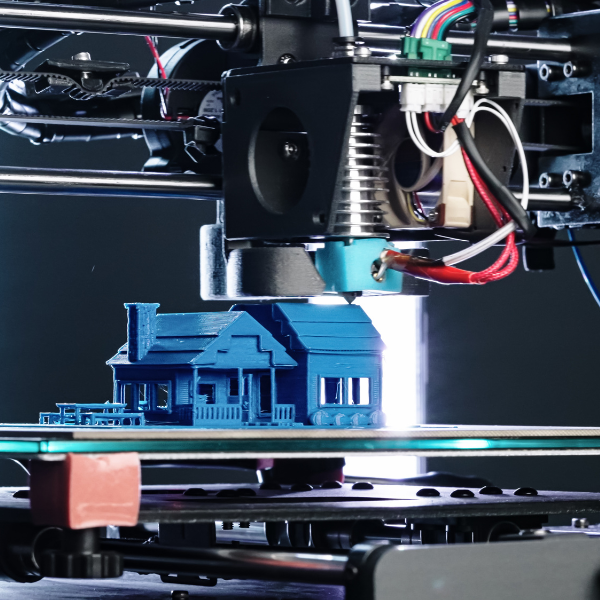

3d printing prototyping service

If you need a custom part, prototype or manufacturing services, 3D Printing and Prototyping Service is only a click away!

Home » 3d Printing Prototyping Service

Get an instant 3D quote today. Choose from a variety of materials for rapid prototyping and production.

ETCN is a professional online metal 3d printing service supplier. We have a professional team that can provide you with the best service.

We can make all kinds of metal 3D printing parts, including stainless steel, carbon steel, alloy steel, aluminum, and other non-ferrous metals, etc.

We apply a wide range of metal powder materials, such as Aluminum powder, Copper powder, and so on.

We have a QC team to inspect every product before shipment; We also provide an excellent after-sale service for our customers.

Why choose us for custom 3D printing?

We are one of the best custom 3D printing company in China. We offer high quality custom 3D printing services with affordable price.

Our advantages:

1. Our factory is professional in 3D printing industry, we have our own R&D team to develop new products and improve existing ones;

2. We have a long experience in manufacturing plastic injection molding parts;

3. Our sales team is professional, and they can give you a satisfactory answer for your questions during the process of communication;

4. We have our QC team, which will check every product before shipping to ensure every product meets our high-quality standard;

5. We will send you pictures of products before shipping to confirm if there’s any problem with products or not;

What is 3D Printing?

