cnc grinding service

ETCN is your best choice for cnc grinding service. We have an excellent team of professionals that are well-trained and have years of experience.

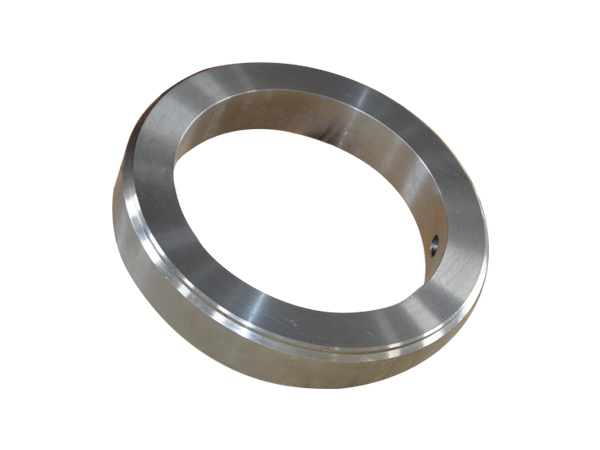

precision cnc grinding

cnc grinding companies From china

If you’re looking for a professional CNC grinding service, look no further than ETCN. Our experienced and certified operators can provide you with quality services at a competitive price. We offer a variety of services, including:

– CNC grinding

– Polishing

– deburring

– Raising patterns

– Texturing

– Customization

Welcome to our factory

Advantages Of ETCN’s precision cnc grinding

1. ETCN is the most precise CNC grinding company in the world.

2. ETCN offers a wide range of precision grinding services, from basic to highly specialized.

3. The company’s skilled technicians are able to provide accurate and repeatable results time after time.

4. ETCN’s precision grinding capabilities allow customers to achieve the highest possible standards of quality control.

5. The company’s commitment to customer service ensures that clients always have access to the best possible support.

CNC Grinding Capabilities

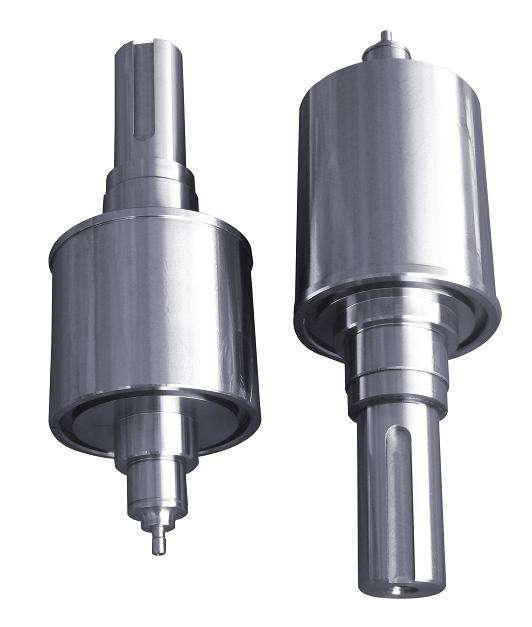

1. The CNC technology is combined with the grinder’s function so that the grinder’s function is diversified to meet the different needs of users and improve work efficiency. Then, to improve the processing quality of the workpiece.

2. The surface quality of the workpiece can be improved by grinding with different grinding tools. And through the use of numerical control technology to improve the processing efficiency of the complex workpiece.

3. If the hardness of the workpiece is relatively high, the grinder can also be used for processing, and the same is true for brittle materials. In addition, a good treatment effect can be obtained.

4. Through the computer software, to optimize the control of the equipment and eliminate human error, the CNC grinder in the processing accuracy can also be improved. Moreover, in terms of control, our CNC grinding services can also achieve this degree of accuracy.

