If you are looking for CNC machining services, then China is the place to be. With a massive manufacturing industry and an abundance of skilled workers, China offers some of the best CNC machining services in the world. This article will examine what sets Chinese CNC machining services apart and how you can find the right provider for your needs. So, whether you are a small business looking for affordable production or a large corporation needing high-volume output, read on to learn more about why China should be your go-to destination for CNC machining services.

CNC Machining Explained: Why China Is the Best Place for CNC Manufacturing Services

When it comes to manufacturing, many factors go into choosing the best process for your project. With so many options on the table, it can be tough to decide which one is right for you. In this blog post, we will break down CNC machining and explain why it’s the best option for buyers looking for manufacturing services in China.

What Is CNC Machining?

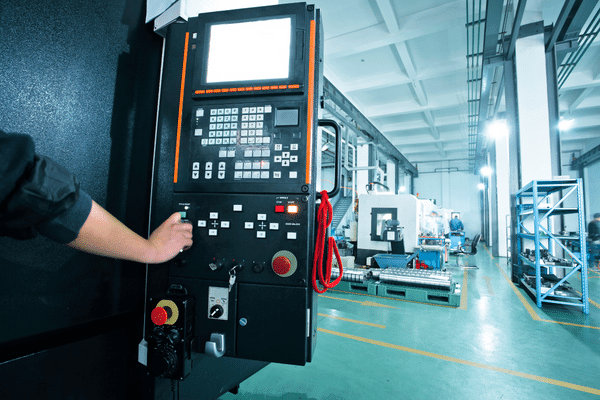

CNC machining is a manufacturing process that uses computer-controlled devices to cut and shape the material. Unlike traditional machining methods, CNC machining offers greater precision and repeatability thanks to its computer-aided operation. This means that parts produced via CNC machining will be more consistent and have tighter tolerances than those produced with other methods.

Benefits of CNC Machining Over Other Manufacturing Processes

There are several reasons why CNC machining is the best option for many buyers. In addition to its precision and repeatability, CNC machining is relatively fast and versatile. It can be used to produce parts from a wide range of materials, including metals, plastics, and composites. And because it doesn’t require expensive tooling like some other manufacturing processes, it’s often more cost-effective.

Why China Is the Best Place for CNC Machining Services

If you’re looking for high-quality CNC machining services, there’s no better place to look than China. That’s because China has the world’s largest manufacturing base, which gives buyers access to an unparalleled pool of talented and experienced manufacturers. Additionally, Chinese manufacturers can offer competitive prices thanks to their low labor costs and economies of scale.

Conclusion:

Whether you’re looking for precision, repeatability, or cost-effectiveness, CNC machining is a clear choice. And when it comes to finding the best CNC manufacturers in the world, there’s no better place to look than China. With its massive manufacturing base and competitive pricing structure, China is the perfect place to get your CNC machined parts made.

A guide to pricing for CNC machining services in China

CNC machining is a popular manufacturing process in China used to create precision metal parts. The process involves using computer-controlled machines to remove material from a workpiece to create the desired shape. Due to the high level of accuracy and repeatability, CNC machining is well suited for small batch and mass production runs. In this blog post, we will guide you through the different pricing models for CNC machining services in China so that you can make an informed decision when selecting a supplier.

Pricing Models for CNC Machining Services in China

There are three main pricing models for CNC machining services in China: cost per piece, cost per hour, and flat rate.

Cost per piece is the most common pricing model and is calculated by multiplying the number of pieces produced by the unit cost. The unit cost includes materials, labor, machine time, setup time, and packaging. This pricing model is suitable for buyers who have stable order volumes.

Cost per hour is calculated by multiplying the hours required to complete the job by the hourly rate. The hourly rate includes the costs of labor, machine time, and setup time. This pricing model suits buyers who need quick turnaround times or have small batch orders with variable order volumes.

A flat rate is a single price charged for the entire job regardless of quantity or job size. This pricing model is suitable for buyers who have large batch orders with stable order volumes.

Conclusion:

When choosing a CNC machining supplier in China, it is important to understand the different pricing models to select the one that best suits your needs. If you have any questions about pricing or would like help finding a supplier, please contact us, and we will be happy to assist you.

A Brief History of CNC Machining

When one thinks of manufacturing, it’s easy to imagine large factories with billowing smokestacks and lines of workers performing repetitive tasks day in and day out. But that’s not the whole story. Modern manufacturing is a highly automated process that relies heavily on computer-controlled machines, often called CNC (computer numerical control) machines. In this blog post, we’ll take a brief look at the history of CNC machining and how it has developed over the years.

CNC machining is a manufacturing process that involves using computers to control the movement of tools. This process can be used to create intricate parts for everything from airplanes to medical devices. The first CNC machine was created in the 1950s and was used to create stereo lithography models; however, it wasn’t until the 1970s that CNC machines began to be used extensively in manufacturing.

