If you’re looking for great material for turning purposes, consider PTFE. This fluorocarbon-based polymer is non-stick, chemically inert, and offers reduced friction. This material is perfect for various applications, and machining it on a lathe will make it easier to make durable and wear-resistant parts.

PTFE is a fluorocarbon-based polymer

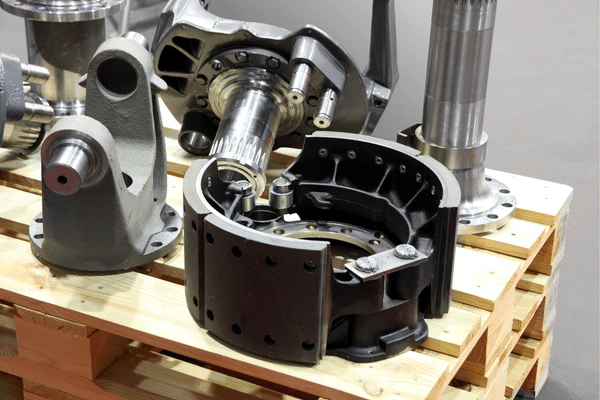

PTFE is a fluoro-carbon-based polymer used to make brake linings, hoses, and other components. It is resistant to high temperatures and is hydrophobic, making it useful for many industrial applications. PTFE is also used as a coating on non-stick cookware. Because of its hydrophobic nature, it repels water and has a high heat-resistance rating. It is also used in pyrotechnic compositions as an oxidizer, along with powdered metals and aluminum. When burnt, it produces metal fluoride and carbonaceous soot. PTFE and aluminum are also used in thermobaric fuel compositions and solid-fuel rocket propellants.

Due to its softness, PTFE is easy to machine. However, this material has a high coefficient of expansion, which makes it prone to creep and cold flow. Due to these properties, machining parts made of PTFE may not be suitable for tight tolerances. This means proper annealing and machining techniques are needed to ensure quality parts.

The material is made from carbon and fluorine molecules and has a high molecular weight. The fluorine is bonded to the carbon atoms in the polymer, which gives it chemical inertness. The chemical inertness of PTFE is explained by the shielding effect of the fluorine atoms on carbon atoms. Despite this, PTFE is not completely insoluble and is also very reactive. It can be attacked by alkali metals, which will remove the fluorine and damage the molecule. Printed circuit boards, hookup wire, and more can be made of PTFE.

PTFE is widely used in manufacturing fiberglass and carbon fiber composites. It is used as a barrier material between the part and non-production materials. Fiberglass and carbon fiber plies are very sticky and may cause PTFE to stick to the part.

It is chemically inert.

PTFE, also known as Teflon, is a chemically inert material that is resistant to heat and chemicals. It can be machined to a variety of sizes and gauges, and can be used in a variety of applications. PTFE can be used to make gaskets and rings, and is available in 0.010-inch to 0.25-inch thickness.

PTFE is a fluoropolymer with high chemical and thermal resistance. It is non-stick and has a high melting point. It also exhibits excellent insulating and electrical properties. It is widely used in a wide range of industries, from the aerospace industry to the music industry. It is chemically inert, non-toxic, and non-oxidizing, and is resistant to most solvents.

The PTFE material can be easily machined on a lathe. It is available in many colors and can be shaped and cut to fit into any part. This material is extremely resistant to heat and chemicals, making it ideal for machining parts for various industries. In addition to machining parts, PTFE is also useful in coatings.

It has low friction

PTFE, otherwise known as Teflon, is a slippery plastic that is a good material for low-friction parts. It also is a good insulator and is resistant to high temperatures and chemicals. Its many applications range from non-stick coatings for kitchen pans to high-tech medical devices. These include medical implants, surgical instruments, and test equipment.

The low-friction properties of PTFE enable the material to be machined on a lathe with high precision. It is a great material for low-friction machining and is commonly found in many types of parts. It also has a high chemical resistance and the lowest coefficient of friction of any solid material. It is widely used in manufacturing mechanical equipment and valves, but it is also used in many other industries.

Low-friction slideways are a great way to reduce static friction. They also eliminate stick-slip and offer uniform motion even at low speeds. In addition, low-friction slideways are more rigid than those made from cast iron. This allows them to last much longer than cast iron and other metals.

One of the biggest challenges of machining PTFE is that parts made of this material are large in diameter and cannot be cooled while turning. This makes inspection of the resulting parts difficult. However, an experienced machinist knows how to adjust the part properly.

It is non-stick

Teflon (or PTFE) is plastic with non-stick properties and is designed for use in extreme temperatures. Its low coefficient of friction makes it useful for various industrial applications. Regarding machining, PTFE is very versatile and can be shaped to any desired shape. At Brogan & Patrick, we offer services in machining PTFE to meet your needs.

PTFE can be easily machined using a conventional lathe. The material is characterized by its low friction and chemical resistance, making it an ideal material for a wide range of applications. These applications include semiconductor, mechanical, and seal applications. This makes machining Ptfe parts a popular process in many industries.

