speed steel, carbide, or diamond and come in different shapes and sizes.

• Coolant systems and work holding devices are also required for proper aluminum CNC machining.

aluminum CNC processing process

| Step | Process |

|---|---|

| 1 | Design and modeling: Create a 3D model of the part to be manufactured using CAD software. |

| 2 | Material selection: Choose the appropriate aluminum alloy based on the required properties of the part. |

| 3 | Material preparation: Cut the aluminum stock to the required size using a saw or other cutting tool. |

| 4 | CNC programming: Write a CNC program to specify the tool paths, cutting speeds, and other parameters. |

| 5 | CNC machining: Load the aluminum stock into the CNC machine and begin the machining process, which includes roughing, semi-finishing, and finishing operations. |

| 6 | Deburring: Remove any burrs or sharp edges left on the part after machining using various deburring tools. |

| 7 | Surface treatment: Apply a surface treatment to the part if required, such as anodizing, painting, or powder coating. |

| 8 | Quality control: Inspect the finished part to ensure that it meets the desired specifications and tolerances. |

| 9 | Packaging and shipping: Pack the finished part and prepare it for shipping to the customer. |

Part - 2 :Aluminum Alloy Selection

ETCN provides a comprehensive guide on selecting the perfect aluminum alloys for your project. With technical specifications, data sheets, and recommended applications, our selection guide ensures you get precisely what you need to create superior results.

Aluminum Alloy Selection: Considerations for CNC Machining

• When selecting an aluminum alloy for CNC machining, several factors must be considered to ensure optimal processability and performance.

• Machinability, corrosion resistance, strength, durability, weldability and anodizing capability should all be evaluated to ensure the desired output is achieved.

• Aluminum alloys such as 6061, 7075, 2024 and 5083 are popular choices due to their specific benefits and characteristics suitable for various applications.

• Industry professionals can select the most suitable aluminum alloy grade for their CNC machining to ensure superior performance for the final product.

common aluminum alloys for machining

| Aluminum Alloy | Physical Characteristics | Mechanical Properties | Application Fields | Surface Treatment Options |

|---|---|---|---|---|

| 6061-T6 | Medium strength, good weldability, excellent corrosion resistance, and machinability | Tensile Strength: 40,000 psi Yield Strength: 35,000 psi Hardness: 95 Brinell | Aerospace, automotive, and marine components, structural parts, and consumer products | Anodizing, painting, and powder coating |

| 7075-T6 | High strength, excellent fatigue resistance, and good machinability | Tensile Strength: 83,000 psi Yield Strength: 73,000 psi Hardness: 150 Brinell | Aerospace, defense, and high-performance applications | Anodizing, painting, and powder coating |

| 2024-T3 | Lightweight, excellent fatigue resistance, and good machinability | Tensile Strength: 68,000 psi Yield Strength: 47,000 psi Hardness: 120 Brinell | Aerospace, automotive, and structural components | Anodizing, painting, and powder coating |

| 5052-H32 | Good formability, excellent corrosion resistance, and weldability | Tensile Strength: 33,000 psi Yield Strength: 28,000 psi Hardness: 60 Brinell | Marine, architectural, and consumer products | Anodizing, painting, and powder coating |

| 6063-T5 | Good corrosion resistance, excellent formability, and good machinability | Tensile Strength: 27,000 psi Yield Strength: 21,000 psi Hardness: 60 Brinell | Architectural and consumer products | Anodizing, painting, and powder coating |

Part - 3 :Design and Quality Control

Delivering reliable aluminum CNC services requires meticulous design and a stringent quality control process. Following best practices and executing rigorous measures guarantees the highest-quality results, ensuring that clients get nothing but superior service every time.

Design for Aluminium CNC Service

• Aluminum is a highly versatile and reliable material for CNC machining applications due to its high strength-to-weight ratio, impressive durability, and excellent machinability.

• Designers must consider critical factors such as wall thickness, corner radius, tolerance, and surface finish when designing aluminum parts for CNC machining.

• Best practices include selecting the correct grade of aluminum material and the appropriate CNC machining process and choosing the right tool geometry, material, and coating used to achieve desired results.

• Designers should also be aware of challenges such as material deformation, chip formation, and difficulties achieving the desired surface finish.

Quality Control for custom aluminum machining

• Quality control in custom aluminum machining is necessary to ensure the accuracy and consistency of the final product.

• Documented procedures, standardized operating processes, manufacturing process monitoring, and experienced personnel help ensure quality.

• Coordinate Measurement Machines (CMM) and optical measurements such as 3D scanning can be used to measure physical geometrical characteristics and dimensions of products accurately.

• Automated techniques, cutting-edge software, calibration technologies, and ISO 9001 certification further help to minimize human error and maintain high levels of accuracy.

• With proper measures in place, aluminum CNC machining can efficiently produce high-quality products free from defects and meet specified requirements.

Applications of custom aluminum machining: An Overview of Industries and Markets

• Custom aluminum machining has become essential to manufacturing products for industries and markets such as aerospace, automotive, medical and dental, and consumer goods.

• Examples of aluminum parts produced through CNC machining include heat sinks, extruded profiles, gears and enclosures.

• The advantages of aluminum for CNC machining include its lightweight properties, corrosion resistance, high strength-to-weight ratio, and ease of machining.

• Custom solutions can be provided by reliable CNC machining service providers according to the client’s specifications, allowing for greater efficiency and quality in aluminum CNC processes.

