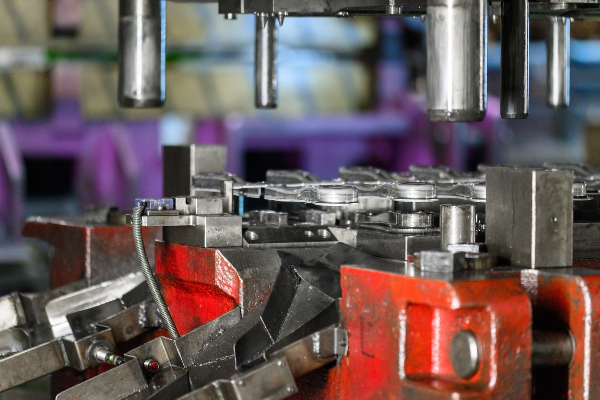

stretch forming sheet metal

Stretch forming sheet metal is a process that can be used to create components or pieces from heavy, bulky materials like steel.

What is stretch-forming sheet metal?

Stretch forming is a process that uses rolling and stretching movements to create an object from a metal sheet. The object can be in the form of a wire, cable, or strip. Stretch forming is commonly used to produce parts for aircraft and other vehicles.

Types of stretch-forming sheet metal

Stretch-forming sheet metal is a type of metal that can be stretched to form different shapes. This metal is often used in products such as car parts, aircraft parts, and prosthetic devices.

There are several types of stretch-forming sheet metal, each with its benefits. The most common type is the hot-rolled strip. This metal is formed into a long, thin strip and then heated until it begins to cool. The heat causes the metal to contract, making it possible to form different shapes.

Another type of stretch-forming sheet metal is the cold-rolled strip. This metal is formed into a shorter, thicker strip and then cooled slowly. The heat causes the metal to contract, but not as much as with a hot-rolled strip. This allows for more precise curvature and less distortion than a hot-rolled strip.

The final type of stretch-forming sheet metal is the tube form. This metal is formed into a long, thin tube and then heated until it begins to cool. The heat causes the metal to contract, making it possible to form more intricate shapes than any of the other types of stretch-forming sheet Metal.

The benefits of using stretch-forming sheet metal

Stretch-forming sheet metal is a great way to create custom parts or assemblies. It’s a versatile manufacturing process that can be used in a variety of industries. Here are some of the benefits of using stretch-forming sheet metal:

1. It’s an efficient way to produce customized parts.

2. It’s a fast process that can produce parts quickly and efficiently.

3. It’s a flexible manufacturing process that can be used to create parts with a variety of shapes and sizes.

4. It can be used to create parts that are strong and durable.

5. It’s an affordable process that can be used in a variety of industries.

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.