Brass C464

Brass C464 is a versatile material with a range of properties. Learn all about it with ETCN’s expert guide and take your projects to the next level.

Details of Brass C464

| Property | Value |

|---|---|

| Alternative Names | Naval Brass, Alloy 464 |

| Density | 8.44 g/cm³ |

| Melting Point | 890-1000 °C |

| Thermal Conductivity | 62.1 W/(m·K) |

| Electrical Conductivity | 27-30% IACS |

| Yield Strength | 300 MPa |

| Tensile Strength | 600-800 MPa |

| Elongation | 30% |

| Hardness | 100-140 HB |

| Corrosion Resistance | Excellent |

| Post Treatments | Annealing, Stress Relieving |

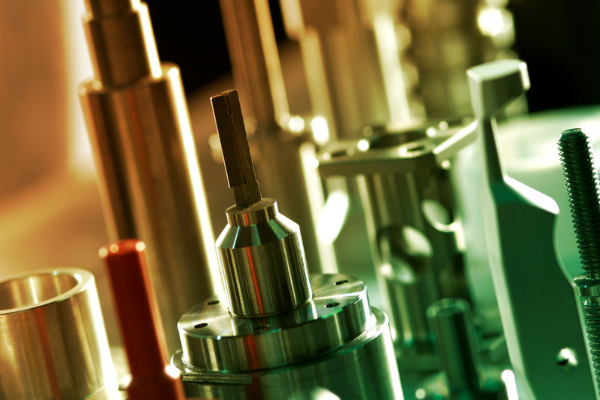

| Common Applications | Marine hardware, valves, pumps, propeller shafts, fasteners, gears |

Blogs related to CNC Machining Brass

Top 12 China CNC Machining Service Providers in 2023 You’ve...

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

Brass C464: Frequently Asked Question

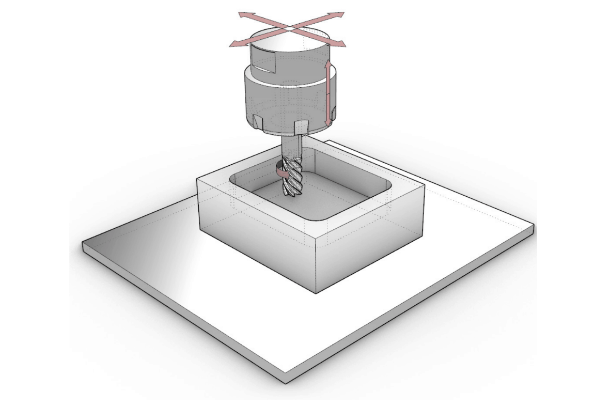

• Brass C464, also known as Naval Brass, is a copper-zinc alloy with a small amount of tin.

• It is resistant to corrosion in harsh environments, making it ideal for marine applications.

• The material is malleable, ductile, and easy to machine, making it suitable for parts such as propellers, shafts, valves, and fittings.

• Brass C464 has excellent weldability properties and is easy to braze or solder.

• Brass C464 is a type of naval brass that is a high-strength, corrosion-resistant alloy.

• Its key properties include excellent resistance to wear, fatigue, and stress corrosion cracking, making it suitable for use in harsh marine environments.

• It also boasts high thermal conductivity, high ductility, and low magnetic permeability.

• Brass C464 has good machinability and can be easily welded, brazed, or soldered using common techniques.

• The alloy is often used in various applications across industries such as marine, defense, aerospace, and oil and gas, among others.

•Physical and Mechanical Properties:

C464 brass has excellent strength and wear properties, making it highly resistant to mechanical stress, wear, and abrasion. The alloy has a high melting point of 910°C, making it well-suited for high-temperature applications. The thermal conductivity of C464 brass is high, making it easy to transfer heat. Its resistance to bending, torsion, and impact is exceptional, thanks to its high elasticity.

•High-Temperature Applications:

The outstanding mechanical and physical properties of C464 brass allow it to perform exceptionally well in high-temperature applications. In these scenarios, it’s widely used in heating, air conditioning, plumbing, and other related applications that operate under high-temperature conditions.

•Limitations and Tempering:

C464 brass is malleable and ductile, making it susceptible to bending and deformation when exposed to prolonged periods of high temperature. At approximately 593°C, the alloy’s elastic limit decreases significantly, causing a reduction in its bending, torsion, and impact resistance. As the temperature continues to increase, the tempering effect caused by prolonged exposure to high temperatures may ultimately render the C464 brass alloy useless.

•Brass C464 products require regular cleaning and polishing to maintain their appearance and prevent corrosion.

•Avoid exposing them to harsh chemicals or abrasive materials that can scratch the surface.

•In marine applications, rinsing with fresh water after exposure to salt water can help prevent corrosion.

• Brass C464, also known as Naval Brass, is a copper alloy known for its high strength, good wear resistance, and excellent corrosion resistance to seawater. It is composed of copper, zinc, and a small amount of tin, making it highly resistant to dezincification.

• The significant difference between Brass C464 and other copper alloys lies in its higher content of zinc and tin, which makes it more durable and resistant to corrosion, especially from saltwater.

• Compared to other copper alloys, Brass C464 also offers better machinability and weldability, making it suitable for various applications, such as marine hardware, fittings, and fasteners.