Copper C101

Get all the details on Copper C101 with ETCN’s expert guide! From mechanical properties to common applications, we have you covered.

Details of Copper C101

| Property | Value |

|---|---|

| Alternative Names | Oxygen-Free Copper, OFHC |

| Density | 8.96 g/cm3 |

| Melting Point | 1083°C |

| Thermal Conductivity | 401 W/mK |

| Electrical Conductivity | 100% IACS |

| Elastic Modulus | 110-128 GPa |

| Yield Strength | 103-124 MPa |

| Tensile Strength | 220-250 MPa |

| Hardness | 45-65 HRB |

| Post Treatments | Annealing, Cold Working |

| Common Applications | Electrical Wiring, Conductors, Waveguides, Heat Exchangers |

Blogs related to CNC Machining Copper

Top 12 China CNC Machining Service Providers in 2023 You’ve...

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

Copper C101: Frequently Asked Question

• Copper C101 is an alloy renowned for its exceptional strength, machinability, and ductility, making it suitable for a variety of engineering, automotive, and electronics applications.

• Research at the Massachusetts Institute of Technology suggests that Copper C101 can withstand temperatures higher than other copper alloys without losing malleability or electrical properties.

• Its low levels of phosphorus provide superior corrosion resistance, which translates to increased longevity in extreme conditions such as aerospace applications or near bodies of water.

• According to statistics from the International Copper Association, over two million tons of Copper C101 were sold across various industries between 2017 and 2018 – showing an increase in recognition and utilization of this alloy’s full potential.

• Its versatility makes it an essential part of modern development processes, from large-scale construction projects to everyday electronics.

• C101 oxygen-free copper is a high-purity copper alloy renowned for its superior corrosion resistance and electrical properties, obtained through a process known as ‘oxygen-free electronic grade.’

• Its purity level ensures it keeps its electrical properties even after prolonged exposure to extreme temperatures or environmental conditions, in addition to better oxidation resistance than other copper alloys.

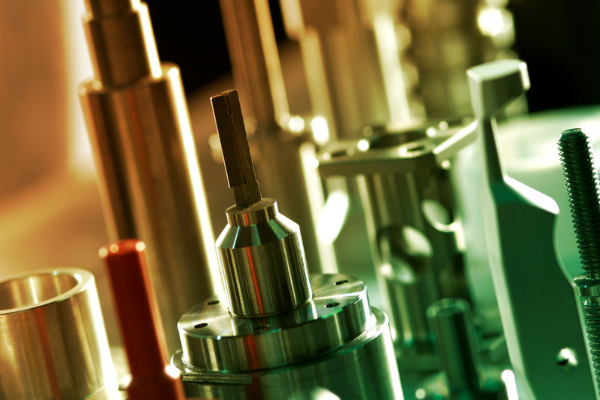

• C101 oxygen-free copper is easily fabricated, machined, drilled, and welded without losing its structural integrity, providing engineers with flexibility when designing with this material.

• It is one percent more conductive than traditional pure copper alloys and well-suited for the automotive, aerospace, and electronics industries.

• Recycling OFC101 copper helps reduce the world’s dependence on raw materials and reduces carbon emissions.

• Recycling is desired over new manufacturing, as recycled OFC101 contains fewer impurities and can be machined, drilled, and welded more efficiently, saving time and money.

• Everyone can take part in this initiative by responsibly disposing of electrical goods in designated metal recycling bins instead of leaving them in landfill sites.

• Doing this provides environmental and economic benefits, reducing our impact on the environment while providing savings.

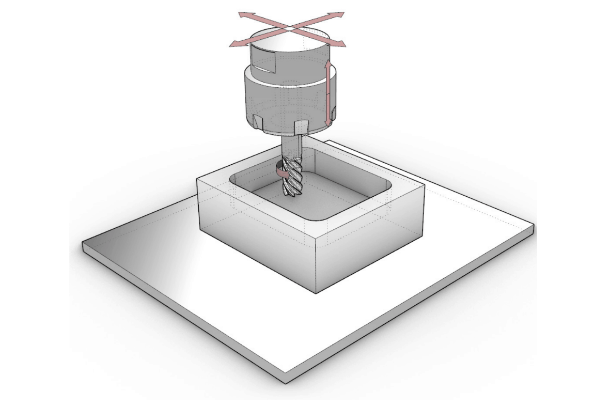

•Copper C101 can be processed using various methods such as cold working, annealing, and hot working.

•Cold working involves rolling, drawing, or forging copper at room temperature.

•Annealing heats the copper to a specific temperature and then rapidly cools it to produce specific properties.

•Hot working refers to heating the copper to a high temperature and then deforming it by extrusion or forging.

•Copper C101 is an ideal choice for use in environments with high temperatures or extreme weather conditions due to its superior corrosion resistance and mechanical strength.

•Copper C101 has a higher melting point than other alloys, making it resistant to thermal shock and cyclic temperature changes.

•Its excellent ductility also makes it suitable for use in applications requiring frequent flexing and bending in extreme climates, like air conditioning and wind turbine components.

•Copper C101’s oxidation resistance also makes it ideal for long-term exposure to acidic or alkaline environments.

• Copper C101 is an ideal choice for industrial and DIY projects due to its superior mechanical strength, corrosion and oxidation resistance, high melting point, and ease of formability.

• It is widely used in the manufacture of engine components, turbine blades, plumbing pipes, air conditioning units, dehumidifiers, suspension lines, cookware sets and utensils, furniture parts, door handles/knobs, and more.

• The combination of high-quality performance characteristics makes Copper C101 cost-effective and highly sustainable (as it can be recycled).

•Copper C101 is significantly stronger than other copper alloys, making it ideal for applications requiring parts that can withstand large amounts of stress or strain.

•Its high melting point also makes it resistant to thermal shock and cyclic temperature changes, which is essential in extreme conditions such as air conditioning units.

•Additionally, Copper C101’s excellent resistance to oxidation and corrosion makes it the preferred choice for plumbing pipes and components exposed to harsh environmental conditions.