Precision CNC Milling

Best Precision CNC Milling service from China

Provide one-stop cnc precision milling solutions

Home » Precision CNC Milling

Source Factory

We can produce components with tight tolerances and exact precision that meet even the most challenging demands. From simple 2D cutouts to complex 3D geometries

Professional Services

We strive to exceed customer expectations by providing quality services backed by unbeatable accuracy and precision with our CNC milling solutions.

OEM Service

OEM services can help customers create parts tailored to their needs, including custom designs, special materials, and unique finishes.

Help & Support

We provide assistance with ordering parts, design feedback, material recommendations, and answers to any questions related to precision CNC milling.

High-Quality Rapid CNC Milling Service

ETCN provides high-quality rapid CNC milling services for both prototyping and production parts. Our experienced engineers and technicians use the latest technology to ensure accurate and precise results with quick turnaround times. Our services include 5-axis contour milling, accurate 4-axis machining, swarf airfoil, helical milling, barrel cams, and more. We also offer materials such as copper, bronze, magnesium, titanium, zinc, and plastic for custom-milled parts. With ETCN’s rapid CNC milling service, you can get top-notch results at competitive prices with fast delivery times.

Materials Available at ETCN

ETCN is a leading provider of copper CNC milling services. We specialize in the precision machining customer-designed copper components from cold-headed blanks, copper blanks, or solid copper bars. Our experienced engineers and technicians use state-of-the-art CNC machines to ensure accuracy and repeatability for all our copper CNC milling projects. Our advanced technology allows us to provide high-quality parts with excellent mechanical properties and tight tolerances. We also offer triple flute end mills designed explicitly for copper machining and other cutting tools optimized for machining material. With our commitment to quality and customer service, ETCN is your trusted partner for all your copper CNC milling needs.

ETCN provides high-quality bronze CNC milling services for a variety of applications. Our experienced team of engineers and technicians is dedicated to providing the best possible results for every customer. We use state-of-the-art CNC machines to ensure accuracy and precision in all our machining processes. With our advanced technology, we can provide custom parts with complex geometries and intricate details that meet your exact specifications.

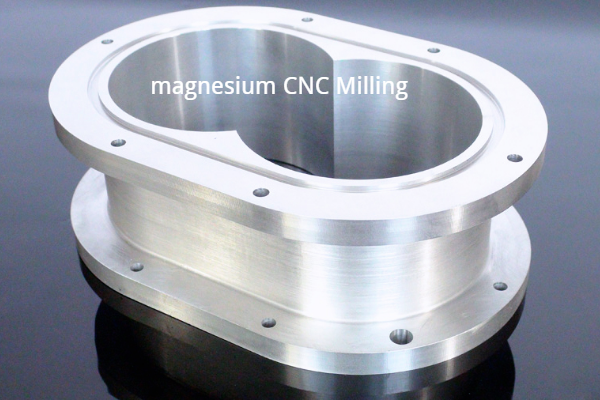

ETCN provides premium quality CNC machining magnesium services, allowing for tapping, drilling holes, fixtures, and other 3-axis CNC milling operations. Our experienced team of engineers is well-versed in various machining processes for custom magnesium alloy products, such as anodizing facilities that meet all aluminum and magnesium finishes requirements. We also specialize in CNC machining of prototypes, unique components, and small aluminum, magnesium, and zinc series with milling + turning capabilities. Furthermore, our operators have the precision accuracy for complex machine designs with critical tolerance requirements. With our expertise in aerospace, precision CNC, machinery manufacturing, and metal stamping fields since 2010, ETCN is your go-to provider for all your magnesium CNC milling needs.

ETCN is a leading provider of Titanium CNC milling services. Our experienced team can work with different grades of titanium and provide precision machining for a wide range of applications, including medical, aerospace, automotive, and military. We use advanced CNC machining centers to ensure dimensional stability and tight tolerances. Our services include sandblasting, anodizing, electroplating, and zinc plating for a smooth finish. With over ten years of experience in the industry, we guarantee quality results that meet your exact requirements.