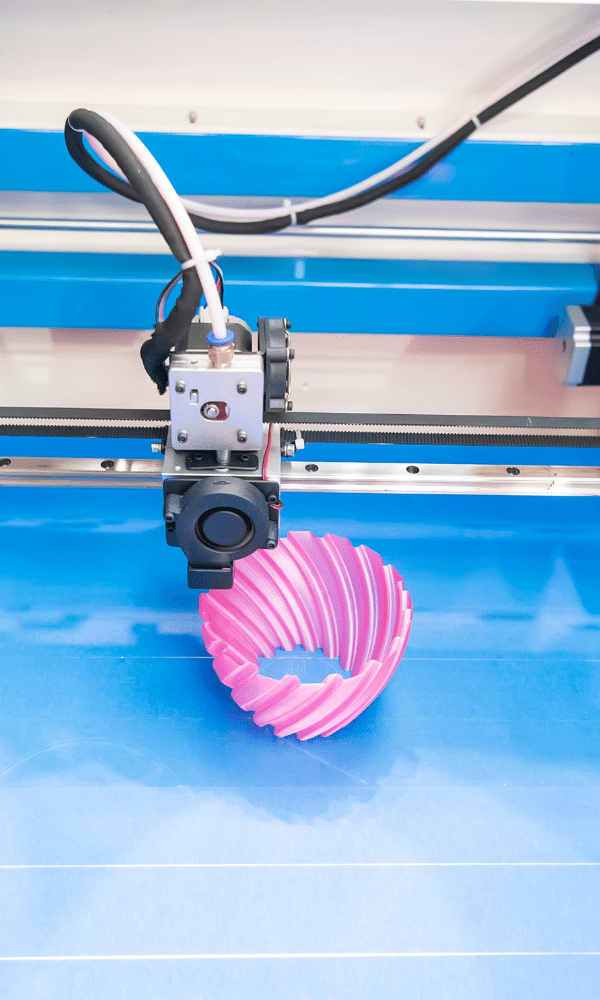

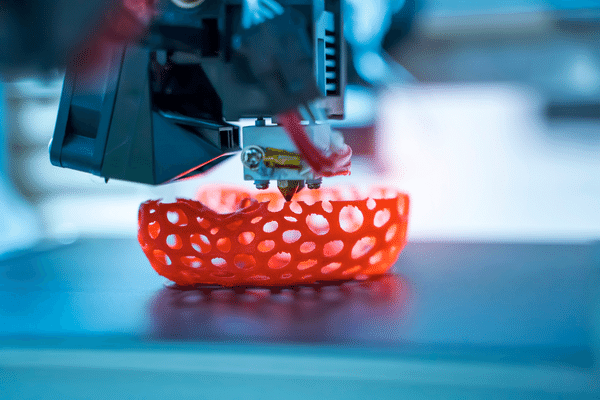

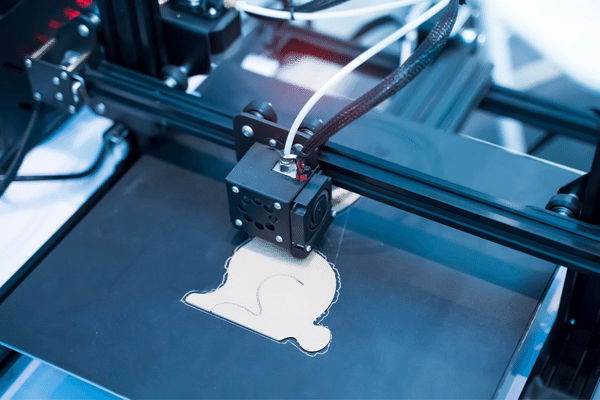

♦3D printing makes a three-dimensional solid object of virtually any shape from a digital model. This is achieved by laying down many successive thin layers of material, which are then joined to make one overall piece.

♦3D printing is also known as additive manufacturing. The technology has been evolving from 3D printing using plastics to include metals and ceramics and composite materials containing organic and inorganic components.

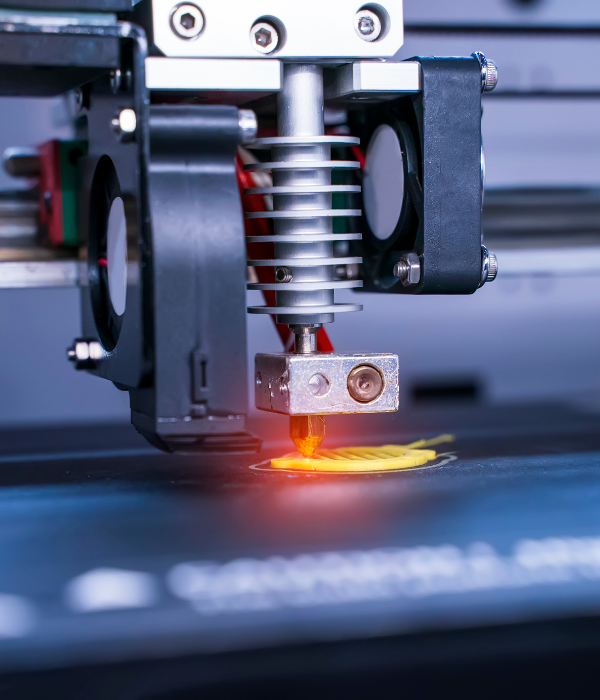

♦The most basic type of 3D printing is called Fused Deposition Modeling (FDM). With this process, molten plastic is deposited layer by layer onto a build platform, where it cools and solidifies. The next layer of plastic is deposited on top of the previous layer. After each layer cools, the platform drops down a certain distance, giving the newly formed object room to expand outward as it cools further.

♦3D printing is used in various applications and industries, including aerospace, automotive, dental, medical, footwear, and jewelry.

♦3D printing allows for more customization than traditional manufacturing processes, which enables companies to make products that are better suited for their customers’ needs and preferences. It also reduces the waste created during manufacturing because fewer parts are needed for complex products such as mobile phones or watches with moving parts.

