It is a topic you may not have thought much about, but determining surface roughness is important. You see, dozens of factors affecting your product’s service life can be influenced by surface roughness. The only real way to know what those factors are, and improve your surface roughness, is to know what they are. Today we’re going to look at some of them.

What is Surface Roughness?

Surface roughness is a physical attribute of a surface that describes the measurement and distribution of peaks and valleys on a surface.

The surface roughness is usually measured in micro-inches (μin) or micrometers (μm). This can be defined as the average distance from a peak to the next peak, not including the valley between them.

Surface roughness can be measured by an optical microscope, which uses light to assess irregularities in the surface. The principle behind this method is that light reflects off flat surfaces, but it scatters off uneven ones.

When a material is ground down and polished, it becomes smoother but rougher due to microscopic peaks and valleys on its surface. These are referred to as asperities, with high local stress or concentration stresses concerning the surrounding area. This can cause friction when two objects slide against each other because they are rubbing up against these asperities during contact.

The Factors Affecting Surface Roughness

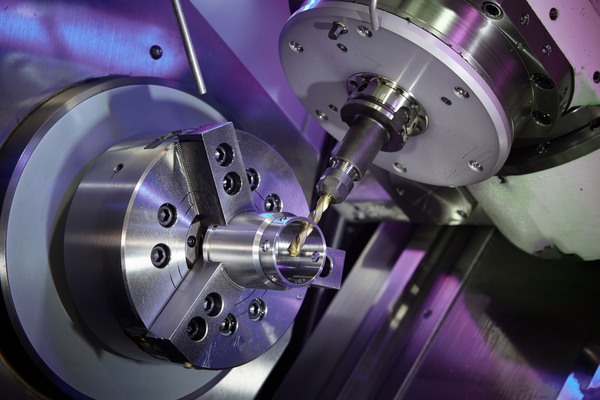

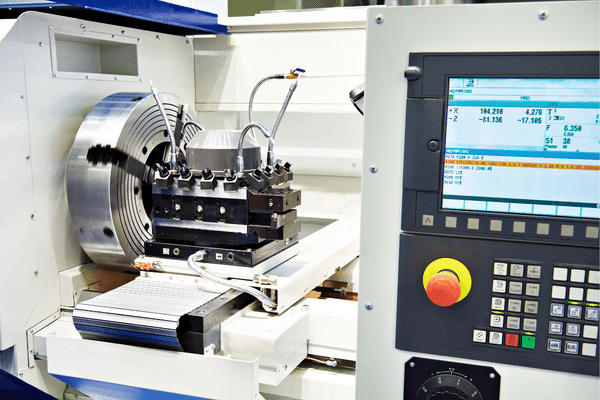

Cutting tools

The type of cutting tool you use will affect your finish quality. A dull tool will produce a rougher finish than one that is sharp. Also, the shape of your cutting tool will affect how much material it removes from the workpiece at each pass; a chamfer mill produces less material removal than a ball nose endmill.

Material properties and conditions

The material itself also has an impact on how smooth or rough your finished product will be. Plastic tends to be very smooth because it does not burnish (smooth out) like metal when machined with high speeds and feeds. Metal chips more easily than plastic chips when machined with high speeds and feeds, so you might need to use higher speed settings than normal to reduce chip build-up or buy smaller diameter endmills (to reduce feed rate).

Material Properties

The hardness and elastic modulus of the material greatly impact its ability to resist wear. The harder the material, the rougher it will tend to be. Materials like steel are generally harder than plastic, meaning they have higher surface roughness values when measured under similar conditions.

Tool Material and Condition

Different tool materials have different hardness levels, affecting their ability to cut through different materials with minimal damage or wear. When cutting soft materials like aluminum alloys, carbide tools are commonly used because they have high hardness values compared to other tools such as tungsten carbide or cemented carbide tools (which tend to be harder). The condition of these tools also affects their performance: if they become dull due to excessive use or improper maintenance procedures, they will not perform.

Cutting Speed

The speed at which you cut also affects your finish quality. If you cut too fast, heat will build up in your workpiece and cause stress fractures in your part’s surface finish; if you cut too slow or use too much force, small burrs may form around the edges of your part. Using proper cutting speeds for each material type will help prevent these issues from occurring during machining.

Processing technique

Different processing techniques produce different types of surface finish. For example, milling creates grooves on a material’s surface, whereas grinding removes material from its surface but leaves behind grooves instead of pits. And polishing produces flat areas but may leave behind fine scratches called scratch marks.

How to Improve Surface Roughness?

One way to improve surface roughness is by adding additional grinding steps in the manufacturing process. Grinding is sanding with abrasives much larger than those used in sandpaper or other abrasive tools. For example, if you want to grind a piece of metal down to very fine tolerances, you might not have to do much more than run it through an ultra-high-speed grinder with diamond particles. However, suppose you want a smooth finish on something like a car body panel. In that case, this method might not be effective because you would have to use very small pieces of diamond dust that wouldn’t provide enough material for smoothing out large areas.

Another way manufacturers can improve surface roughness is by using better quality materials during manufacture. For example, if you’re making an aluminum part whose surface needs to be as smooth as possible during assembly, you would use high-quality aluminum free of impurities. If the part is painted, you can take a similar approach by using high-quality paint materials that provide a smooth surface for your application.

Conclusion

A rough surface reduces the quality of a part in many ways. Surface roughness is controlled during milling by using the proper cutting tools and maintaining them properly. Although surface roughness will never produce a perfect surface, it can be improved. All that is needed is a simple understanding of the causes of surface roughness and how this roughness can be measured. Then, small changes can be made to ensure that parts are within specification and have an acceptable level of surface roughness.