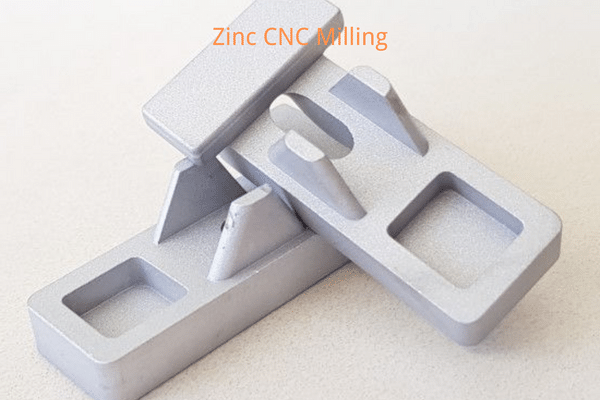

ETCN is a leading provider of zinc CNC Milling services. We specialize in providing custom machining services for zinc parts, including CNC milling, turning, drilling, reaming, and tapping of holes. Our experienced engineers and technicians have the expertise to deliver high-quality results with quick turnaround times. We use advanced CNC machines and cutting-edge technology to ensure accuracy and precision in our machining processes. Our competitive pricing and reliable customer service make us the perfect choice for all your zinc CNC Milling needs.

Applications of Precision CNC Milling

Wide Range of Application Scenarios

Precision CNC milling is a manufacturing process that involves using computer numerical control (CNC) machines to shape and cut materials with extreme accuracy. This process is used in various industries, from aerospace and automotive to medical and consumer products.

Manufacture complex shaped parts

CNC milling creates components with complex shapes, such as turbine blades, medical implants, and intricate molds. It can also produce parts with tight tolerances, such as those in the aerospace industry. The precision of CNC milling allows for making highly accurate details that are often impossible to make using traditional machining methods.

Reduce costs and improve efficiency

In addition to its precision capabilities, CNC milling offers several advantages over traditional machining techniques. For example, it can create parts with complex geometries that would otherwise require multiple operations or specialized tooling. It also eliminates the need for manual labor, which can help reduce costs and improve productivity.

Technical Parameters of China Precision Milling

| Machinery | 5 | |

|---|---|---|

| Material | Alloys Steel | Bronze Alloys |

| Aluminum Alloy | Stainless Steel | |

| Copper | Carbon Steel | |

| Brass | POM/PA | |

| Features | Deburring | Drilling |

| Tapping | Milling | |

| Threading | Boring | |

| Grinding | Knurling | |

| Maximum Dimensions | 800mm*500mm*550mm | |

| Milling Tolerance | ±0.005mm | |

| Inspection Capabilities | CMM | Projector |

| Imaging Measuring Instrument | Hardness | |

| Metallographic Microscope | Non-destructive Equipment | |

| Automatic Thread Inspection Equipment | ||

| Surface Finished | Zinc Plated | Sand Blasted |

| Nickel Plated | Blacking | |

| TD Coating | Phosphating | |

| Dacromet | Zinc-Nickel Plating | |

| Thread | UNF | UNC |

| NPT | SAE | |

| Metric | BSPP | |

| BSPT | JIS | |

| DIN | G | |

| R | ZG | |

| Certification | ISO9001-2008 | ISO/TS16949 |

The Ultimate Guide to Precision CNC Milling

Are you looking for the ultimate guide to precision CNC milling? If so, you’ve come to the right place. As an experienced manufacturer providing cnc milling services for more than 20 years, we understand the importance of precision and accuracy in CNC machining parts and services. In this ultimate guide, we’ll review everything you need about online CNC machining services, custom CNC machining services, CNC milling machines, and more!

What is precision milling?

Precision milling is a process that utilizes advanced cutting tools and computer numerical control (CNC) technology to achieve high-accuracy machining. It is essential in various manufacturing industries, including aerospace, automotive, and medical device manufacturing. This type of machining allows for producing highly accurate and complex parts from different materials ranging from metals to plastics.

Precision milling involves using CNC machines programmed with specific instructions for the part being made. The machine follows these step-by-step instructions to cut the piece from a workpiece material. The cutting tool must be precisely positioned before each cut is made to ensure accuracy. The result is a right-sized,, shaped part that can be used in many applications.

Unlike traditional milling machines, CNC machines can make more intricate cuts than manual ones. Allows them to provide higher levels of accuracy and precision throughout the entire machining process. Furthermore, CNC machines allow for automated operations once programmed; they will continue producing parts without further intervention. This increases efficiency and improves overall quality because all steps are carried out with high levels of consistency.

