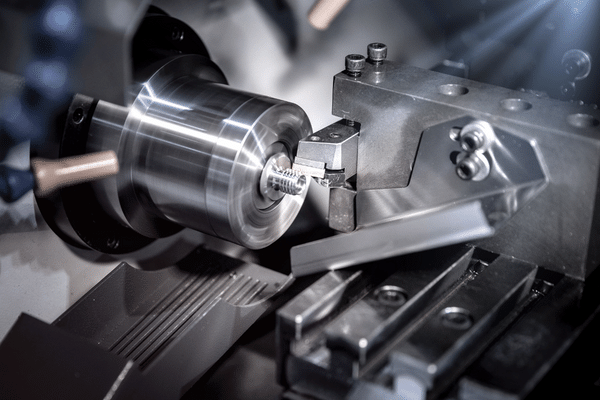

CNC aluminum machining

Offer aluminum CNC machining parts with precise processing techniques and quick cycle time at a competitive price.

Home » CNC Aluminum Machining

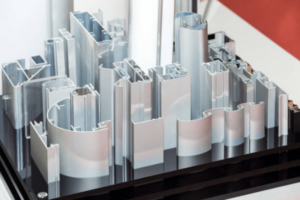

aluminum machining china - CNC Aluminum Parts

Looking for reliable, quick-turn Aluminum CNC machining services suppliers and CNC Machined product manufacturers?

With 13 years of experience in the manufacturing industry, we can provide our customers with high-quality products and services.

We specialize in aluminum CNC machining services and CNC machined parts production. We can design and manufacture all kinds of aluminum parts according to your requirements.

Our experienced engineers can help you achieve your goals efficiently. We also offer CAD/CAM software solutions to ensure that you get exactly what you need at an affordable price. No matter what kind of aluminum parts you need, we will be able to meet your needs and exceed your expectations!

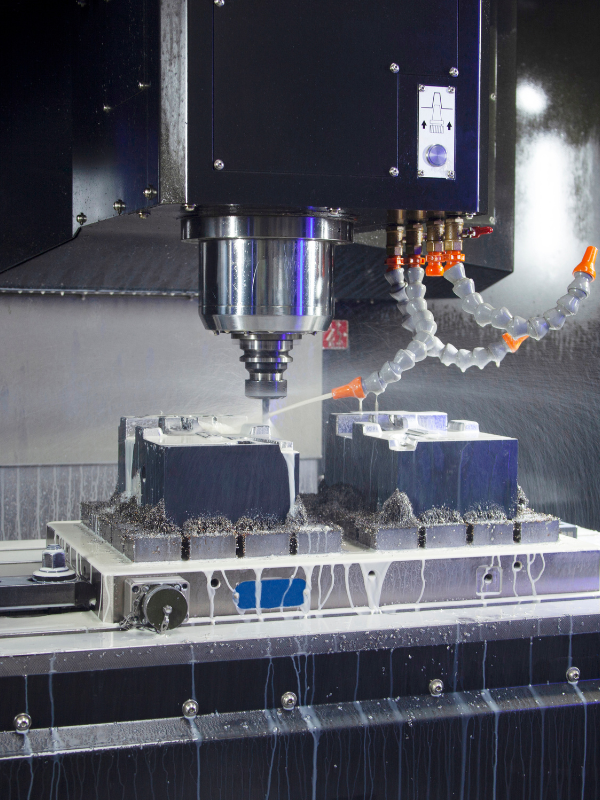

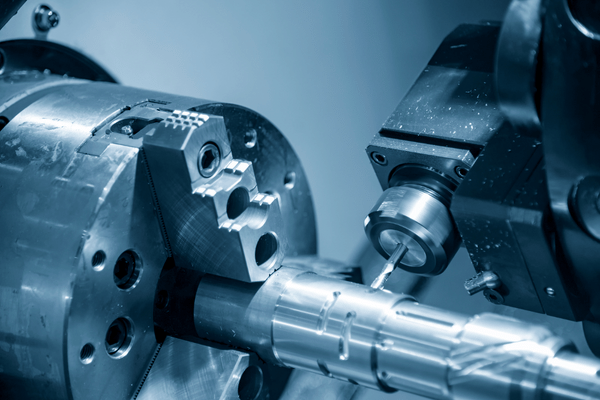

What is CNC Aluminum Machining?

