The Basics of CNC Machining

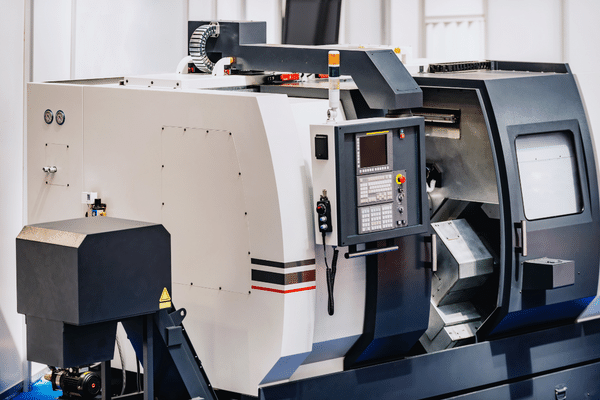

CNC machines are computer-controlled machining tools used for various industrial and commercial processes. From producing car parts to manufacturing medical devices, CNC machines offer precision and versatility in the production process. Let’s take a closer look at CNC machining, how it works, and what it can do.

How CNC Machines Work

CNC (Computer Numerical Control) machines use computer programming to control their movements. A user inputs instructions into a computer program, which then translates them into a set of commands that the machine can understand. This process is known as G-code programming. The machine then follows these instructions precisely, accurately performing cuts and shaping materials to create parts or components that meet exact specifications.

What Materials Are Used In CNC Machining?

CNC machines can cut and shape virtually any material from wood to steel, aluminum to plastic, and titanium to brass. They can also work with composites such as carbon fiber and fiberglass as well as foam and rubber products. Because there are so many different types of materials available in CNC machining processes, selecting the right material for your particular application is important.

What Are The Advantages Of Using A CNC Machine?

The primary benefit of using a CNC machine is its ability to produce accurate results with little waste or time invested in setup or production. Additionally, because all cutting and shaping are done by a computer-controlled system rather than manually operated tools, less human error is introduced into the process which means higher quality parts with greater consistency over time. Finally, because all programming is done on computers rather than manually on the machinery itself, designs can be easily modified or updated quickly if needed without having to re-program the entire process from scratch each time an adjustment needs to be made.

For buyers looking for a precise machining solution that offers cost savings and high levels of accuracy over manual processes, CNC machining may be an ideal choice. With its ability to work with virtually any type of material and its fast setup times combined with precise results every time, there are few other solutions that offer such comprehensive capabilities in one package. If you’re looking for an efficient way to produce parts or components quickly while still getting high-quality results every time, then you should consider investing in a CNC machine today!

An Overview of Different Types of CNC Machines

CNC machining is the process of creating parts and components using a computer numerical control (CNC) machine. CNC machines are used in a variety of industries, from automotive to aerospace and medical, to produce complex parts with a high degree of accuracy. Several different types of CNC machines are available on the market today, each designed for specific applications. In this article, we’ll take a look at the most popular types of CNC machines and how they can benefit your business.

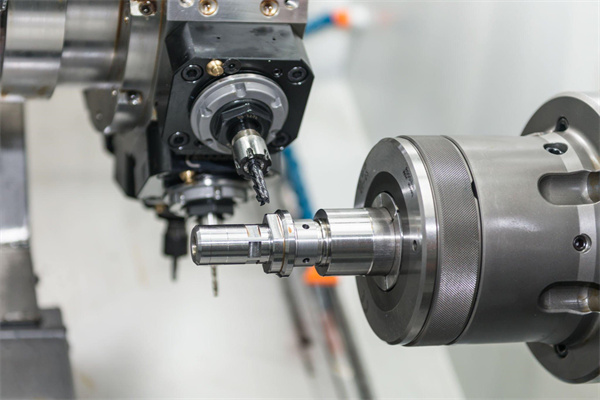

Lathe CNC Machine

Lathe CNC machines are the most common type of CNC machine used in industrial settings. They use cutting tools to shape materials into desired shapes by rotating them against stationary workpieces. They are often used for producing precision parts such as nuts, bolts, screws, and other small mechanical components.