The precision milling process involves several steps depending on the material being worked with and what kind of product needs to be produced. Every effort must be carefully planned for a successful final product outcome, from programming instructions into the CNC machine to using various kind of cutting tools such as drills or end mills. While manual mills exist today for smaller projects, most businesses turn towards precision milling services as they provide increased accuracy and production speed that cannot be matched by manual methods alone.

Many third-party options specialize in providing top-tier milling services at competitive prices for businesses that have access to CNC machining centers but may not have experience setting up their precision milling operations. By outsourcing this service, companies can save money while ensuring their products meet the highest accuracy and quality control standards — especially if they require complex geometries or tight tolerances on finished parts.

In conclusion, precision milling is a critical process within many industries due to its ability to produce highly accurate parts quickly and efficiently, thanks to advances in CNC technology over recent decades. Whether you need one-off prototypes or large quantities of features swiftly built at scale, turning towards experienced and reliable third-party providers is often the best route forward when it comes time to start manufacturing your designs into real-world products!

What is CNC precision technology?

Introduction:

CNC precision technology is a process of machining metal, plastics, or other materials using computer numerical control (CNC) machines. The process is known for its accuracy, repeatability, and ability to make complex components with high precision and repeatability. CNC precision technology enables the production of highly accurate parts with minimal manual labor. This makes it ideal for industrial applications such as aerospace, automotive, medical, etc. In this blog post, we’ll explore CNC precision technology, its benefits and application areas, and how it works in more detail.

What is CNC Precision Technology?

CNC precision technology is a type of machining that uses computer numerical control (CNC) machines to cut metal, plastic, or other materials into precise shapes with high accuracy and repeatability. Unlike traditional machining methods such as drilling or milling, which require manual labor and time-consuming setup procedures between each operation, CNC machining eliminates human intervention by controlling the cutting process via computer software. Instead of using pre-defined cutting tools like drill bits or milling cutters to perform tasks like hole drilling or slot making, CNC machines use small rotating tools called “end mills” along with an onboard computer program to precisely create complex shapes out of material faster than manual machining methods can produce them.

Benefits of CNC Precision Technology

There are several advantages to using CNC machining for industrial manufacturing processes:

• Increased accuracy – Since the cutting tool does not require constant readjustment from operator interventions such as changing drill bits or repositioning items on the table saws, CNC machines can achieve a level of accuracy that older machining techniques could not match. This allows manufacturers to produce parts with higher quality standards and reduce waste due to inaccurate measurements or poor part finishings.

• Reduced lead times – With CNC precision technology, manual intervention is unnecessary when performing operations, drastically reducing lead times and improving overall productivity levels in production lines since labor-intensive tasks can now be automated instead of performed manually. Additionally, multiple parts can be produced simultaneously using a single machine, reducing production times significantly compared to manual assembly processes.

• Improved design flexibility – Unlike conventional machining techniques, which rely on standard templates to create predictable results such as holes in round or square shapes, CNC machines have far more advanced capabilities allowing them to create complex three-dimensional designs without having to adjust templates constantly, which results in improved design flexibility giving engineers greater freedom when crafting their desired components compared to traditional methods restricted by set templates and limited versatility.

Applications Areas

CNC precision technology has become increasingly popular among industrial manufacturers due to its wide range of beneficial features mentioned above; some popular industrial application areas include aeronautics & aerospace engineering, automotive industry manufacturing processes such as engine part fabrication & component stamping, medical device production, including orthotics & prosthetics creation; consumer product development such as electronics housings & custom furniture pieces; as well as general prototyping services used in various sectors including educational institutions & start-ups looking for low-cost product development options.

How Does it Work?

The basic principle behind how CNC machines work is quite simple – an electronic control unit (ECU) drives motors that move mechanical parts such as carriage rails & spindles accordingly depending on commands given by the user through their machine’s programming software package based on edited CAD drawings produced beforehand; ultimately resulting in precise cuts being made at predetermined locations on stock material without any human intervention whatsoever during the operation while still providing consistent quality results every time regardless if different operators input different settings into their machine’s interface every time they run it due to its simplistic nature and easy usability which provides even first time users with reliable results quickly & efficiently without having any prior experience operating these types of machinery before entering into this field.

