Aluminum die casting is the most common process used for manufacturing various components. It is cost-effective, fast, and flexible. Also, aluminum has high corrosion resistance and good thermal conductivity.

This guide will help you understand how to use aluminum for die-casting applications, including how to design parts for aluminum die-casting.

Brief Overview of Aluminum Die Casting

Aluminum die casting is the most widely used casting process in the world. It is inexpensive and can produce many products, from small, simple parts to large, complex assemblies.

Aluminum die casting has been around for over 100 years and is still the most widely used casting process today. With its ability to make various parts with high-quality finishes and low production costs, aluminum dies castings have become an integral part of many industries, including automotive and aerospace.

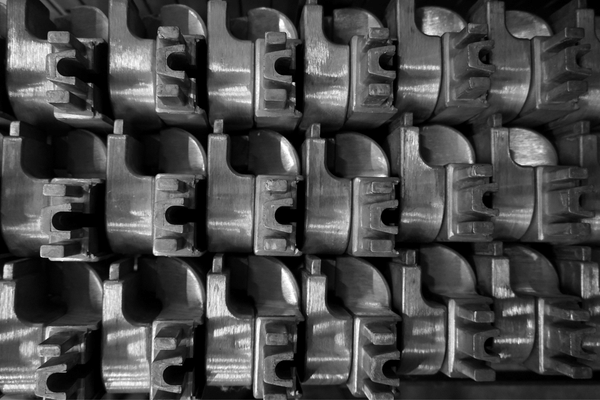

The bare aluminum die-casting process involves pouring molten aluminum into a cavity (known as a die) made from sand molds or permanent tooling. The molten metal is then cooled and ejected from the mold forming the desired part shape. The aluminum dies castings are then cleaned, inspected, and ready for machining or assembly with other components.

The following are the benefits of aluminum die casting;

Aluminum dies casting is a process that has been used for many years and is still the preferred choice for many industries. It has many advantages which make it the most popular choice.

Aluminum dies casting is a process that has been used for many years and is still the preferred choice for many industries. It has many advantages which make it the most popular choice.

10 Benefits of Aluminum Die Casting:

Good mechanical properties

Aluminum alloy has good mechanical properties such as high strength, rigidity, durability, plasticity, and resilience.

High melting point

Aluminum alloy has a high melting point (above 420°C). Therefore, it can be processed by hot working or extrusion methods to obtain complex shapes with high strength at high temperatures.

Lightweight

Aluminum alloy is light but has good strength and rigidity at room temperature. It can be used in civil engineering structures such as buildings and bridges or vehicles like airplanes and ships.

Corrosion resistance

Aluminum alloys have excellent corrosion resistance, making them suitable for use in saltwater environments such as marine applications such as boats and ships where steel cannot withstand the saltwater environment without being protected with an anti-corrosion coating.

Electrical conductivity

Aluminum alloys are good electrical conductors, making them suitable for electric motors, generators, and transformers.

Weight

Aluminum alloys are lightweight, making them suitable for applications where weight reduction is important, such as airplanes and rockets.

Thermal conductivity

Aluminum alloys are good thermal conductors, making them suitable for applications where heat transfer is important, such as engines and solar panels.

Strength

Aluminum alloys have a high strength-to-weight ratio, making them ideal for applications requiring high strength while minimizing weight, such as aircraft, rockets, and missiles.

Ductility

Aluminum alloys have high flexibility, making them suitable for applications where flexibility is important, such as wires, cables, and springs.

Importance of DFM of Aluminum Die Casting

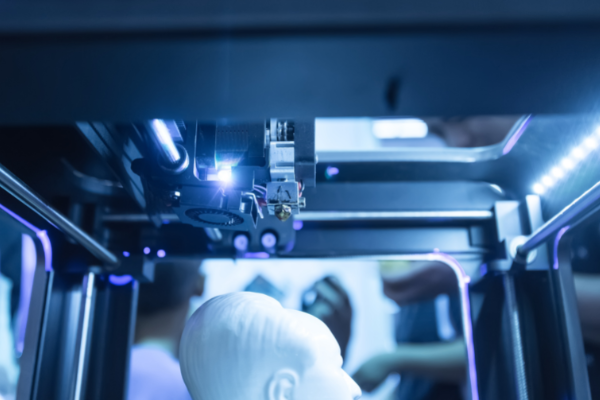

The DFM process is a set of techniques that help manufacturers to reduce the cost of design and manufacturing by improving the efficiency and quality of products. To get good results from DFM, it is important to understand the product design well.

Die-cast aluminum products are used in transportation, electrical equipment, and medical technology industries. To meet customers’ requirements and reduce product costs, it is necessary to optimize the design of die-cast aluminum products through DFM (Design For Manufacturing). This will help you save time and cost when making changes in the manufacturing process.

12 Tips for Producing Better Aluminum Castings

Aluminum has been used for years to produce large castings such as aircraft components and even entire aircraft frames, where weight savings are important. Here are 12 tips for producing better aluminum castings:

Use the right aluminum alloy.

The first thing you need to do when producing aluminum castings is to choose the right alloy for your needs. Aluminum alloys have different properties depending on their composition, which can affect the final product. For example, an alloy with high strength and corrosion resistance will be needed if you want to make an engine part. On the other hand, if you want to make something like a decorative object or sculpture, then an alloy with good workability will be necessary.

