TOP CNC Machining Plastics supplier from china

ETCN supplies high-quality CNC Machining Plastics, as well as promotional products for your business.

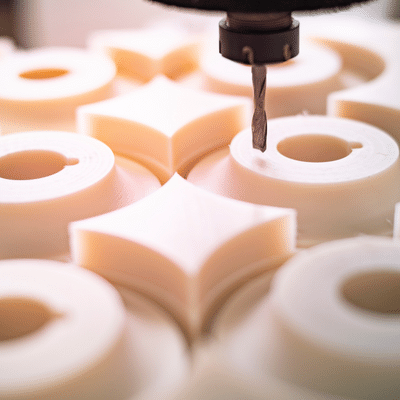

CNC Machining Plastics Services – Custom Machined Plastic Parts Manufacturer In China

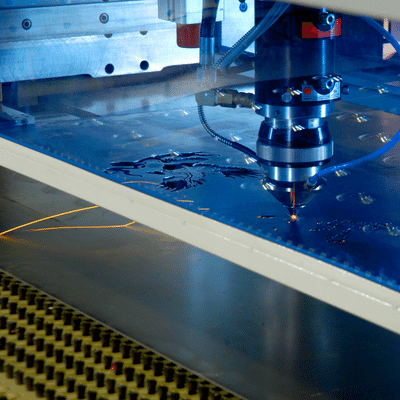

ETCN is a China-leading CNC parts manufacturer with more than 20 years of experience in precision plastic injection molding, metal stamping, and CNC machining. We are specialized in custom manufacturing mechanical parts with high quality and competitive prices.

We have excellent engineers and technicians, advanced equipment and technology. We provide one-stop service from product design to delivery at a competitive price to satisfy all your needs. Our professional sales team can help you with any questions you may have about our products or services.

ETCN has a large stock of raw materials for the fast delivery time, ensuring a smooth production process for our customers.

Why Choose ETCN CNC Machining Plastics Services?

ETCN is a China-leading CNC parts manufacturer, we specialize in developing and producing all kinds of plastic injection molds, plastic injection parts, and metal products.

ETCN has been committed to the development of CNC machining plastics for many years. We have a group of professional engineers who have rich experience in developing and producing plastic molds and plastic parts. They also have rich experience in solving technical problems in the field of production technology and mold design.

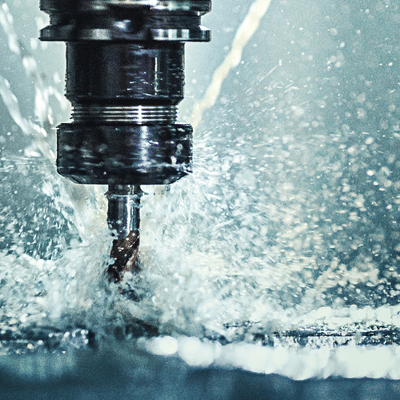

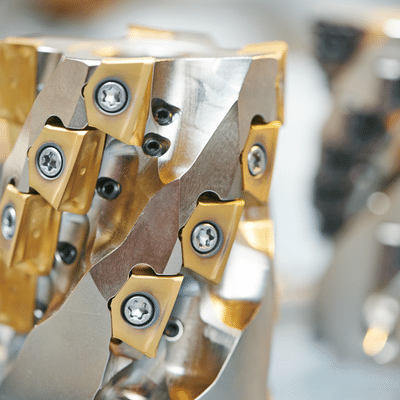

We have more than 100 sets of CNC machines, including vertical lathe, horizontal lathe, milling machine, boring machine, and other equipment. Our manufacturing capacity is 300 tons per month.

Our main products are CNC machining plastics, including carbon fiber plastics, fiberglass resin, acrylonitrile butadiene styrene (ABS), polystyrene (PS), polypropylene (PP), polyethylene terephthalate (PET), etc.

We will help you find an ideal solution, whether it’s a prototype or mass production project.

What Type of Plastic is used for CNC Milling?

The most common types of plastics used for CNC milling are:

Acrylic (ABS) – Acrylic is a hard, transparent material that has a wide range of applications. It is commonly used in a variety of engineering components, including lab equipment and medical devices. Acrylic can also be used as a substitute for glass in some applications.

Polycarbonate (PC) – Polycarbonate is a thermoplastic polymer that can be injection molded into various shapes. While it has many industrial applications, it is also popular among hobbyists and DIYers because it can be cut using a CNC milling machine.