Conclusion:

In conclusion, precision cnc milling technologies offer many advantages over conventional methods from increased accuracy levels due better repeatability factors enabling manufacturers create more intricate components faster than ever before while also reducing lead times drastically thanks automation taking over labor intensive operations previously done manually; all this combined together with improved design flexibilities coming from newer more modern functions integrated into these devices give engineers greater freedom when designing their desired products compared previous restrictions set forth by old fashioned analog equipment thus proving why more businesses around world are turning towards adopting these latest advancements within industry today help increase their operational speeds increasing output levels while also lowering costs significantly across board resulting better bottom line profits being realized all around board eventually leading stronger competition between companies leading Towards brighter future ahead us all!

What is the difference between CNC machining and precision machining?

CNC and precision machining are two distinct processes for producing components, but they have many similarities. Both methods involve using computers to control cutting tools on metal or other materials to create precision parts with a specific level of accuracy. However, there are some critical differences between them.

First, CNC machining uses computer numerical control (CNC) machines which allow for automated operation, precise dimensional accuracy, and repeatability. The device is programmed with a language called G-Code which directs it to cut specific shapes or features into the workpiece. In contrast, precision machining requires manual tooling by a skilled operator who manually sets up the tools according to their experience and expertise. This allows for greater flexibility in part design than CNC machining since there is more room for customization based on individual skills and preferences.

Second, while both processes require similar levels of precision, CNC machining typically offers higher levels of accuracy due to its automated nature. By using a computer-controlled machine, tighter tolerances can be achieved without sacrificing quality or consistency. Precision machining also offers high precision but may require additional grinding or finishing steps if the parts require exact specifications beyond what the manual machine can provide alone.

Thirdly, CNC machined parts have less material waste compared to those produced with precision machines because they eliminate any potential human error that could lead to mistakes while manufacturing. The programmed process ensures that each part created from start to finish is identical in size and shape, reducing material costs by eliminating unnecessary wastage. However, precision machined products often require more post-processing, such as polishing or honing, before achieving final product characteristics due to human error during the setup or execution of operations on manual machines.

Lastly, when selecting between CNC and precision machining services, you should consider cost and the time needed to complete your project – CNC machined components are usually more expensive than those produced through manual methods. However, they offer faster turnarounds due to their automated process, while precision parts may take longer due to their manual setup and extra finishing steps required for exact specifications.

In conclusion, CNC machining is an excellent choice for high-volume production runs where consistent accuracy is essential. In contrast, Precision Machining is ideal for small batches or custom-designed parts where specific details need extra attention to meet exact specifications. Choosing your manufacturer carefully based on your requirements is critical to get precisely what you need at an optimal price point, depending upon budget constraints and timeline expectations.

How accurate is CNC milling?

CNC (Computer Numerical Control) milling is a precise machining process for cutting and shaping metal, plastic, and other materials. This technology has become an invaluable tool for many industries due to its accuracy and efficiency. The accuracy of CNC milling depends on several factors, including the number of axes, the type of tooling used, the material being machined, and the programming software. This article will discuss how accurate CNC milling can be and what steps should be taken to ensure precision results.

The most critical factor in determining the accuracy of CNC milling is the number of axes available on the machine. Most machines have three or four axes; however, some devices have up to five or six axes, enabling tighter tolerances. The more axes a machine has, the greater its capacity for intricate cuts and shapes with high accuracy. Furthermore, machines with four or more axes can reproduce complex curves and shapes with minimal errors.

In addition to the number of axes, another major factor affecting CNC accuracy is the tooling used. Generally, higher-quality materials such as carbide or diamond-tipped tools are more precise than those made from less durable materials like steel or aluminum alloys. Additionally, using more extensive diameter tools can provide greater rigidity which helps reduce chatter and vibration that can affect surface finish quality. Some mills also utilize specialized tool holders such as collets or vises to minimize deflection and improve concentricity between cut features on different parts.

The machined material also affects CNC accuracy; softer materials are typically easier to machine than harder ones because they require less force when cutting, which helps prevent chatter caused by vibrations during operation. More complex materials require higher speeds for successful cutting, which increases friction, causing more vibration and resulting in poorer surface finishes if not appropriately managed by controlling rates during operation time according to material properties.

Finally, programming software plays a crucial role in achieving maximum precision from a CNC machine; CAD/CAM software enables users to create highly accurate 3D models that contain detailed information about cuts, such as depths and angles needed for each part’s final shape or size; these models then serve as reference points within an automated system providing control signals that direct the movements of cutting tools during operations without manual intervention whatsoever ensuring maximum accuracy throughout the entire machining process.