Advantages of 3D Printing

The most important benefits of 3D printing are:

♦High-quality prototypes can be made quickly and cheaply.

♦ Designers can create complex shapes that would be difficult or impossible to manufacture using traditional methods.

♦Multi-part assemblies can be easily produced from a single file by combining multiple objects into one solid object.

♦ There are no tooling costs when producing small batches of parts or one-off designs.

How does 3D printing work?

The technology behind 3D printing is quite simple. It works by building up layers of material to create a three-dimensional object.

There are two types of 3D printers:

♦Fused deposition modeling (FDM) printers, which use plastic filament

♦Stereolithography (SLA) printers use a liquid resin that hardens when exposed to light.

Fused deposition modeling (FDM) printers are a class of 3D printers that uses a thermoplastic filament, typically PLA or ABS. The filament is heated until it melts and then extruded through a nozzle to build the object. FDM printers can be used to print functional prototypes and end-use parts with relatively low resolution.

Stereolithography (SLA) printers are the professional answer for high-quality, durable parts. They use a digital light processing (DLP) technology with a liquid resin that solidifies when exposed to laser light. The result is a part with an extremely smooth surface finish and minimal post-processing necessary to achieve it.

Types of material

1. ABS (Acrylonitrile Butadiene Styrene)

2. PLA (Polylactic Acid)

3. Nylon

4. Polycarbonate (PC)

5. Flexible Filament

6. Wood-like filament

7. Metal alloys

8. Ceramic, Glass and other specialty alloys

3D Printing Service stainless steel Overview

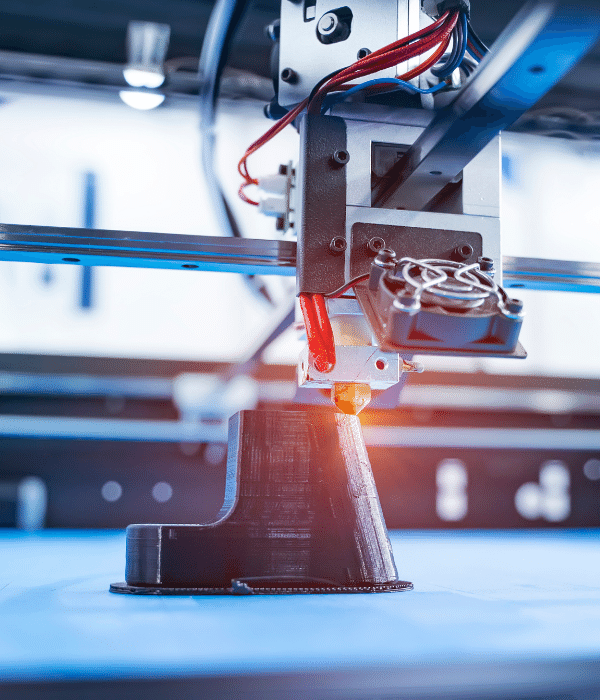

We provide the perfect 3D printing service for you. We can make your ideas come true with our high-quality 3D printer. The metal 3D printer is very popular in the industry because of its durability, strength, and flexibility. This metal 3D printer is a great choice for making metal parts or prototypes.

The advantages of our metal 3D printer:

1. Durability – Our metal 3D printers have a large build volume, which can be used to print all kinds of objects with complex geometries and intricate details.

2. Strength – The strong and stable steel frame prevents any distortion during printing.

3. Flexibility – We use industrial motors to control the movement of the X-Y gantry axis so that it is easier to print complex objects with smooth surfaces on our machine.

What is sheet metal 3D printing?

Sheet metal 3D printing is a technology that can produce complex parts from various materials. It has been used in aerospace, automotive, and medical industries for over 30 years.

Sheet metal 3D printing is an additive manufacturing (AM) or rapid prototyping (RP). It’s the process of creating physical objects by adding layers of material one on top of another. This allows designers to produce prototypes quickly without wasting time on tooling or machining costly molds.

How does sheet metal 3D printing work?

The sheet metal 3D printing process involves creating a CAD model using computer-aided design software such as SolidWorks or AutoCAD. The CAD file is then imported into the printer control software, where it’s sliced into layers, ready for printing. Each layer is built up using a laser beam that melts and fuses thin sheets of metal powder together. This produces a solid object which can be used immediately or further processed afterwards (e.g., drilling holes).

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.