Nylon (PA) – Nylon is another strong and durable plastic that can be machined with an industrial CNC milling machine. It has excellent chemical resistance and good impact strength, making it ideal for use in electrical connectors and other parts with high-stress points.

What are the common applications of plastic cnc milling?

The common applications of plastic CNC milling are:

1. Plastic injection molding is one of the most popular applications for plastic CNC milling. It is used with a large number of plastic materials including nylon, polyethylene and polypropylene.

2. Plastic CNC machining can also be used to create complex shapes in the field of automotive manufacturing and aerospace industries.

3. It can be used to make parts for electronic devices such as smartphones or laptops.

What Are the CNC Plastic Machining Materials?

The material used in the plastic machining process is dependent on the type of plastic to be machined. There are various types of plastic that can be used in the process.

The following are some of the most common plastics used in the process:

Acetal (Delrin)

This is a general-purpose material that is very popular among hobbyists, as it is easy to work with and relatively inexpensive. It has a high strength-to-weight ratio, making it ideal for applications where a high level of durability is required. It also has low moisture absorption, which makes it suitable for use in low-humidity environments.

Acrylic

Acrylic is a transparent plastic with a high refractive index. It is often used in the construction of aquariums, as it is both durable and easy to clean. Acrylic can be cut with a CNC router, but you will have to take extra precautions to protect the material from being scratched.

Acrylic can be cut using standard cutting tools such as carbide-tipped end mills and ball nose end mills. It is recommended that you use a high feed rate when cutting acrylic — up to 1/8″ per minute — and apply a coolant when possible.

Polycarbonate

This is another commonly used material because of its durability and strength characteristics. It has excellent impact resistance and can withstand temperatures up to 180 degrees Celsius without warping or melting.

Nylon

Nylon can be used for injection molding, extrusion molding, or blow molding processes. In addition to these three processes, it can also be made by the hot-molding process (only limited parts) or vacuum compression molding process (limited parts).

Polyethylene Terephthalate (PET)

Polyethylene Terephthalate (PET) is a thermoplastic polymer resin of the polyester family and is commonly used in fiberglass textiles such as fleece jackets, carpets, home furnishings, and more. PET can be machined with CNC (Computer Numerical Control) machines that use a toolpath to create the desired shape. It is commonly used in injection molds and other molding applications because of its strength and rigidity.

Polypropylene (PP)

Polypropylene (PP) is a thermoplastic polymer that belongs to the group of polyolefins. It is one of the most common plastics in the world and has many uses, including containers, packaging, automotive parts, ropes, and even medical devices. PP is often used to make 3D printed parts because it can be extruded at high temperatures.

The most commonly used plastic material for CNC machining is polypropylene (PP). This is very tough and durable plastic. It can be used for many different types of applications and is not too expensive to purchase.

Polypropylene has good wear resistance, but it does not stand up well to abrasion. It also has low impact resistance, which means that it can be easily damaged when dropped or hit by another object.

Polypropylene is suitable for most machining processes, including:

● Die cutting

● Injection molding (plastic parts)

● ABS/PC blending

● Extrusion (pipe and tubing)

Polystyrene (PS)

Polystyrene is a thermoplastic material that is used in a variety of applications. It is an excellent insulator, has a low coefficient of friction, and is very durable. Polystyrene can be machined using a milling machine or lathe.

The main properties of PS are:

Lightweight

Durable

Heat resistant

Flexible

PS is used in a wide variety of industries, including packaging, automotive, construction, and consumer products.

Polyvinyl Chloride (PVC)

Polyvinyl chloride (PVC) refers to a family of thermoplastic polymers that contain vinyl groups in their backbone chain.

The ability to mold and shape these plastics gives them many uses. They are often used for making toys, pipes, flooring, windows, doors, and more. The different shapes they can take make them ideal for creating molds of objects such as cars and other vehicles. Like other materials, they can be machined by CNC machines to create complex shapes that would otherwise be difficult or impossible to produce with traditional methods.

ABS plastic:

ABS plastic is a general-purpose engineering thermoplastic resin. It has good dimensional stability in heat and cold conditions; also has strong impact resistance and good wear resistance. It can be used for injection molding and extrusion molding processes. In addition to the above two processes, it can also be made by the hot-molding process and vacuum compression molding process.