To conclude, how accurate a CNC milling job turns out depends on various factors, including but not limited to the number of available machine axes; quality & characteristics of tooling being used; properties & hardness level of material being cut; as well as CAD/CAM software employed during programming stage before actual machining operations taking place. With appropriate consideration given to each one mentioned above, it’s possible to achieve precise results when utilizing this powerful manufacturing technology!

What is the best CNC tolerance?

When it comes to CNC machining, the tolerance is an essential factor in determining the quality of the product. The tolerance refers to the allowable deviation from the specified dimension of a part. Generally speaking, the tighter the patience, the higher the cost and complexity of manufacturing. So what is the best CNC tolerance?

The answer depends on your specific application. For most applications, a standard tolerance of ±0.005″ is acceptable for CNC machining services. However, if you need high precision parts with tight tolerances, you may need to look for a manufacturer who can provide tolerances as tight as ±0.001″ or even less.

It’s also important to consider other factors, such as material type and finish, when selecting a CNC machining service provider. Different materials have different properties that affect their machining ability within specific tolerances. For example, aluminum has better machinability than steel and can typically be machined within tighter tolerances than steel or other metals. Additionally, some finishes require tighter tolerances than others to achieve desired results.

At our company, we specialize in providing precision CNC milling processing services with tight tolerances at competitive prices. We use advanced technology and high-quality materials to ensure that our customers get parts with superior accuracy and repeatability every time they order with us. Our experienced engineers will work closely with you throughout the process to ensure that your details meet all your requirements, including tight tolerances and exact specifications for each part of your project.

If you are looking for a reliable CNC milling service provider who can deliver superior quality parts within tight tolerances at competitive prices, please get in touch with us today! We look forward to hearing from you soon!

What are the 2 disadvantages of CNC?

One of the two major disadvantages of CNC machining is accuracy. While CNC machines can produce intricate and detailed parts with repeatable accuracy, they can only do so within certain limitations. Accuracy depends on the quality of the machine, its rigidity, and the precision of its cutting tools. If any of these three components is off, it will lead to an inaccurate part.

Another disadvantage of CNC machining is cost. Due to their complexity and high sophistication, CNC machines are more expensive than manual mills or lathes. Additionally, a highly trained operator is needed to program and operate a CNC machine, which adds to the overall expense. The setup costs associated with programming a job into a CNC machine can also be considerable; if the same position is run several times, there may be some savings due to less setup time for subsequent runs.

How can I make my CNC more accurate?

CNC Milling is a complex process that requires a high level of precision and accuracy. To get the best results from your CNC milling service, it’s essential to ensure that all the parts and components are accurately cut and machined. This blog post will discuss critical ways to make your CNC more accurate and ensure high-quality results.

Use High-Quality Parts:

The quality of your parts plays a vital role in ensuring accurate CNC milling results. High-quality details are more precise and provide better performance for CNC machinery. It’s also important to use features that match the specifications of your machine to get consistent results.

Follow a Proper Set-Up Process:

Proper set-up is essential for accurate CNC milling results. Follow a detailed setup process, including setting up tools, programming commands, manually calibrating tools, and double-checking parameters before cutting.

Use Up-To-Date Software:

Using outdated software can lead to inaccurate results or delays in production times due to incorrect code being sent to the machine. It would be best if you always use up-to-date software with bug fixes applied as soon as they become available not to compromise the accuracy or efficiency of your CNC machine operations.

Clean Your Machine Regularly:

Keeping your machine clean helps improve its accuracy by eliminating any dust accumulation that may interfere with its operation or cause it to drift off course when cutting materials. Regularly clean out chips and dust from inside and outside the machine using compressed air or other appropriate tools, such as vacuum cleaners specifically designed for this purpose.

Utilize Simulation Software:

Simulation software allows you to run simulations of your workpiece before actually running them on a real machine which can significantly improve accuracy levels by identifying potential errors early on in the process before they become costly mistakes when physically machining a part on an actual machine tool. If used properly, this software can help you save time, reduce scrap rates, save money, and increase efficiency in your CNC milling operations.

Invest in Quality Tools/Cutters:

Investing in quality cutters helps ensure that cuts are made accurately as possible every time around. Low-quality blades can lead to inaccurate cuts due to wear over time, decreasing overall accuracy. You should invest in high-quality blades designed for optimal performance with CNC machines to not compromise accuracy or speed when cutting different materials.