Advantage of CNC Grinding

Precision

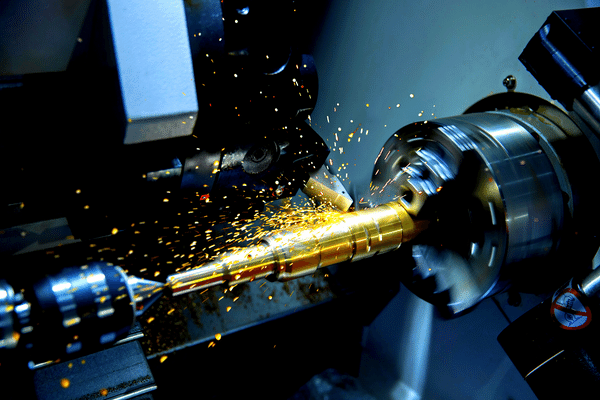

The high precision of our precision surface grinding services is the embodiment of CNC grinding machine quality; it directly reflects on the production quality of machining parts. Due to the high precision requirement of a CNC grinder, it is required to optimize the structure of the machine tool, adopt high-grade functional components, and have good static, dynamic, and thermal performance.

Composite

Multi-axis linkage control and multi-process compound grinding are some of the main technical characteristics of a CNC grinder. CNC grinding machines can realize the grinding of complex surfaces and composite cutting tools simultaneously.

High Speed

CNC grinding machine processing form is mainly high-speed, high-precision form grinding. The application of diamond grinding tools and CBN grinding tools, and other superhard material grinding tools put forward new requirements for the high-speed performance of grinding machines, such as the grinding wheel shaft generally adopts the motorized spindle with the speed of more than 10000 R / min; the machine tool is required to have excellent electromechanical coupling, servo optimization, and high acceleration performance. The application of direct drive components such as motorized spindle, torque motor, and the linear motor has become a new highlight of the high-speed performance of CNC grinder.

cnc grinding service Technical parameters

| Machinery | 3 | |

|---|---|---|

| Material | Alloys Steel | Bronze Alloys |

| Aluminum Alloy | Stainless Steel | |

| Copper | Carbon Steel | |

| Brass | POM/PA | |

| Features | Deburring | Drilling |

| Tapping | Milling | |

| Threading | Boring | |

| Grinding | Knurling | |

| Maximum Dimensions | 6000mm*2000mm | |

| Inspection Capabilities | CMM | Projector |

| Imaging Measuring Instrument | Hardness | |

| Metallographic Microscope | Non-destructive Equipment | |

| Automatic Thread Inspection Equipment | ||

| Surface Finished | Zinc Plated | Sand Blasted |

| Nickel Plated | Blacking | |

| TD Coating | Phosphating | |

| Dacromet | Zinc-Nickel Plating | |

| Thread | UNF | UNC |

| NPT | SAE | |

| Metric | BSPP | |

| BSPT | JIS | |

| DIN | G | |

| R | ZG | |

| Certification | ISO9001-2008 | ISO/TS16949 |

Cnc Grinding Service : the Definitive Guide

Frequently Asked Questions.

what is cnc grinding?

CNC grinding is a process that uses computers and milling machines to create intricate shapes and designs out of metal. It’s an efficient way to manufacture parts quickly and with precision, making it ideal for everything from car parts to firearms.

what is cnc grinding machine?

A cnc machine is a computer-controlled machine that can cut and shape pieces of metal, plastic or other materials. It uses what’s called a rotary tooling system to move the cutting tool around the object being machined.

what is a cnc grinder?

A cnc grinder is a machine that uses computer-controlled cutting and grinding to create parts from a piece of metal. It is a more advanced version of a manual grinder, and can be used to cut parts from all types of metals, including aluminum.

how does a cnc grinder work?

A cnc grinder works by rotating a cutting tool around a workpiece. The cutting tool causes the workpiece to be chopped up and it is then levelled and trimmed.

how to run cnc surface grinder?

There are a few things you’ll need in order to run a CNC surface grinder. First, you’ll need a computer with a CNC control system and a software program like Mach3 or G-code. You’ll also need a machine that can cut surfaces and a CNC surface grinder itself. Finally, you’ll need some basic tools and supplies like cutting blades, a workbench, and clamps.

The first thing you’ll need to do is adjust the height of your machine’s spindle so that it’s at the correct distance from the workpiece. This will determine how deep your cuts will be. Once this is set, you can start inputting your G-code into the controller. G-code is a type of code that tells the machine what to do.

To start cutting, you’ll first have to set up your blade on the spindle. Make sure that the blade is facing towards the workpiece and clamp it down securely. Next, turn on your machine and wait for it to get up to speed before cutting. Keep an eye on your workpiece to make sure that it doesn’t get damaged!

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.