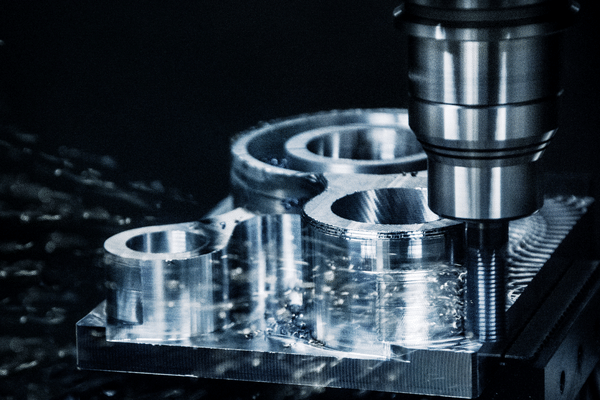

Milling CNC Machine

Milling machines use rotary cutters to remove material from a workpiece to create complex surface shapes or features. Milling machines can be horizontal or vertical depending on their orientation and are often used to produce intricate shapes such as slots and pockets. Additionally, they can also be used for producing threaded holes and grooves.

Drilling CNC Machine

Drilling machines are typically used for producing holes in workpieces by drilling out material from the surface with a rotating drill bit. These types of machines can be used for both shallow and deep-hole drilling applications depending on the size of the drill bits being used. They are often used in combination with milling or lathe machines for more complex operations such as counterboring or tapping threads into holes that have already been drilled out.

EDM (Electrical Discharge Machining) Machines

EDM machines use electrical sparks to erode away material from a workpiece without ever having to make contact with it physically. This makes them ideal for cutting very thin sections or small features on hard materials that would otherwise be impossible to cut using traditional machining methods such as drilling or milling. EDM machines can also be used to remove broken taps or drill bits stuck inside deep holes without damaging surrounding material during the extraction process.

When it comes time to buy a new CNC machine, there is no one-size-fits-all solution; what works best will depend entirely on your application requirements and budget limitations. The five types discussed above represent some of the most popular choices when it comes to selecting a new machine, but there are many others available as well including 3D printing systems, water jets, laser cutters, plasma cutters, etc… It’s important that you do your research before committing to any one type in order to ensure you’re getting exactly what you need at an affordable price point! With so many options available these days it can sometimes feel overwhelming trying to figure out which one is right for you, but hopefully, this article has given you some clarity about what type is best suited for your particular needs!

How to Utilize a CNC Machine for Maximum Effectiveness

CNC machining is an invaluable part of the manufacturing process, allowing manufacturers to create complex parts with precision and accuracy. That said, it’s important to understand that learning how to use a CNC machine can be difficult. Let’s take a look at the steps involved in mastering this valuable tool.

Learning the Basics of CNC Machining

The first step in understanding how to use a CNC machine is to learn the basics of Computer Numerical Control (CNC) machining. This involves understanding the different types of machines and their components and operations, such as programming, cutting tools, and materials. Understanding safety protocols and procedures are important when operating a CNC machine.

Gaining Practical Experience

Once the basics are understood, it’s time to gain practical experience working with a CNC machine. The best way to do this is by using a simulator or other training software programs that allow you to practice using a virtual machine without actually having access to one. This allows you to get comfortable with navigating the different menus and performing basic tasks before attempting anything on an actual machine.

Working With an Experienced Operator

Finally, once you have gained some familiarity with how the machines work and feel confident in your abilities, it’s beneficial to work with an experienced operator who can guide you through more advanced tasks. Working alongside someone who has mastered the craft will help you gain confidence in your own skills while also providing insight into potential problems that could arise during the operation and maintenance of a CNC machine.

Learning to use a CNC machine requires theoretical knowledge and practical experience. It’s important for those interested in purchasing or operating these machines to understand not just how they work but also safety protocols and procedures for successful operation. With patience and dedication, however, even total beginners will be able to master this valuable tool for maximum effectiveness in no time!

Who Can Benefit from Learning How to Use a CNC Machine?

CNC (Computer Numerical Control) machining is an incredibly useful tool for various industries and applications. It creates metal parts, plastic parts, and other components with consistent accuracy and repeatability. But who can benefit from learning how to use a CNC machine? The truth is that just about anyone can benefit from learning the basics of CNC machining.

Manufacturers & Consumers Alike

Manufacturers, consumers, and hobbyists alike can benefit from learning how to use a CNC machine. Manufacturers need to understand the basics of how the machine works in order to optimize its operation for their specific needs. This includes knowing how the software works and properly programming the machine for maximum efficiency. Consumers can also benefit from learning the basics of a CNC machine since it allows them to get more out of their purchases. Furthermore, hobbyists may find that they are able to save money on custom projects by taking on some of the fabrication work themselves using a CNC machine.