Conclusion: Making your CNC more accurate requires attention and care at each step of the manufacturing process – from selecting quality parts, properly setting up your machines before using them, using updated software, cleaning regularly, utilizing simulation software, and investing in quality cutters – all these steps play an essential role in ensuring precision and accuracy during CNC milling operations. If followed correctly, these tips should help improve production speeds while providing finesse and detail consistent throughout each project, regardless of the machining complexity or material type.

How precise is CNC machining?

CNC machining is integral to modern manufacturing, offering precision, accuracy, and speed in various applications. But how precise is CNC machining? The answer depends on the complexity of the machined parts and the type and quality of the machinery used.

The most precise CNC machining can be achieved through five-axis milling processes, allowing highly intricate parts with complex geometries to be produced. These processes involve positioning each axis of a cutting tool at different angles and orientations to create complex shapes and achieve desirable levels of accuracy. This type of Machining allows for more complex geometry than traditional three-axis milling processes, resulting in greater accuracy and repeatability over multiple batches.

When measuring the precision of CNC machining, it’s essential to consider both dimensional accuracy (how close two points are in size) and positional accuracy (the relative distance between two points). The former can generally be achieved with extreme precision, while the latter usually has an average tolerance level ranging from 0.01 to 0.02mm, according to International Organization for Standardization (ISO) standards. This means that when working within these tolerance limits, a CNC machine will produce components with no noticeable discrepancies or imperfections at a microscopic level.

In addition to accuracy, other factors affect the precision of CNC machining, such as cutting speed and feed rate – both of which should be set according to the nature and complexity of each project. The quality of cutting tools is also paramount, as poor-quality tools can generate heat which can expand or deform parts during production, thus compromising their dimensional integrity.

Ultimately, it’s worth noting that there will always be a certain degree of human error when operating any machinery, including CNC machines, so having experienced personnel who understand how these machines work is essential in achieving maximum results – especially when dealing with high-precision projects!

How accurate is CNC turning?

CNC turning has become increasingly popular due to its accuracy and repeatability. The accuracy of CNC turning depends on several factors, including the quality of the machine, the type of tooling used, and the operator’s skill. With modern CNC machines, it is possible to achieve tolerances as low as 0.001 inches (0.025 millimeters).

The accuracy of CNC turning also depends on the material being machined. More complex materials require more precise cutting tools and higher speeds for optimal results. Soft materials can be machined with less precision but may require slower speeds or additional passes over the same area to achieve desired results.

In addition to accuracy, CNC turning also offers repeatability, allowing for consistent production of identical parts without having to re-program each piece individually. This makes it ideal for mass production applications where multiple copies of a single work are required quickly and accurately.

Overall, CNC turning is an incredibly accurate method for producing complex shapes and components with tight tolerances and repeatability that can be relied upon time after time.

Is CNC more accurate than manual machining?

CNC milling is a popular machining process used in metalworking and woodworking. A router or cutting machine moves along a predetermined path to cut shapes from metal, wood, and plastic. CNC stands for computer numerical control and has been around since the 1950s. It is widely regarded as one of the most accurate machining processes available today, but is it more precise than manual machining? In this blog post, we’ll explore the debate surrounding this question and provide valuable insights into the accuracy of both processes.

Advantages of CNC Milling:

The primary advantage of CNC milling over manual machining lies in its accuracy and precision. CNC machines can follow complex instructions programmed into them using G-code and CAM software. This means that a CNC machine can produce high-precision parts with a shallow margin of error with proper programming. This makes them perfect for creating intricate details that require exact tolerances. Additionally, CNC machines have more extensive repeatability when compared to manual machines, meaning that they can pay identical parts time after time with minimal variations in shape or size.

Disadvantages of Manual Machining:

Manual machining is generally less precise and accurate than CNC milling because it relies on human input rather than programmed instructions. Manual machines require more setup time before they can be used effectively, increasing the potential for inconsistent results between different parts created by the same machine operator. Additionally, since manual processes rely on hand tools rather than automated machinery, they tend to be less efficient overall due to longer cycle times per part — meaning that more resources are expended during production than would be necessary with a CNC machine.

In conclusion, while both CNC milling and manual machining have advantages and disadvantages depending on your project requirements, overall, it’s clear that when it comes to accuracy and precision, nothing beats computer numerical control (CNC) milling technology. With properly programmed instructions from CAM software programs like Fusion 360 or Inventor HSM Pro Suite combined with modern-day automation technologies like robotic arms or automated tool-changing systems, CNC machines are capable of producing exact parts without any risk of human error from operators manually operating machinery or hand tools like drill presses or lathes. So if your project requires high accuracy, then no doubt investing in a quality CNC system will help you achieve your desired results faster while saving you money through faster cycle times per part produced compared to manual machining methods like drilling or tapping by hand.