Since then, CNC machining has undergone continual refinement as technology has advanced. Today’s CNC machines are faster and more precise than ever, creating parts with stunning accuracy and detail. And as artificial intelligence continues to develop, CNC machines will likely only become more sophisticated in the future.

CNC machining is a vital part of modern manufacturing, capable of creating parts for various applications with speed and precision. This technology has come a long way since its inception in the 1950s, and there’s no doubt that it will continue to evolve in the years ahead. If you need high-quality CNC machined parts, we hope you’ll trust us here at ETCN Manufacturing Co., Ltd.—we’re your one-stop shop for all your CNC machining needs!

The Different Types of CNC Machines Available on the Market Today

Blog Introduction: With the rise of advanced manufacturing technologies, the need for CNC machines has increased exponentially in recent years. If you are in the market for a CNC machine, it is important to know the available types to make an informed decision. This blog post will provide an overview of the different types of CNC machines available on the market today.

The three main CNC machines are milling machines, lathes, and machining centers.

Milling machines are used to create parts with complex shapes and features. These parts can be made from various materials, including metals, plastics, and composites. Milling machines can be either horizontal or vertical.

Lathes create symmetrical parts such as shafts, spindles, and nuts. Lathes can also be used to create threads and other textured surfaces.

Machining centers are versatile machines used for various operations, including milling, drilling, and tapping. Machining centers typically have multiple axes that allow them to create parts with complex geometries.

Conclusion:

There are a wide variety of CNC machines available on the market today. When choosing a machine for your applications, it is important to consider the type of machine, the material you will be machining, and the complexity of the parts you need to produce. If you have any questions about finding the right CNC machine for your needs, please contact us, and we will be happy to help.

How to choose a reputable CNC machining services supplier in China

Blog Introduction: If you are in the market for CNC machining services, you may have considered using a supplier based in China. After all, China is well-known for being a leading manufacturing hub with many suppliers. However, it’s important to know that not all Chinese suppliers are created equal. This blog post will provide tips on choosing a reputable CNC machining services supplier in China.

- Do your research: When looking for a CNC machining services supplier in China, it is important to do your research and ask around for recommendations. A good start is to search online for forums and discussion groups related to your industry. Here, you can get first-hand insights from other buyers who have used CNC machining services in China and can offer guidance on which suppliers are reputable and which ones should be avoided.

- Check credentials: Once you have compiled a list of potential suppliers, the next step is to check their credentials. A reputable supplier should have a good track record and should be able to provide references from past clients. It is also worth checking whether the supplier is a member of any trade associations or has been certified by any third-party organizations. These memberships and certifications can give you peace of mind that the supplier is reputable and ships high-quality products.

- Inspect the facility: Once you have narrowed down your list of potential suppliers, arrange for visits to their facilities. This will allow you to see firsthand what operation they are running and whether they have the necessary equipment and expertise to meet your CNC machining needs. During your visits, pay close attention to cleanliness, safety standards, and employee training. All of these factors can impact the quality of the finished product.

Conclusion:

Choosing a reputable CNC machining services supplier in China doesn’t have to be difficult if you know what to look for. By following the tips outlined in this blog post, you can ensure that you select a supplier that will meet your needs and deliver high-quality products.

How to Get the Most Out of Your CNC Machining Services Supplier in China

Regarding CNC machining services, China is one of the world’s leading suppliers. To get the most out of your supplier, however, it’s important to keep a few things in mind. Here are some tips for getting the best possible service and products from your CNC machining services supplier in China.

- Define Your Needs Clearly

Before you even start looking for a CNC machining services supplier in China, it’s essential that you take the time to define your needs clearly. What kind of parts or products do you need? What are your tolerances? What is your budget? Once you understand your needs well, you’ll be in a much better position to find a supplier that can meet them. - Do Your Research

The next step is to research and find a few reputable CNC machining services suppliers in China that you can compare. When you’re looking at different suppliers, be sure to compare their prices, capabilities, and customer reviews. This will help you narrow down your options and choose the best possible supplier for your needs. - Negotiate Prices and Terms

Once you’ve found a few potential suppliers, it’s time to start negotiating prices and terms. In general, you’ll find that Chinese suppliers are very willing to negotiate on both price and terms. If you’re unhappy with the initial quote, don’t be afraid to counteroffer. The goal is to get the best possible price without sacrificing quality or service.

Conclusion:

By following these tips, you’ll be well on your way to getting the most out of your CNC machining services supplier in China. Remember, take the time to define your needs clearly, do your research, and don’t be afraid to negotiate on price and terms. By taking these steps, you’ll ensure you get high-quality parts or products at a fair price.