Kern CNC Machines: Quality and Durability in One Package

If you’re looking for a top-quality CNC machine, you should seriously consider a Kern machine. Built to be reliable and efficient, Kern machines have been the industry leader since 1966. This blog post will discuss why Kern machines stand out from the competition and how they can help your business succeed.

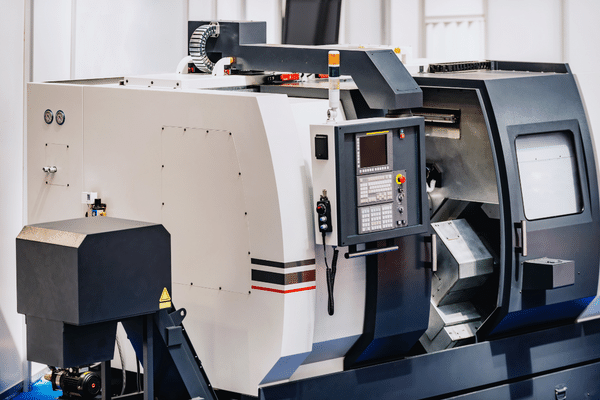

Kern CNC machines are made with quality components that ensure long-term durability. We use only the best materials available so that our machines stand up to the toughest conditions. And with a wide range of models, sizes, and features to choose from, you’re sure to find the perfect fit for your needs. Whether you need a small precision machine or something larger for mass production runs—we have an option that will meet your requirements.

Kern also offers exceptional customer service before and after purchase. Our knowledgeable staff is always happy to answer questions about our products or provide technical support when needed. We even offer free training sessions so new customers can quickly and safely familiarize themselves with their machines. Plus, we provide maintenance contracts and spare parts supplies as needed so you can keep your machine running smoothly for years to come.

Finally, Kern offers competitive pricing on all our machines, so you know you’re getting the best value for your money. With top-of-the-line quality at an unbeatable price, there’s no reason not to choose a Kern CNC machine for your business needs!

When it comes time to buy a CNC machine, make sure you turn to Kern first! With high-quality components, exceptional customer service, training options, and affordable pricing—there’s no better choice than Kern CNC machines for all of your machining needs. So don’t wait any longer; contact us today and find out why Kern has been the industry leader since 1966!

Why You Should Invest in a Kern CNC Machine

Are you looking to invest in a CNC machine? If so, then you should consider investing in a Kern CNC machine. Kern is an industry leader when it comes to the production of precision parts and components, and their machines are among the most reliable and efficient on the market. Here’s why you should strongly consider investing in a Kern CNC machine for your business.

High-Quality Parts and Components

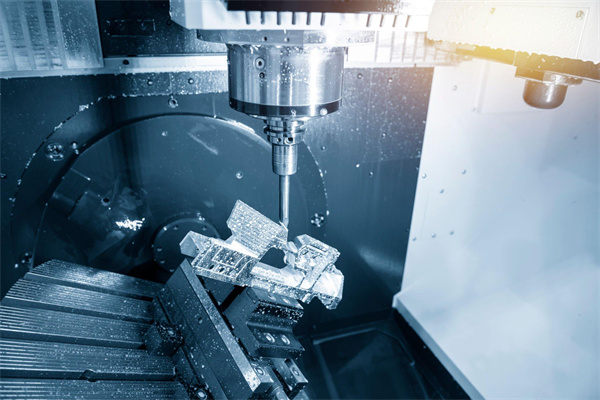

Kern machines are known for producing high-quality parts and components that can be used in a wide range of industries, from aerospace to automotive. Their machines use advanced technology such as laser cutting and CAD/CAM software to ensure accuracy and precision. This means that when you invest in one of their machines, you can be sure that it will produce parts that meet even the most stringent quality standards.

Cost-Effective

Kern’s CNC machines are also cost-effective, as they require minimal maintenance costs compared to other brands on the market. This means that you can save money over time by investing in one of their machines rather than having to replace or repair other machines more frequently. Furthermore, Kern offers financing options so that businesses of all sizes can still take advantage of the cost savings associated with purchasing one of their machines.

Easy to Use

Kern’s CNC machines are easy to use, making them ideal for beginners who may not have much experience operating complicated machinery. They come with user-friendly software that makes it easy to load programs into the machine and get started right away. Additionally, they offer free online support so customers can get help quickly if they have any questions about using their products.

Investing in a Kern CNC machine is an excellent choice for businesses looking for an efficient way to produce high-quality parts and components at a reasonable price point. Plus, their intuitive software makes it easy for users of all levels – from novice operators to experienced machinists – to quickly learn how to use their products effectively without sacrificing quality or precision.

Ultimately, purchasing one of Kern’s CNC machines is an investment worth making for any business serious about staying competitive in today’s market.

An Overview of Kern CNC Machines and Prices

Are you in the market for CNC machines? If so, you should consider Kern CNC as a potential supplier. Their product range offers a wide selection for every buyer’s needs and budget. In this blog post, we will cover the basics of Kern’s CNC machine products and prices so that you can make an informed decision when purchasing a CNC machine.

Kern’s Product Range

Kern’s range of CNC machines covers all industrial applications, including metals, plastics, woodworking, milling, drilling, routing, and engraving. They also provide turnkey solutions with their advanced automation systems to maximize production efficiency. All of their products are designed to meet the highest quality standards and offer superior performance at competitive prices.