PTFE, also known as Teflon, is a versatile material resistant to high temperatures and many chemicals. It’s also an excellent insulator. Because of these properties, PTFE is used in various products, from non-stick kitchenware to high-tech medical applications. For example, PTFE is used in implants, surgical instruments, and test equipment.

It is non-flammable

PTFE is a non-flammable material that is highly heat resistant and resists friction against solids. It is also non-reactive and anti-corrosive. It is used in the aerospace industry as a lubricant for valves and other components. It is also used in food processing.

PTFE, also called Teflon, is a fluoropolymer that has unique properties. It is non-flammable and non-reactive and highly resistant to heat, chemicals, and oxidation. It is a highly versatile material that has a wide range of applications. Besides industrial and consumer products, it is used for coatings and semiconductors. It is also used as an inert ingredient in pesticides and other chemicals.

PTFE, or Teflon, is a semi-crystalline plastic that is a great choice for low-friction parts. Because of its chemical and heat resistance, it’s an excellent insulator. It can be machined into numerous shapes, including deep pockets with small radii. It can be used for all precision applications, from high-tech medical devices to kitchenware.

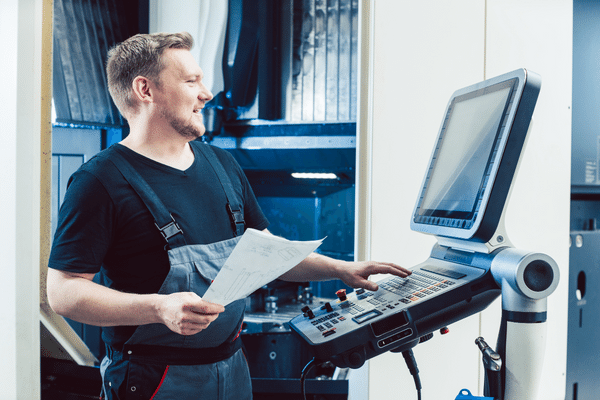

PTFE can be machined in a variety of ways. Depending on the desired outcome, it can be custom manufactured or processed by high-speed 2-axis CNC turning. PTFE can also be reinforced with other materials, such as silica or glass microsphere. Additionally, PTFE can be produced in large production runs and is FDA-approved.

It is non-adhesive

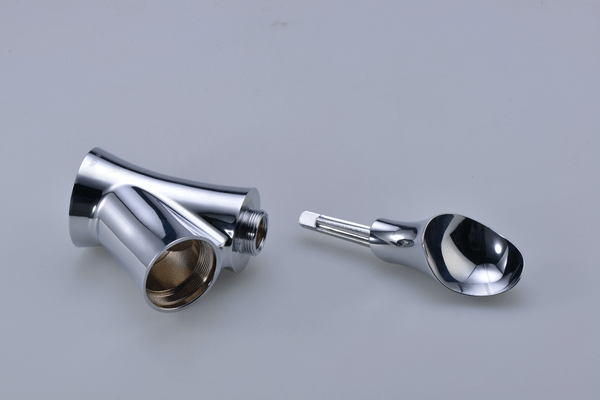

Polytetrafluoroethylene (PTFE) is an engineering plastic with excellent properties and can be used in a wide range of applications. This soft and non-adhesive material resists high temperatures, chemicals, and abrasion. It is also a great insulator and is used in a variety of everyday products. Its properties make it a popular choice for machining parts in a number of industries. Applications for PTFE machined parts include mechanical and semiconductor equipment, seals, valves, and more.

When it comes to machining PTFE, the process is very similar to machining other materials. However, some PTFE parts may require a different material or technique, particularly if the part requires tight tolerances. Another challenge with machining PTFE is that the material can lose shape when under high pressure. This is a problem when machining it for mechanical joints or moving components. In addition, plastics have a lower tolerance for finishing than metals, so you may want to work with a manufacturer who is experienced in machining PTFE.

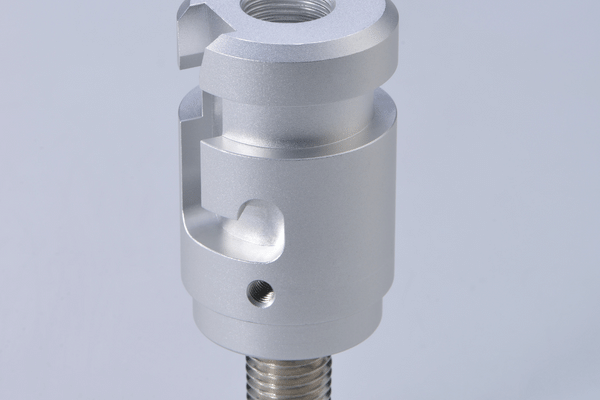

Machining PTFE on a lathe requires a great deal of precision and intricacy. Depending on the type of machining, the PTFE material can be used to create products with complex geometries. This type of product can be used up to 150degC. Hot-coining PTFE products also have an advantage: they return to their original shape when reheated.