Acetal Plastics

Discover everything you need to know about Acetal Plastics with ETCN. Get expert information on its properties and applications.

Details of Acetal Plastics

| Alternative Names | Mechanical Properties | Physical Properties | Thermal Properties | Electrical Properties | Post Treatment | Common Applications |

|---|---|---|---|---|---|---|

| Polyoxymethylene (POM) | Tensile Strength: 70-80 MPa | Density: 1.41-1.43 g/cm³ | Coefficient of Thermal Expansion: 1.2-1.5x10^-^-4 K^-1 | Dielectric Strength: 20-25 kV/mm | Annealing | Gears, Bearings, Electrical Switches |

| Delrin | Yield Strength: 50 MPa | Melting Point: 175°C | Heat Deflection Temperature: 115°C | Volume Resistivity: 10^15 Ω·m | None | Medical Devices, Automotive Parts, Consumer Goods |

| Celcon | Tensile Strength: 65 MPa | Density: 1.41 g/cm³ | Thermal Conductivity: 0.24 W/m·K | Dielectric Constant: 3.8 | None | Conveyor Components, Gears, Valves |

| Hostaform | Tensile Strength: 62 MPa | Water Absorption: 0.25% | Heat Capacity: 1.75-2.0 J/g·K | Dielectric Strength: 24 kV/mm | None | Gears, Bearings, Pumps |

| Acetron | Tensile Strength: 85 MPa | Density: 1.42-1.44 g/cm³ | Coefficient of Thermal Expansion: 0.9-1.3x10^-5 K^-1 | Surface Resistance: 10^15 Ω/square | None | Food Processing Equipment, Medical Equipment, Gears |

Blogs related to CNC Machining Plastics

Top 12 China CNC Machining Service Providers in 2023 You’ve...

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

Acetal Plastics: Frequently Asked Question

•Acetal plastics, polyoxymethylene (POM), is a high-performance engineering thermoplastic.

•Acetal plastics are semi-crystalline polymers with excellent mechanical properties, including high strength, stiffness, and toughness.

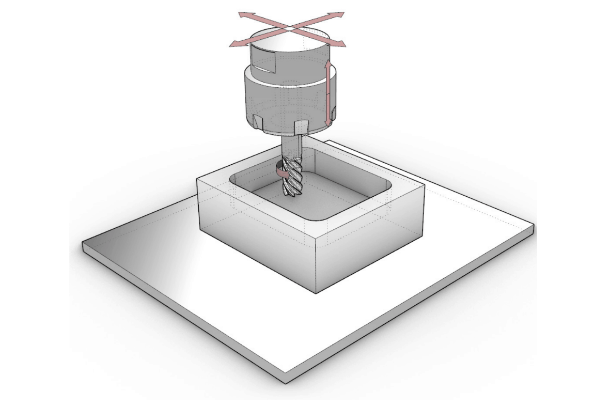

•Acetal plastics are easily machinable and have a low friction coefficient. They can be used in various industries, including automotive, electronics, medical, and consumer goods.

•High Strength and Durability: Acetals are robust and resistant to wear and abrasion, making them ideal for use in applications that require high strength and durability.

•Low Friction and Excellent Lubricity: Acetal plastics have low friction and excellent lubricity properties, making them ideal for use in applications that require easy sliding or movement.

•Chemical Resistance: Acetals have good chemical resistance and are resistant to many chemicals, including solvents and fuels, making them ideal for use in harsh chemical environments.

•Dimensional Stability: Acetals have a low coefficient of thermal expansion, meaning that they maintain their shape and size at different temperatures, making them ideal for applications that require dimensional stability.

•Electrical Insulation: Acetals are good electrical insulators, making them ideal for use in electrical applications.

•Acetal plastics can withstand high temperatures but to a certain extent.

•Acetal has good heat resistance properties and can handle continuous use at temperatures up to 180 degrees Celsius.

•However, exposure to high temperatures for extended periods can cause the material to degrade and lose some of its mechanical properties.

•It’s essential to ensure that the specific type and grade of Acetal plastic are suitable for the intended application and temperature conditions.

• Acetal plastics are safe for use in food and beverage applications. These plastics are widely used in the food industry, particularly in food processing and packaging, due to their excellent mechanical properties, durability, and resistance to chemicals and high temperatures.

• They are also safe for consumer use, as they are non-toxic, odorless, and tasteless, making them ideal for applications where direct contact with food is required.

• However, it is essential to note that acetal plastics have limitations when used with highly acidic or alcoholic foods, in which an alternative plastic material may be more appropriate.

• Acetal plastics are thermoplastics with excellent mechanical properties, making them suitable for various applications.

• The primary difference between the two is the way their molecular structure is arranged. Homopolymer acetal is comprised of repeating units of acetaldehyde, while copolymer acetal is composed of a combination of acetaldehyde and formaldehyde units.

• Homopolymers have higher strength and greater dimensional stability but are prone to cracking under high stress.

• Copolymer acetals have better resistance to thermal heat and chemicals, superior fatigue resistance, and lower moisture absorption. This makes them ideal for applications requiring greater flexibility.

•Acetal plastics can be recycled, but most recycling centers do not accept them as a regular commodity.

•Also, it is important to note that even if the plastic is recycled, the quality and properties may differ from the original material due to degradation or contamination.

•It is recommended to contact the recycling center in your area to inquire about specific recycling protocols and availability.