What do You need to Know About CNC Machining Costs?

If you are planning on buying CNC machining services, it is important to understand how the cost of a particular job is determined. Many factors go into calculating the cost of a CNC machining project, and understanding these factors can help you make an informed decision when selecting the right provider. Let’s take a look at what goes into the cost of CNC machine time.

Time Required for Machining

The amount of time required for actual machining on a CNC machine plays a big role in determining its overall cost. Generally speaking, more complex jobs will require more time than simpler ones. This means that if your job requires intricate details or difficult shapes to cut out, you should expect it to take longer—and thus cost more—than if it were just a simple design with few steps involved in its completion. Additionally, some materials (such as aluminum) may require more time than others due to their properties and density.

Type of Machine Used

The type of machine used will also affect the total cost. For example, while a small desktop CNC machine will do the job just fine for smaller projects, larger projects may require industrial-grade machinery with higher tolerances and better accuracy in order to produce quality results. This is why discussing your project’s specifications with your potential service providers is important before deciding the one best suits your needs.

Material Type and Quantity

The material type and quantity used in each job also play an important role in determining its cost. Different types of materials have different properties that need to be taken into account when calculating costs—aluminum, for instance, is usually less expensive than steel but may require more machining time due to its density.

Additionally, larger quantities usually equate to lower costs per unit due to economies of scale; this means that if you are working on multiple parts at once, then the total cost should be lower than if they were machined separately over multiple batches due to setup costs being shared across all parts instead of having them incurred multiple times over separate runs.

All in all, there are many factors that go into determining the total cost of a CNC machining job. By carefully considering each factor and discussing them with potential service providers prior to selecting one for your project, you can get the best bang for your buck when it comes time to purchase your parts or components from a CNC machining shop. Ultimately, understanding what goes into determining the price tag associated with any given CNC machining job will help you make an informed decision when selecting which provider is right for your needs.

Calculating the Cost of CNC Machining Time

If you’re in the market for CNC machining, it’s important to know how to calculate the cost of CNC machine time. It can be daunting, but understanding each job’s cost is essential. Let’s break down how to calculate the cost of CNC machining time so that you can make informed decisions when selecting a service provider.

Direct Labor Costs

The first step in calculating the CNC machine time cost is understanding direct labor costs. This includes the hourly rate of each operator and any additional costs associated with their labor, such as benefits and overtime pay. The total labor costs should include all of these factors and be broken down into an hourly rate per operator per machine. For example, if an operator works on two machines for 8 hours, their total labor costs would be calculated by multiplying their hourly rate by 16 (8 hours x 2 machines).

Machine Operating Costs

The second step is to understand machine operating costs. This includes all costs associated with running and maintaining a CNC machining tool, such as electricity, cooling liquids, coolant disposal fees, repairs, maintenance contracts, and replacement parts. Depending on the type of tool being used and its age, these expenses can vary significantly from one job to another. The total operating costs should be calculated based on the type and age of each machine used in a given job.

Material Costs

The third step is to take into account material costs. This includes all raw materials used in a given job and any finishing supplies needed for post-processing work. These materials can range from metal rods or sheets to industrial adhesives or paints depending on the work being done. The total material costs should also include any additional fees associated with shipping or storage for purchased materials.

Calculating the cost of CNC machining time can seem daunting at first glance—but once you understand all the factors involved it becomes much more manageable. By taking into account direct labor costs, machine operating costs, and material costs you will have an accurate picture of what your job will cost before signing off on it. Doing so will help ensure that you get exactly what you need while staying within your budget!

What Factors Affect the Cost of CNC Machine Time?