CNC aluminum machining is a process of making aluminum parts by using a computer to control the movement of the cutting tool. It is also called CNC machining, and it allows for more precise and intricate parts with less waste than other processes. This method can make any type of aluminum part, including gears, shafts, and housings.

What Are the Advantages of Cnc Aluminum Machining?

♦Speed – A CNC machine can create parts much faster than traditional methods like milling or lathe work. The speed of these machines makes them perfect for producing small batches of parts or one-off jobs that would otherwise be too expensive or time consuming using older methods.

♦Cost – CNC machining also costs less than other manufacturing processes because it uses fewer man hours and there’s less setup involved before production starts.

♦Accuracy – Most CNC machines come with built-in probes that allow them to measure their position with extreme accuracy so they can produce parts with very tight tolerances without requiring any manual adjustments from the operator during production runs

Benefits of Aluminum Material (CNC Aluminum Parts

1. Lightweight: The aluminum material is very lightweight, which means that a lot of weight can be reduced. This makes it easier to lift or move the products.

2. Corrosion-resistant: Aluminum is known to be corrosion-resistant and durable. It can last longer than most other materials, which make it ideal for vehicles and other transportation equipment.

3. Wide range of applications: There are many different applications that aluminum can be used for, including construction and architecture, electronics, household appliances and more.

ETCN- CNC Aluminum Machining Specialist

ETCN is a full-service precision metalworking company specializing in the production of complex parts from aluminum and stainless steel. We have been in business since 1979 and are ISO 9001:2015 certified.

machining aluminum materials

Aluminum 6061, Aluminum 2024, Aluminum 5052, Aluminum 6063,Aluminum 7050,Aluminum 7075,Aluminum MIC-6

Surface Finishing

Sand blasting, shot blasting, polishing, anodizing, oxidation, electrophoresis, chromate, powder coating and painting

Aluminum CNC Machining Applications

What can apply aluminum CNC parts for automotive, electrics, military, medical, aircraft, power generation, aerospace, and industrial engineering?

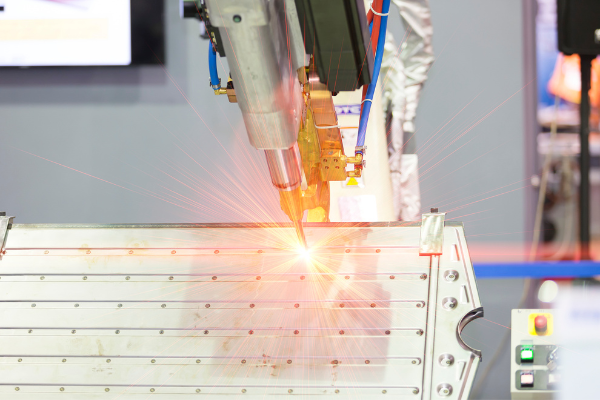

Are standard or custom CNC Aluminum Parts available?

Yes, we offer both standard and custom CNC Aluminum Parts. However, the material type of your part will determine which process is best suited for you. If your parts are made from aluminum, we can use CNC milling or laser cutting to create them for you.

Advantages of ETCN Aluminum CNC Machining Services

ETCN provides a wide range of services for aluminum milling machines. Our machining services are available for companies in the medical and defense industries and those in the aerospace industry. We have a skilled and experienced team ready to help you with your machining needs. Here are some of the advantages of our aluminum CNC milling services:

♦Time-Saving – Our expertise saves you time by taking care of all aspects of your project from start to finish. We also work with you throughout the process so that you can focus on other important aspects of your business.