Avoid debris inclusions in your mold.

If casting a complicated part requires multiple molds, it’s important to avoid debris inclusions. These small bits of sand and other materials get trapped between the two halves of the mold and end up in your finished casting. This can cause defects such as porosity and voids, which can lead to poor-quality parts or even safety issues.

One way to avoid debris inclusions is to ensure both halves of the mold are properly cleaned before joining them together with putty or adhesive material. Also, ensure no residual residue is on either half of the mold after cleaning it since this can prevent them from sealing properly when assembled.

Make sure your pattern is properly prepared.

You may want to make a master pattern, which can then be used as a model for other patterns. Aluminum patterns must be made from aluminum or magnesium; these are the only materials that can withstand the high temperatures involved in the casting process. The pattern should be cleaned and dried before using it; oil or moisture can cause problems with the casting process.

Cast With a Cooling Schedule

Aluminum is a very reactive metal that must be cooled slowly to get good castings. The aluminum cooling schedule depends on the casting size, but it usually takes at least 20 minutes per inch of thickness. If this is your first time casting, it’s best to start with a small object and work to larger pieces. If your object is too large, it will be difficult to control its cooling rate and may crack or warp during cooling.

Avoid too many drafts.

Draft angles help the mold release from the casting and prevent air pockets from forming. If you have too many draft angles in your mold design, it can cause problems when casting because it restricts the flow of molten metal into certain areas of the mold cavity. This can result in poor surface finish or even incomplete mold cavity filling.

Undercuts are undercut areas that must be filled with molten metal during casting. While undercuts are unavoidable in certain parts of a design, they should be kept to a minimum if possible so as not to interfere with other features on your part.

Use an accurate parting line for gravity die casting.

Gravity dies castings inject molten metal into a mold cavity under high pressure. As the molten metal fills the mold cavity, it cools and solidifies into a single piece of metal with no seams or joints. An inaccurate parting line on your mold could lead to poor quality castings or even failure of the casting itself. Therefore, you must use an accurate parting line on your molds so that everything will be fine with poor-quality castings due to inaccuracies in their design.

Make sure your mold cavity is properly prepared.

A good mold should have a smooth surface with no pits or imperfections. To achieve this, you should use fine abrasive paper on all surfaces that will contact the molten metal. This will remove any scratches or roughness from previous castings and provide a smooth surface for the next casting.

Use proper pouring procedures.

Aluminum melts at around 1,200 degrees Fahrenheit (650 degrees Celsius). To keep the metal from overheating, use adequate ventilation and keep the furnace door closed during casting. Make sure you have a safety screen in place before melting any metal.

Maintain proper temperatures throughout the casting process. An electric furnace should take about 20 minutes to reach 1,200 degrees Fahrenheit (650 degrees Celsius).

Be aware that your temperatures will drop as soon as you pour into the mold. Keep an eye on your thermometer after each pour to ensure you don’t let it get too low — especially if you’re planning to pour it several times in a row.

Use a proper mold release agent.

Aluminum tends to stick to molds when it cools down, leading to cracking and other problems. A good mold release agent will help prevent this by lowering the surface tension of the metal so that it doesn’t stick as much to the mold. It also helps with ejection since it allows for easy separation between the two pieces from which your casting was made.

Check the surface finish on die castings.

The first thing to do is check the surface finish on your die castings. This will tell you what surface finish is possible with your production process. If you’re using an investment casting process and need to know how well-defined the casting surfaces are, send a sample of each part to an outside laboratory for metallographic analysis. This will give you an idea of how well-finished your parts are likely to be from one batch to another and whether there are any significant variations in grain size or structure. If these variables aren’t consistent, it’s not worth spending money on tooling improvements until they are more consistent.

correct surface preparation

You will often find that die-casting companies offer various surface finishes for their products. This is because some customers prefer a high-gloss finish while others prefer a matte. Knowing what finish you want before ordering any die castings is important, so do your research beforehand. Ask other businesses what they think about the quality of the surface finish on each type of product they’ve ordered from this company and whether there were any issues with it. You should also ask if other options are available if the one you choose isn’t right.

Check the dimensional accuracy of castings.

The dimensional accuracy of a casting refers to how closely the dimensions match those specified by the customer. This can be measured by comparing the actual dimension against the nominal dimension (the size specified by the customer). For example, if your customer requires a specific diameter of 1 inch, then any casting that measures between 0.99 and 1.01 inches will have good dimensional accuracy. It will have poor dimensional accuracy if it measures less than 0.99 or more than 1.01 inches.

Correct assembly

The first step in producing any cast component is correct assembly. This means ensuring that all components are assembled correctly and with sufficient surface contact to ensure good bonding with the parent metal. If there are gaps or poor contact between components, cracks may form in the casting and may be difficult to detect until after they have occurred. Improper assembly can also lead to porosity in the casting and other defects, such as blow holes and porosity in the finished part.

Conclusion

Aluminum die casting is an art, not a science, and every machining process requires a human decision. Sure, you can follow the guidelines, but this makes die-casting unique. The users must be familiar with the production philosophy, mold technology, and material characteristics to make the right choices while machining aluminum alloys to achieve maximum results.