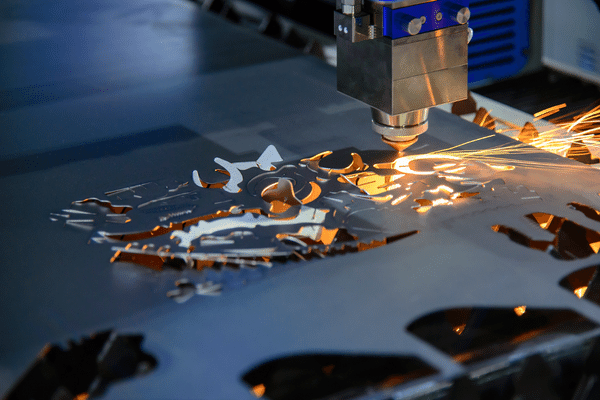

CNC machining is a manufacturing process that uses computer numerical control (CNC) tools to shape and form materials into desired components. CNC machining costs depend on several factors, including the type of machine used, the machined material, and the design’s complexity. In this blog post, we will discuss these three factors in more detail and how they can affect the cost of CNC machine time.

Type of Machine Used

The type of CNC machine used can affect the cost significantly, as different machines are suited for different applications. For example, a 3-axis milling machine is best suited for milling operations such as drilling and cutting with a spindle head that moves along three axes (X, Y, and Z). On the other hand, an EDM (electrical discharge machining) machine is ideal for cutting hard materials such as metals without using any extra force or heat. As you can see, each type of CNC machine has unique capabilities that can affect its cost.

Material Being Machined

The material being machined also affects the cost of CNC machine time. Different materials require different precision levels when cutting or shaping with a CNC tool. For example, softer materials such as plastics require less precision than harder materials like steel or aluminum. Additionally, different materials have varying degrees of durability and strength, which need to be considered when selecting a material for your project. This will ultimately determine how much time it takes to complete your project and thus affects the overall cost.

Complexity of Design

Finally, another important factor affecting the cost is your design’s complexity. If your design is complex or requires intricate details, it may take longer to complete than simpler designs due to additional time spent on setup and programming tasks before any actual cutting or shaping begins. Additionally, more complex designs often require additional steps such as finishing, adding extra costs to your project’s total cost estimate.

Overall, several factors can influence the cost associated with using a CNC machine; from type and material selection to complexity in design details – all these elements need to be considered when budgeting for a project involving CNC machining services. To ensure you get an accurate price estimate for your project, it’s best to speak directly with an experienced provider who can help you understand what needs to be done in order to achieve optimal results at an affordable price point. With their expertise at hand, you’ll be able to make informed decisions that best suit your needs while still staying within budget!

Determining the Right Time to Raise CNC Machine Rates

When it comes to determining the right time to raise rates for CNC machining, there are a few key factors to consider. You want to ensure you’re charging a rate that covers your costs and provides a profit, while also considering industry trends, customer needs, and competitive pricing. Here’s what you should know about raising rates for CNC machine time.

Review Your Costs Regularly

It’s important to keep track of your costs to determine whether it’s time to raise your rates. This includes both direct costs associated with producing parts on the CNC machine and indirect costs such as overhead expenses like rent, utilities, and insurance. By understanding the exact costs associated with each part you produce on the CNC machine, you can better evaluate whether or not raising prices is necessary in order to remain profitable.

Stay Up-to-Date on Industry Trends

In addition to monitoring your own expenses and profitability levels, it’s important to stay up-to-date on industry trends related to pricing. Keeping an eye out for changes in customer demand or competitors’ prices can help you anticipate when it might be time for a rate increase of your own. Additionally, if there have been significant upgrades made recently that improved the efficiency of your machines or reduced scrap rates, then this may be an indication that it’s time for a rate adjustment.

Consider Customer Needs

When deciding whether or not it’s time for a rate increase, it’s important to consider customer needs and market conditions. If customers have been consistently asking for higher quality parts at lower prices than what you’re currently offering them, they may be willing to pay more if those higher quality requirements are met—but only if they feel that the price is fair. It’s also worth noting that some customers may actually prefer paying slightly higher prices in exchange for improved delivery times or additional services from you like design assistance or product packaging options.