The Advantages of Learning CNC Machining

Learning to use a CNC machine has several advantages over traditional manufacturing methods. For one, it eliminates human error since the parts are created by computer-controlled machines instead of manually operated equipment. Additionally, it allows parts to be produced with extremely high precision and repeatability compared to other types of machining processes such as milling or drilling. Finally, it also offers faster production times because multiple parts can be made simultaneously with minimal setup time required before each part is created.

Overall, there are many benefits associated with learning how to use a CNC machine, and virtually anyone can gain something from mastering this skill set. Whether you are an experienced manufacturer looking for an edge in your industry or an individual looking for an efficient way to create custom projects at home, understanding how a CNC machine works will provide you with maximum flexibility in your operations while minimizing costly errors. With today’s technology making this type of machinery more accessible than ever, there’s never been a better time than now for buyers interested in purchasing CNC machining services or their own machines!

Training for CNC Machining Buyers

CNC machining is a highly specialized and technical process that requires advanced knowledge and expertise. If you are considering buying a CNC machine, it is important to understand the type of training and support available to ensure successful operation. In this blog post, we will discuss the different types of training available for CNC machining buyers.

On-Site Training

The most comprehensive training option is on-site training. This means that an experienced professional will come to your facility, assess your needs, and provide hands-on instruction. On-site training can be tailored to your exact needs and the specific machine you are using. The benefit of this type of training is that you have direct access to someone who understands the machine and can answer any questions you may have while operating it.

Online Training

Another option is online training. This type of training can be more convenient than on-site and often more cost-effective. Online courses are typically self-paced, so you can go at your own speed and review the material as needed. Many online courses also include videos or other visual aids that make it easier to understand how to operate a CNC machine correctly.

Instructor-Led Courses

Finally, instructor-led courses provide another way to learn how to use a CNC machine safely and effectively. These courses are usually held in a classroom setting with an experienced instructor providing step-by-step guidance on the operation of the machine. Some instructor-led courses may also include hands-on practice sessions where participants get the opportunity to work with actual machines in order to gain valuable experience in operating them properly.

CNC machining buyers should consider all their options when it comes to finding the perfect training solution for their needs. On-site training provides direct access from an experienced professional, while online classes allow users more flexibility in terms of learning at their own pace or revisiting material as needed. Instructor-led courses provide another great way for learners to gain hands-on experience with actual machines before putting theory into practice in their own facilities. No matter what type of CNC machining buyer you are, there’s sure to be a perfect learning solution out there for you!

The Cost of Learning to Use a CNC Machine

CNC (computer numerical control) machines are used in various industries, from aerospace and automotive manufacturing to woodworking and jewelry making. A CNC machine is an incredibly powerful tool that can create complex parts with precision and speed. However, for those new to working with such machines, the cost of learning how to use one can be daunting. In this blog post, we’ll explore the cost of learning to use a CNC machine and provide advice on how to reduce expenses while still getting the most out of your investment.

The Cost of Training

The cost of learning how to operate a CNC machine will depend on the type of training you need and the complexity of your project. Generally speaking, basic operation courses cost anywhere from $100-$200 per hour while more advanced courses can run up to $1000 or more. Additionally, some companies may offer discounts if you’re willing to sign up for multiple classes at once or participate in their online training program. It’s important to research different training options before committing to getting the best value for your money.

If you’re looking for more personalized instruction, private tutors are available who specialize in teaching CNC skills. Private tutoring sessions typically come with a higher price tag—anywhere from $50-$150 per hour—but they also provide more hands-on attention than group settings. Depending on your budget and skill level, private tutoring may be worth considering as an option when learning how to use a CNC machine.

Reducing Expenses

Aside from researching different training options, there are other ways to reduce the cost of learning how to use a CNC machine. For starters, it’s important that you have access to all the necessary tools and materials needed for each project before beginning any work; this will save both time and money in the long run as you won’t have to go through multiple trial-and-error cycles when trying out new techniques or ideas.

Additionally, many shops offer discounts if you’re willing to purchase supplies in bulk or sign up for their membership program; these offers should always be taken advantage of if possible since they can help reduce overall costs significantly over time. Finally, it’s worth mentioning that some software programs have free versions available; these versions may not have all the features that paid versions do, but they can still be useful for getting familiar with basic operations before taking on more advanced projects down the line.

Learning how to use a CNC machine is no small feat—it requires dedication and practice in order to master its complexities fully—but it’s definitely achievable with some patience and financial planning. By researching various training options available and taking advantage of discounts offered by suppliers or software programs whenever possible, you’ll be able to keep costs low while still getting all the knowledge needed to become an expert operator over time. With enough practice and hard work, anyone can proficiently learn how to operate a CNC machine!