Is CNC more precise than 3D Printing?

Introduction

When it comes to manufacturing, the accuracy of a product is paramount. As such, precision is an essential factor in any manufacturing process. In recent years, there has been increased interest in 3D Printing to create products with greater accuracy and detail than ever before. However, this technology cannot compare with CNC milling regarding precision and accuracy. In this blog post, we will discuss why CNC milling is more precise than 3D Printing and explore the features that make it beneficial for manufacturers.

What is CNC Milling?

CNC (Computer Numerical Control) milling is a subtractive manufacturing process that uses computer-controlled cutting tools to shape the material into intricate parts and components. The process involves feeding raw material into a milling machine, which then moves the cutting tool around the material to cut or shape it according to a predetermined design. This type of machining is often used for aerospace components, medical equipment, automotive parts, and other specialized items that require high levels of precision.

Advantages of CNC Milling Over 3D Printing

There are numerous advantages that CNC milling offers over 3D Printing when it comes to producing precise parts and components. Below are some of the key benefits:

• Accuracy – One of the significant benefits of CNC milling over 3D Printing is its ability to produce highly accurate results within minimal tolerances (i.e., up to 0.001 mm). This level of precision cannot be matched by many other methods, making CNC ideal for producing complex shapes with intricate details at high volumes quickly and efficiently.

• Material Options – Another advantage of CNC milling over 3D Printing is its ability to work with metallic and non-metallic materials at different hardness levels, including aluminum, brass, bronze, steel alloys, plastics, and composites. This gives manufacturers greater flexibility when choosing materials for their projects, as they can find appropriate solutions for almost any application or environment.

• Repeatability – With CNC machines being automated from start to finish, they can easily be set up to produce identical parts on multiple runs without requiring manual adjustment each time. This ensures consistent results every time, which helps reduce costs associated with trial-and-error processes during prototyping stages or large production runs where uniformity is essential.

Conclusion

Overall, when comparing 3D Printing versus CNC milling side by side, it’s clear that the latter offers significantly greater accuracy and repeatability due to its automated nature coupled with sophisticated tools for creating complex parts quickly and efficiently without compromising quality control standards or repeatability required in some industry sectors such as aerospace engineering or medical instrumentation manufacturing processes. For these reasons alone – not considering cost-effectiveness – manufacturers should seriously consider using this technology when dealing with sophisticated projects where precision counts more than anything else.

CNC Machining Faqs

CNC machining is used in various industries to create custom parts and prototypes quickly. It is also used in production parts as a reliable source of repeatable results with high accuracy. With rapid prototyping, custom-machined components can be created faster than ever before. One of the most significant advantages of CNC machining is its cost-effectiveness. It does not require too much time or resources to produce complex shapes and intricate details that can be difficult to achieve by hand.

Depending on your project requirements, CNC machining services use cutting tools such as drills, routers, end mills, and other special tools. Different machining processes may be used depending on your job specifications, including turning, tedious, threading, or d, rilling. These processes are programmed into the computer numerical control (CNC) machine, which allows multiple copies with very accurate dimensions and tolerances without human intervention once set up correctly for production runs. This automation saves labor costs and improves efficiency compared to manual methods, requiring skilled labor or tedious handwork during production.

In addition to cost savings due to automated machine programming, customers can receive fast turnaround times with short lead times while still getting high-quality components with tight tolerance levels made from materials such as aluminum or steel alloys or plastics like ABS or PETG filament composites. Investing in digital manufacturing technology has allowed us to offer competitive pricing while still providing high-level customer service throughout complex projects, whether large or small! We have built our reputation by consistently delivering quality machined parts with tight tolerances within short lead times at competitive prices!

We understand that choosing a reliable online CNC machining service provider is an important decision, so you must get all the facts before deciding who should take care of your custom CNC machining needs! Here at ETCN Milling Service, we have been helping our customers achieve their goal of producing precision parts for over two decades! We strive for excellence in customer service and product quality with every order processed through our facility! Our team of experienced cnc engineers works closely with each customer from concept design to production completion, ensuring attention to detail at every step! Our commitment toward complete customer satisfaction has earned us an outstanding reputation among our peers in the industry, which we will continue to strive to uphold each day!