Kern’s Prices

Kern offers several pricing options to accommodate different budgets. Their basic machines start at around $20,000 USD, while more advanced models can cost upwards of $100k USD. They also offer flexible financing options to help spread out payments over time. Additionally, they have service contracts available for maintenance and repair services that help keep your machine running smoothly.

Kern also provides training courses for new customers who need assistance in setting up and operating their machines properly. This ensures that buyers get the most out of their purchase and helps them understand how to use their new machine effectively to optimize productivity and cut costs over time.

In conclusion, Kern is an excellent choice when it comes to buying a CNC machine due to its wide product range and competitive prices. With flexible payment options, comprehensive service contracts, and comprehensive training programs available, buyers are sure to get the best value from their purchase from Kern CNC Solutions. Whether you’re looking for a basic or advanced machine for your industrial application needs, Kern has something for everyone at an affordable price point. With Kern as your partner in innovation and productivity improvements on-site – there’s a no better option than Kern!

How to Select the Right Kern CNC Machine for Your Business or Project

If you are looking for a quality CNC machine, Kern CNC machines are some of the best in the business. But with a wide range of models available, how do you know which one is right for your needs? This blog post will provide an overview of the different types of Kern CNC machines and some tips on choosing a model that is ideal for you.

How to Choose a Kern CNC Machine

The first step in selecting the right Kern CNC machine for your business or project is to consider the type of work you plan to undertake. Do you need a milling machine or lathe? Will you be cutting wood, metal, plastic, or other materials? Once you have answered these questions, you can narrow down your choice to specific models within each category.

Kern offers vertical and horizontal milling machines, lathes, and 3-axis machining centers. Each type of machine has its features and benefits that should be considered when selecting. For example, vertical milling machines tend to be more compact and require less space than their horizontal counterparts. On the other hand, horizontal milling machines offer greater flexibility in terms of material size and shape. Lathes are ideal for turning complex shapes, while 3-axis machining centers can perform multiple operations simultaneously with greater accuracy and speed than other types of machines.

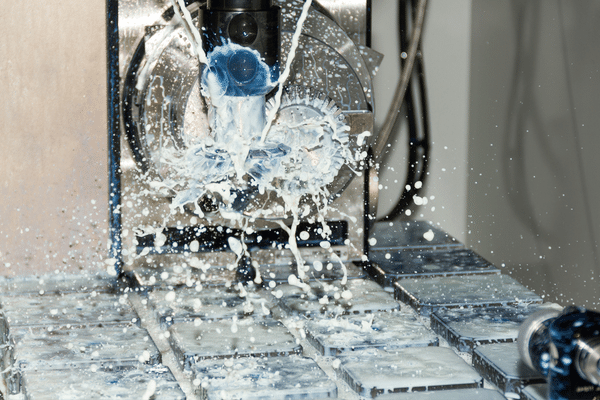

In addition to considering the type of work you will be doing with your Kern CNC machine, it is also important to take into account power requirements. Some models come equipped with an integrated motor, while others require an external power source such as an electric motor or compressed air line. You should also determine whether you need manual or automated loading/unloading capabilities and additional features such as coolant systems or spindle speed control options.

Choosing the right Kern CNC machine for your business or project can seem daunting at first, but it doesn’t have to be! By understanding which type of machine is best suited for your needs (lathe vs. milling machine), considering what materials you plan on working with (wood vs. plastic vs. metal), and assessing any additional features (coolant systems, etc.), you can make an informed decision that will serve your long-term needs without breaking the bank! With this knowledge, all left is to purchase a high-quality Kern CNC machine that works perfectly for your business or project!

Maximizing Your Kern CNC Machine Investment

Investing in a Kern CNC machine is a major decision for any business. Not only does it require large capital investments, but it also requires an understanding of how to get the most value out of the machine. In order to maximize your investment, you need to be aware of the best practices for using and maintaining your Kern CNC machine.

Maximizing Your Efficiency with Your Kern CNC Machine

The efficiency of your Kern CNC machine depends on how well you use the machine. The main way to maximize efficiency is through proper setup and programming techniques. Setting up your Kern CNC machine correctly can save you time, money, and effort in the long run by avoiding costly errors. Also, proper programming techniques help ensure your project runs as quickly and accurately as possible. Proper maintenance helps keep your Kern CNC machine running smoothly and efficiently for years. Regularly replacing worn parts and lubricating components will help minimize downtime and ensure that your production stays on schedule.

Maintaining Quality with Your Kern CNC Machine

The quality of the products produced by your Kern CNC machine is equally important as its efficiency when it comes to getting the most value out of your investment. To ensure that high-quality products are consistently produced from start to finish, it’s important to follow standardized procedures throughout the production process. This includes regularly inspecting components for defects or inconsistencies and calibrating tools and measuring devices prior to each use.

Additionally, having an experienced operator oversee operations can help prevent mistakes due to human error. Finally, investing in quality control systems can help catch any issues before they become costly problems down the line.

A Kern CNC machine is a major investment that requires careful consideration if you want to get the most value out of it. By following best practices such as proper setup and programming techniques, regular maintenance and inspections, and investing in quality control systems, you can ensure that your production runs efficiently while maintaining high-quality products from start to finish.

Ultimately, these efforts will pay off in spades by helping you make smart decisions about how best to utilize your investment in a Kern CNC machine throughout its lifetime!