♦Cost Effective – Our low overhead costs allow us to provide affordable pricing on all our machining services. You won’t be surprised by any hidden fees or charges once we start your project!

♦Quality Workmanship – Since we have been doing this work for many years, we have developed excellent quality control measures to ensure that each part produced meets or exceeds customer specifications.

♦Experienced Staff – Our highly skilled staff has been doing this for decades! They know all there is to know about CNC machining and can help you select the right equipment for your needs.

Wholesale CNC Machining Aluminum Parts Factory

#1. Repeatability

- One of the biggest advantages of CNC machining is repeatability.

- This means that the same part can be produced repeatedly with the same high degree of accuracy.

- This is because CNC machines are controlled by computers, which means they can reproduce the same movements repeatedly with great precision.

#2. Speed

- CNC machining is also much faster than traditional machining methods.

- This is because the machine operator does not have to set up each part manually. Instead, they have to load the desired program into the machine and let it do its work.

- This increased speed makes CNC machining an ideal choice for mass production.

#3. Precision

- As we mentioned before, CNC machines can produce parts with high accuracy.

- This is because computers control them, meaning they can follow precise instructions.

- Additionally, CNC machines are equipped with cutting tools that can achieve tolerances as low as 0.001 inches.

#4. Versatility

Another advantage of CNC machining is versatility. This is because these machines can be used to create parts from a wide variety of materials, including metals, plastics, and composites. Additionally, CNC machines can create parts of varying sizes and shapes.

#5. Cost-Effectiveness

- CNC machining is also a cost-effective manufacturing method compared to other methods, such as 3D printing or molding and casting.

- This is because it does not require special equipment or materials to produce parts.

- Additionally, CNC machined parts typically have a longer lifespan than those produced by other methods, thanks to their increased durability.

As you can see, there are many advantages to using CNC machining to produce metal parts. Thanks to its repeatability, speed, precision, versatility, and cost-effectiveness, it has become one of the most popular manufacturing methods. Contact a reputable wholesale CNC aluminum factory today if you need high-quality metal parts for your business or project!

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.

aluminum CNC machining FAQs

Frequently Asked Questions.

Is aluminum difficult to machine?

- The answer may surprise you – aluminum is easier to machine than many other metals.

- One reason for this is that aluminum chips easily make it easy for CNC machine operators to quickly and accurately create complex parts.

- In addition, aluminum has a low melting point, which means it can be machined at high speeds without damaging the tools.

- As a result, aluminum is an excellent choice for applications where speed and accuracy are critical.

Is it better to cut aluminum fast or slow?

- When it comes to cutting aluminum, there is no one-size-fits-all answer.

- The best method will vary depending on the type of aluminum being cut and the desired result.

- However, cutting aluminum slowly and carefully will produce a cleaner and smoother edge. Meanwhile, Cutting aluminum quickly may be necessary when time is limited or when a rougher edge is acceptable.

- Ultimately, the best way to cut aluminum will depend on the specific circumstances and desired outcome.

What RPM should you mill aluminum?

- When machining aluminum on a milling machine, it is important to use the correct RPM (revolutions per minute).

- If the RPM is too high, the cutting tool will overheat and damage the workpiece. If the RPM is too low, the tool will simply bounce off the surface of the metal and will not create a clean cut.

- The best way to determine the optimal RPM for milling aluminum is to consult a machining reference chart.

- These charts list the recommended speeds for various materials based on the cutting tool used. By choosing the correct RPM, you can ensure that your aluminum parts are machined accurately and with high precision.

How many flutes does it take to mill aluminum?

The answer is typically around 30. That’s a lot of flutes! However, the large number of flutes helps to minimize damage to the metal and produce a high-quality finish. So, if you’ve ever wondered how many flutes it takes to mill aluminum, the answer is 30.