Finding a good CNC machining supplier in China is no easy task, especially when you’re just getting started or your requirements are vague. In this article, I’ll provide some context and help you understand why finding a good CNC machining company can help you succeed in business.

Analyze the CNC machining market

The CNC machining market is an emerging market with a high growth rate. The increasing demand for customized products and the increasing demand for high-end products is expected to drive the growth of this market. However, the increase in the cost of raw materials would hinder the growth of this market.

Analyze the CNC machining market; this report provides a detailed analysis of various factors that affect the growth of the CNC machining markets, such as drivers, restraints, opportunities, and challenges. This report also estimates the market size in terms of value (US$) and volume (K Units). In addition, it highlights key trends, drivers, and challenges prevailing in this market and forecasts its potential future growth prospects across different countries and regions.

The report further identifies key companies operating in this market and their sales performance for 2016-2020. It also highlights major technologies adopted by them which have helped them to increase their revenue generation capacity during the forecast period. The report analyzes various attributes of these companies, such as business overview, financial overview, business strategies adopted by them, and their recent developments in research & development activities.

Select qualified machining suppliers based on certain condition

At present, there are many companies in the market that provide machining services. Therefore, before you choose a supplier to do your machining work, you should consider several factors. A qualified supplier will help you save time and money.

The following are some of the factors that you should consider

Experienced and skilled engineers

The engineers at a good machine shop have worked together and developed an excellent team spirit. They have experience in different machining processes, better vice for customers. In addition, customer service improves your product design to achieve better results when mass production begins.

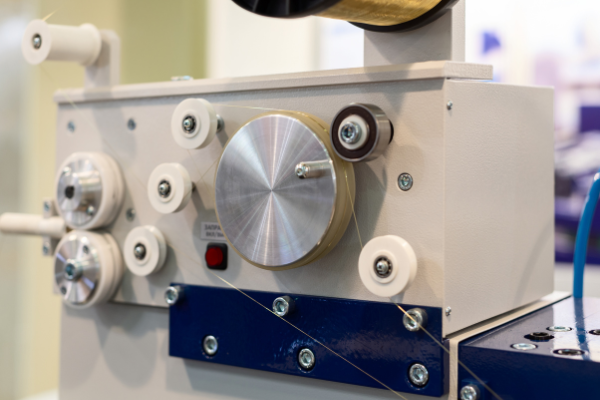

High-quality machines

Machi High-quality most important equipment in a good machine shop. If the machines are not up to standard or cannot meet your needs, then it will be impossible for them to do high-quality work for you. Therefore, before choosing a machine shop, ensure they have hiensurehines and advanced technology to do their jobs early and quickly.

Technical skills

When looking for a machine shop, ensure they have the right technical skills to do the job. It is important that they know how to use their machines and other equipment properly so that they can achieve this you are not sure about the technical skills of a machine shop, then it is best to ask for references from past customers. You can also visit their facility and check out how they work to ensure they can ensure they integrity and honesty

When you are looking for a machine shop, make sure that they have integrity and honesty. It is important to work with people who can be trusted so that your project will not be compromised.

Price and availability

It is also important to consider the price of your machine shop and whether or not they have the equipment you need. If you are looking for a business that can give you a discount on their services, then it is best to find one beforehand.

Field visit to machining suppliers

Visiting a machining supplier is a great way to get a feel for the industry and learn about the machines and processes used. If you’re planning on purchasing machining equipment, visiting suppliers is an important step in the buying process.

The following are some of the reasons why visiting suppliers is so beneficial:

Field Visits Help You Learn About Machining Equipment

Visiting a machine shop or other machining supplier can help you learn about different machines and processes used in their manufacturing operations. It’s also an opportunity to see if these suppliers are offering any products or services that meet your needs.

Field Visits Help You Identify Potential Partners

When visiting a supplier, it’s important to keep an open mind and not be afraid to ask questions. By doing so, you’ll be able to identify potential partners who can provide high-quality products or services at competitive prices.

Conclusion

To learn to source a good supplier, you must move beyond simply looking at price. You’ll also have to account for quality, project lead time, and service, and perhaps even search for the supplier’s reputation in the industry. The best way to do this is to look at all the suppliers you’ve received bids from and begin a quality check. Decide how much is too much for you to pay, and develop a checklist of features your new supplier will need to meet.