Part - 4:Custom Aluminum CNC Parts

With ETCN, you can experience the ultimate in custom aluminum machining – get a product tailored to your exact specifications with top-of-the-line quality and unbeatable benefits.

requested information for custom aluminum CNC parts

| Custom Aluminum CNC Parts | Process | Materials Used | Advantages | Application Scenarios | Tolerances | Surface Treatment Options | Other Dimensions |

|---|---|---|---|---|---|---|---|

| CNC Machined Aluminum Parts | CNC Machining | Aluminum alloys (e.g. 6061, 7075, 2024, 5052, 6063) | Excellent machinability, high strength-to-weight ratio, corrosion-resistant, and good thermal and electrical conductivity | Aerospace, automotive, marine, medical, and consumer products | Up to +/- 0.002" | Anodizing, painting, powder coating, polishing, and more | Max Part Size: Up to 1 meter or more, Surface Finish: Ra 1.6 |

| Aluminum Sheet Metal Parts | Sheet Metal Fabrication | Aluminum sheets (e.g. 5052, 6061, 7075) | Lightweight, durable, corrosion-resistant, and excellent formability | Aerospace, automotive, electronics, and consumer products | Up to +/- 0.005" | Anodizing, painting, powder coating, and more | Thickness: Up to 0.25", Surface Finish: Ra 3.2 |

| Aluminum Die Casting Parts | Die Casting | Aluminum alloys (e.g. A380, A360, ADC12) | High strength, excellent dimensional accuracy, and good surface finish | Automotive, aerospace, and consumer products | Up to +/- 0.002" | Anodizing, painting, powder coating, and more | Max Part Size: Up to 2 kg, Surface Finish: Ra 1.6 |

| Aluminum Extruded Parts | Extrusion | Aluminum alloys (e.g. 6061, 6063, 6463) | Complex shapes, excellent structural integrity, and good surface finish | Architectural, automotive, and consumer products | Up to +/- 0.005" | Anodizing, painting, powder coating, and more | Max Part Size: Up to 10 meters, Surface Finish: Ra 1.6 |

| Aluminum Forgings | Forging | Aluminum alloys (e.g. 7075, 6061, 2024) | High strength-to-weight ratio, excellent toughness, and fatigue resistance | Aerospace, automotive, and industrial applications | Up to +/- 0.005" | Anodizing, painting, powder coating, and more | Max Part Size: Up to 100 kg, Surface Finish: Ra 3.2 |

Advantages of Ordering CNC Aluminum Parts

• CNC machining offers high precision and accuracy for tight tolerances and consistent quality.

• It is efficient in producing complex parts quickly and reducing production time and costs.

• Versatility allows for a wide range of aluminum parts, from simple to complex shapes and sizes.

• Aluminum alloys have excellent machinability, high strength-to-weight ratio, and good thermal/electrical conductivity.

• Custom designs and modifications can be achieved with CNC machining.

• Quality control measures are built into the machines, ensuring precise specifications are met.

• Variety of surface finishes (anodizing, painting, powder coating) available to meet specific requirements.

• Environmentally friendly due to less waste generated and lower energy consumption than traditional manufacturing methods.

Part - 5:Tips for choosing Aluminum CNC Service Providers

To guarantee a successful project, it’s important to select the right Aluminum CNC Service provider. Here are some top tips for finding the perfect partner to meet your needs and expectations!

- • When selecting an aluminum CNC service provider, looking for experience and expertise in the industry is essential.

- • Additionally, consider the skillset of their technicians and inquire about their experience, certifications, and training programs.

- • Quality of work should be a priority; make sure to ask about quality control processes and review samples of their work.

- • It is advantageous to choose a provider with advanced equipment and software for increased accuracy, speed, and efficiency.

- • Lastly, ensure that customer support is satisfactory, as it will facilitate addressing any concerns or issues arising during the process.

Frequently Asked Question

Pricing for Aluminum CNC Service

• Aluminum CNC machining is a popular choice for businesses due to its strength, durability, and affordability.

• Cost of aluminum CNC machining depends on the alloy used and complexity of parts being produced. Common alloys used include 6061 at $25 per block and 7075 at $80 per block.

• Running a 3-axis CNC machine costs around $40/hour, while operator salary can range from $30-$50/hour.

• Purchasing a CNC aluminum machining machine is expensive, typically between $7k and $25k.

• There are many providers available offering mass production aluminum CNC machining services with varying prices depending on their capabilities and experience; research is necessary to find one that meets needs and budget.

Can you CNC aluminium?

• Aluminium is a popular material for CNC machining due to its lightweight, high tensile strength, good corrosion resistance and ease of machinability.

• Four common aluminium alloys – 6061, 7075, 2024, and 5052 – are typically used in CNC machining processes.

• Each alloy has unique characteristics that make it appropriate for different applications.

• CNC machining aluminum allows for complex geometries due to its excellent material removal and surface finish characteristics.

• Overall, CNC machining aluminum is a great choice if you need high-quality parts with good strength and a lightweight profile.

What speeds can aluminium CNC cut?

• Aluminium CNC machines are able to cut from 10 up to 500 ipm (inches per minute), with a feed rate of 100 ipr.

• Speed depends on the type of aluminium and the complexity of parts being machined.

• Machine speed is also contingent upon its size, rigidity, and torque capacity.

Can you CNC plasma cut aluminum?

• CNC plasma cutting is an effective way to cut aluminum.

• Hot ionized gas directs the plasma stream toward the aluminum piece to achieve the desired shape.

• Plasma cutting offers high accuracy, fast production speeds, and low energy usage.

what is cnc aluminum

• CNC aluminum is metal cut and shaped using Computer Numerical Control (CNC) machines.

• The design is programmed into the machine’s software for precise cutting and shaping.

• CNC aluminum is used in a wide range of applications, from aerospace parts to furniture components.