Copper CNC Machining Services – Leading China Copper Parts Manufacturer & Company

If you are looking for China best Copper CNC Machining Services and Leading Copper Parts Manufacturer, ETCN is your right partner.

Home » Complete Guide to CNC Machining » CNC Machining Copper

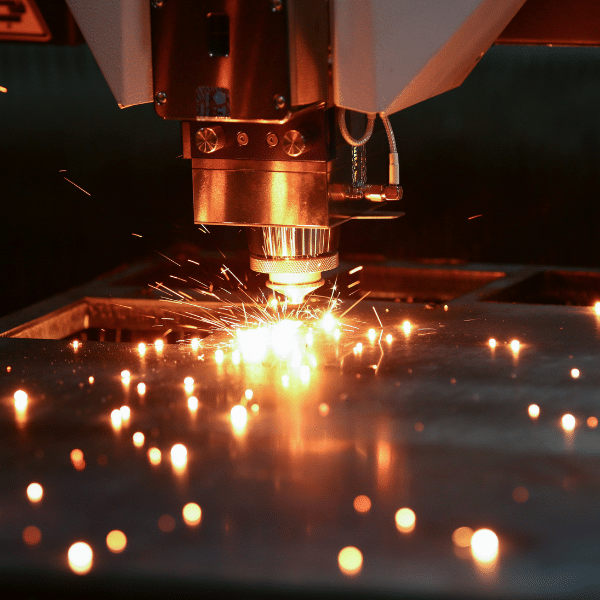

♦Copper CNC Machining Service is the process of manufacturing precision components and assemblies by cutting metal using a computer-controlled machine tool. It is an economical method of making metal parts, which was previously only possible with expensive hand tools.

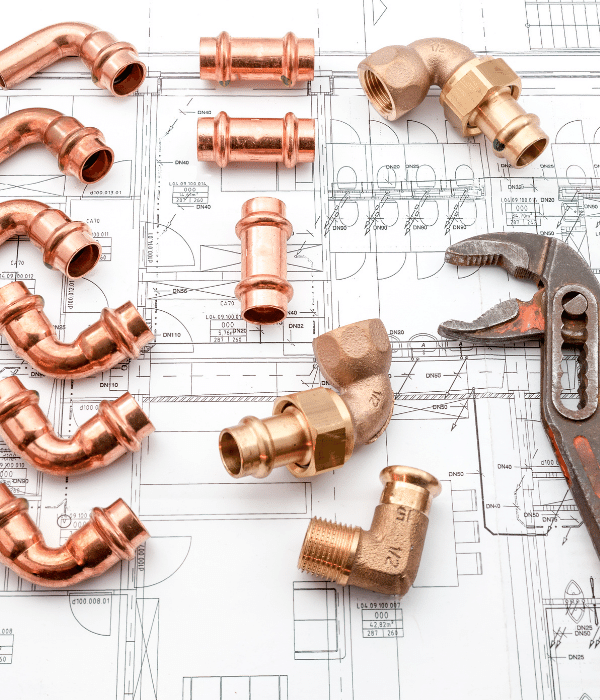

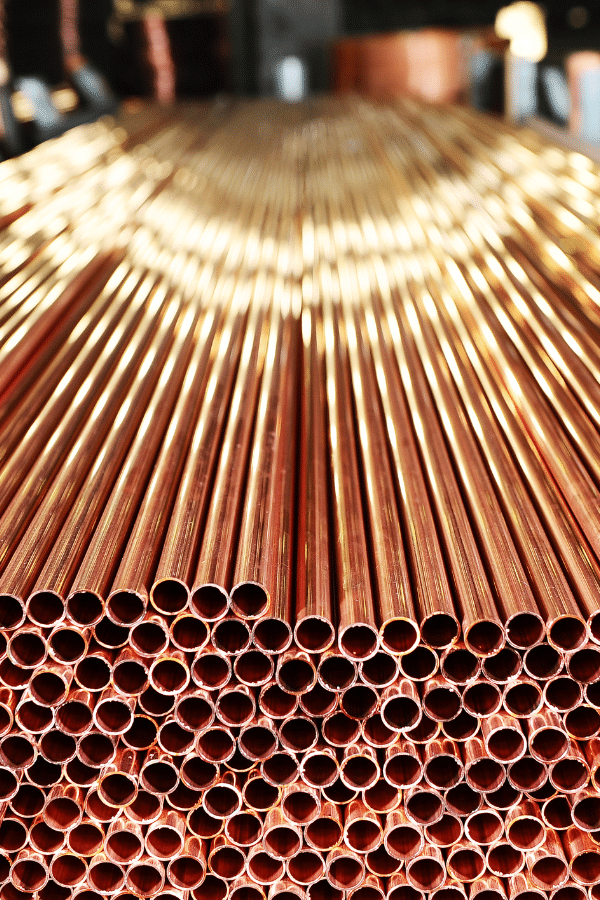

♦Copper CNC machining service is used for making different kinds of parts from Copper material such as Copper tube, Copper pipe, Copper sheet, Copper bar and other complex shapes that can be made by our experienced engineers. We can provide you with a wide range of processing capabilities to meet your requirements. We offer a complete range of machining services including: turning, drilling, milling, grinding and polishing etc. With our advanced equipment and dedicated team of professionals we can fulfill all your requirements professionally within the given time frame.