CNC milling service china

If you’re looking for reliable online CNC machining services, look no further than ETCN Milling Service, where quality always comes first! We offer comprehensive services ranging from prototyping projects to large-scale production orders with materials such as aluminum alloys and plastics like ABS filament composites available for your convenience and complete post-processing options such as anodizing treatments available upon request!! Check out our website today for more information regarding our range of products & services, or call us anytime if you have any questions regarding our capabilities!

Precision CNC Milling is a manufacturing process that uses Computer Numerical Control (CNC) machine tools to create custom metal and plastic parts. This type of machining is precise and can produce intricate shapes with tight tolerances, making it ideal for applications that require high accuracy and repeatability. The CNC machining process begins with having a 3D model from computer-aided design (CAD) software. The CAD model is then used to create numerical instructions for the CNC milling machine, which controls all aspects of the machining process, including cutting tools, rotary axes, feed rates, spindle speeds, and coolant flow.

The first step in the precision CNC milling process is selecting the suitable materials for a specific application. This could include aluminum alloys such as 6061-T6 or 7075-T6 for strength, stainless steel for corrosion resistance, or injection molding plastic polymers such as ABS or PEEK for structural parts or housings. Once the materials have been selected, they are cut into sheets or blocks and loaded into the CNC machine and associated cutting tools.

The next step involves customizing these materials to meet customer specifications. This can include adding threaded holes and other features through subtractive manufacturing processes like drilling, tapping, slotting, and reaming; creating part geometries like slots and arcs by turning; and creating complex contours through milling operations on CNC mills or lathes. Multiple passes may be necessary to achieve desired results depending on project complexity and tolerance requirements.

Once all these operations have been completed, finish machining is performed to add surface finishes like anodizing or plating if needed. Finally, after completing quality inspections before delivery, the effects are corrected per the customer’s request before the final shipment from the CNC machine shop. In addition, cost reduction strategies are always considered by assessing factors such as material waste minimization, shorter cycle times due to reduced setup time, improving cutting parameters, etc., while using cnc services to reduce CNC machining costs.

In conclusion, Precision CNC Milling is one of the most widely used processes in the modern manufacturing industry due to its ability to produce highly accurate parts with complex geometries that maximize performance while minimizing costs. Furthermore, CNC machines provide high repeatability resulting in consistent quality across every production run. This makes it ideal for applications requiring detailed custom metal parts made from various materials, including aluminum alloys, stainless steel, plastic parts, etc.

Precision CNC Milling is essential for custom manufacturing metal and plastic parts. It is a widely used manufacturing process for producing custom metal and plastic components, medical devices, the electronics industry, automotive parts, and many other products. With the help of CNC machines, details can be machined with accuracy and repeatability, which was once impossible to achieve with conventional machine tools.

When choosing a CNC machining partner, it’s essential to consider their experience and capabilities in producing precision parts. You should ensure they have all the necessary equipment to complete your project, including standard CNC machines and specialized CNC mills. Additionally, it would be best to ask about the types of materials they can work with – such as aluminum alloys, plastics, composites, or steel alloys – and any unique treatments needed for your components.

A CAD file is usually required when designing components for CNC machining operations. This CAD file will generate tool paths to instruct the machine on how to move during cutting operations. These tool paths must be done accurately to ensure precision parts are produced. Experienced machine shops will have experienced engineers who can create accurate tool paths from your design files quickly and efficiently.

The benefits of CNC milling services include high-precision cutting with minimal visible tool marks on finished components and fast turnaround times due to its automated nature. Compared with manual milling operations requiring considerable skill from an operator, CNC milling offers superior quality in much less time, allowing for greater efficiency in production cycles.

CNC prototyping is also possible since 3-axis and 5-axis mills allow complex geometries to be machined in a single step without requiring multiple setups. This contributes further towards efficiency since only one form is needed instead of several (as would be the case when manual milling). In addition to being used for prototyping applications, CNC turning allows for faster cycle times than traditional lathes when producing custom automotive parts or other complex shapes requiring tight tolerances.

CNC milling offers many advantages over traditional methods of metalworking; however, experienced manufacturing partners should always be consulted before embarking on any project involving custom metal or plastic components so that they can weigh up whether other processes may be more suitable given the project specifications at hand.