In conclusion, determining when is the right time for a rate increase for CNC machining is largely dependent on balancing cost considerations with customer needs and market conditions. By regularly reviewing your expenses and staying current on industry trends and competitive pricing data, you can make sure that any increases you do implement are justified based on cost increases or improvements in service levels—and ensure that customers remain happy with their experience working with you as well.

Negotiating the Best Rate for CNC Machining Time

When you are looking to purchase CNC machining time, it is important to understand the factors that go into negotiating the best possible rate. By understanding how to negotiate a rate properly and being aware of industry standards, you can ensure that you get the most out of your CNC machining purchase.

Factors That Affect Negotiations

When it comes to negotiating a rate for CNC machining time, there are several factors that will affect how much you pay. The primary factor is the project’s complexity and the material used in the process. The more complex the project, or if it requires unique materials, then the price will increase accordingly. Additionally, there may be an additional cost for any specialized tools or software that must be used for the job.

Another consideration is where you are getting your CNC machining done – if you’re working with a local shop or an overseas provider, that could impact both pricing and delivery times. It’s important to consider these factors before beginning negotiations so that you know what kind of rates to expect.

Finally, it’s important to look at what other companies are charging for similar services before entering into negotiations to ensure you’re getting a fair deal. Industry standards should also be taken into account when determining what types of offers are reasonable and which ones may not be worth considering.

Negotiation Strategies

Once all these factors have been taken into account, it’s time to start negotiating with potential providers. First and foremost, it is important to remain courteous throughout negotiations as this can help promote better communication between both parties and encourage cooperation during tough negotiations. It’s also helpful to remain flexible when negotiating – try offering different payment terms such as partial payments upfront or offering discounts if certain deadlines are met – in order to come up with mutually beneficial agreements. Finally, don’t forget to ask about any warranties or guarantees on services rendered in order to protect yourself in case anything goes wrong during production.

In conclusion, negotiating a rate for CNC machining time can be tricky, but by researching industry standards and understanding how different factors affect pricing, buyers can ensure they get a fair deal while still taking advantage of quality services from reliable providers. Additionally, employing negotiation strategies such as remaining courteous and flexible during talks can help buyers achieve their desired outcome while maintaining good relationships with potential partners. By following these steps carefully and thoughtfully, buyers can rest assured knowing they have made an informed decision when negotiating their CNC machining time purchase.

How to Calculate CNC Machine Time

If you’re looking to buy CNC machining services, you need to know how much time it will take for the job. The most accurate way to calculate machine time is by using sample quotes from the vendor. There are several factors that will affect the total cost of machining, including material selection, the complexity of the design, and finishing requirements. Let’s explore how this all works together to determine the amount of machine time needed for your project.

Material Selection

The material used in a CNC machining project impacts both the cost and the machine time required. For example, softer materials like aluminum require less cutting force than harder materials like steel or stainless steel. This means that projects made with aluminum can be completed in less time than those made with steel or stainless steel. Additionally, different types of metals have different cutting speeds, affecting machine time.

Design Complexity

The more complex a part is, the more operations need to be performed in order for it to meet specifications. This includes milling, drilling, tapping, and other machining processes that must be done with precision in order for parts to fit properly and function correctly. The more complex a design is, the longer it takes to program and complete all necessary operations correctly, increasing machine time.

Finishing Requirements

The type of finish required on a part also affects total machining time because it requires additional operations such as grinding or polishing, adding extra work hours to production times. Additionally, some finishes require multiple steps, adding even more hours to production times and costs due to increased labor hours and additional materials used in finishing operations like grinding wheels or polishing compounds.

Using sample quotes from vendors is an effective way to calculate CNC machine time accurately since sample quotes account for all variables involved including material selection, design complexity, and finishing requirements. It’s important to note that each vendor may have different pricing structures so it’s important to compare multiple quotes before making a final decision on who you want to hire for your CNC machining project needs. By understanding how sample quotes are calculated and what affects CNC machine times, you can make an informed decision when sourcing CNC machining services for your next project.