Why Choose Copper CNC Machining at ETCN

ETCN is a professional Copper CNC Machining service company in China. We can offer you the best quality machining services at competitive price.

♦1. Quality: Our strict quality inspection system ensures that each product is at its best condition before shipment.

♦2. Service: We provide the most comprehensive service including one-stop sourcing, design assistance, and flexible payment terms.

♦3. Quick Delivery: We have rich experience in producing high-quality parts on time and according to customers’ requirements.

♦4. Reasonable Price: We can provide you with high quality products at competitive prices based on our knowledge and experience of working with international customers.

Copper in CNC Machining – Copper Properties and Benefits

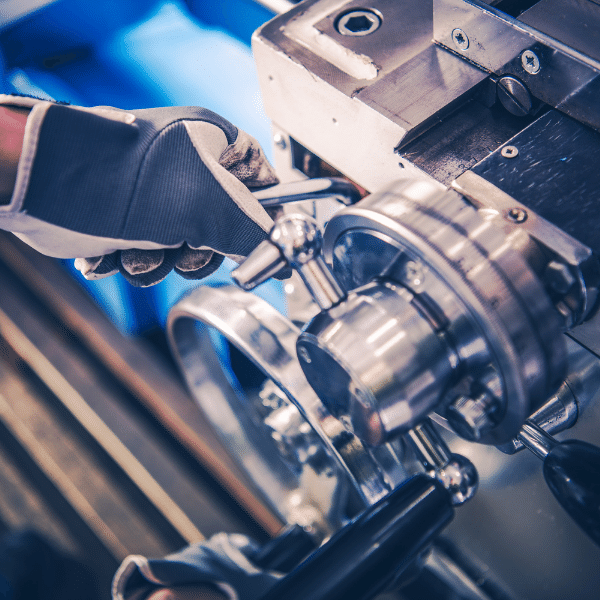

Copper is a soft metal with a low melting point, so it can be easily machined. Copper CNC machining is a process of manufacturing parts from a block of copper by using computer numerical control (CNC) technology.

Copper CNC machining is the best way to create intricate designs and shapes with the use of computer-controlled machine tools. It is also known as CNC milling or CNC turning. The process involves the use of numerically controlled (NC) machines to cut, drill, and shape parts from blocks of copper, brass or similar material.

The benefits of using this method are:

♦Lower cost – as compared to other materials such as steel, aluminum or plastic;

♦Better aesthetics – as it appears more aesthetically pleasing than other materials;

♦High strength – compared to other materials like aluminum but less than steel;

♦High conductivity – making it ideal for electrical applications like transformers;

♦Durability – providing strength while maintaining flexibility over time;

Custom Copper Parts

We are a professional custom copper parts manufacturer, with years of experience in this field. We have gained good reputation from our clients all around the world, especially in Europe and America.

We have strict quality control system and professional designers to develop new items according to your request. And our products are also exported to many countries such as Australia, United States, Canada and so on.

The key points of our company:

♦1. Small quantity is acceptable;

♦2. Quick delivery time;

♦3. Low price with high quality;

♦4. Customized design is welcomed;

♦5. Professional designer team to design according to customer’s request;

copper machining services

The machining of copper is similar to the machining of other metals, but there are some key differences. Copper has good thermal conductivity, so it can be cooled effectively when machining with water or oil coolants. Copper also has good electrical conductivity, which makes it easy to use electricity to perform many types of machining operations.

Copper machining services include:

♦Copper drilling services

♦Copper wire EDM (electrical discharge machine) services

Types of Copper Alloys in CNC Machining

The most commonly used copper alloys in CNC machining are the following:

♦ C10200 – This is a Cu-Ni-Co alloy that is used in the making of dies and punches.

♦ C10300 – This is a Cu-Ni alloy (copper nickel) that is used in the making of dies and punches. It has good strength, hardness, ductility and toughness.

♦ C11000 – This is a Cu-Ni-Fe alloy (copper nickel iron) that is used in the making of pump shafts and impellers, valve bodies, valve stems, metal seals and gaskets.

♦ A7000 – This type of copper alloy is primarily used as an electrical conductor because of its high conductivity. It also has good thermal conductivity which makes it ideal for heat sinks or other applications where heat must be dissipated quickly. It can be machined using standard methods like turning, milling or tapping since it doesn’t require any special treatments prior to machining operations.

♦ B70400 – This type of copper alloy has high strength at elevated temperatures which makes it ideal for applications such as aircraft components where high temperatures are common. It also has good tensile yield strength which makes it suitable for use as springs

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.