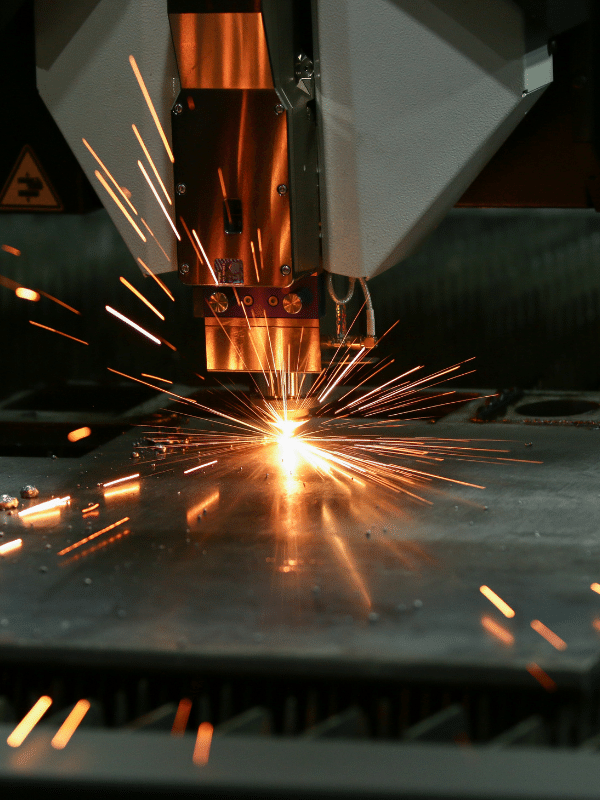

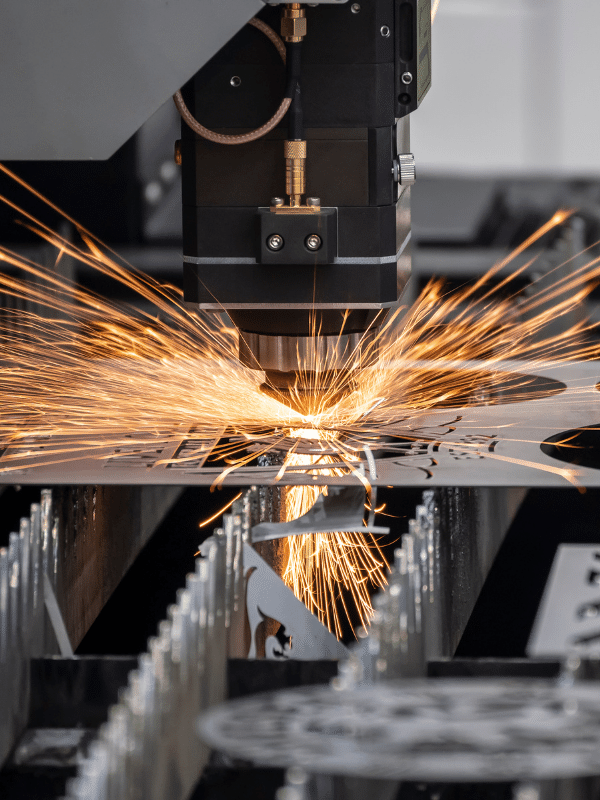

CNC laser cutting services

ETCN provides the best CNC laser cutting services from china. With 14 years of experience in CNC Laser cutting and professional service, ETCN is your best choice.

Home » CNC Laser Cutting Services

What is Cnc Laser Cutting Services?

- CNC laser cutting is a manufacturing process that uses a computer-controlled laser to cut materials. It is one of the most advanced and precise forms of laser cutting.

- CNC laser cutting machines produce complex parts with high precision and accuracy, making them ideal for prototyping and small production runs.

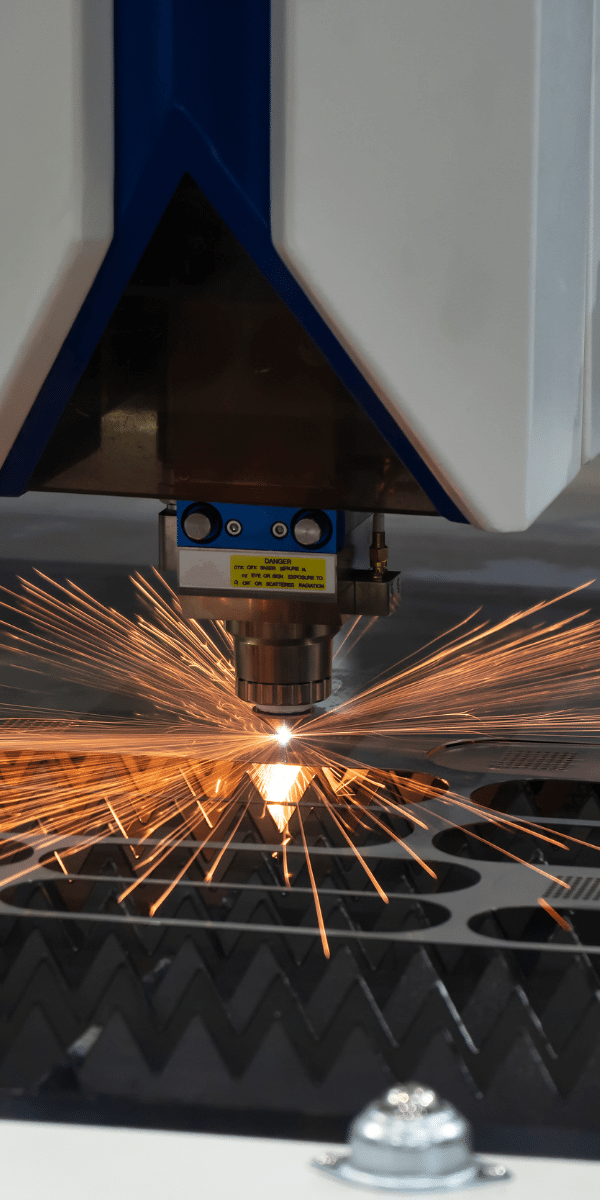

- The principle of laser cutting: laser cutting is to use a focusing mirror to focus the laser beam on the surface of the material so that the material melts while using the compressed gas coaxial with the laser beam to blow away the melted material and make the laser beam and the material along a certain track for relative movement, to form a certain shape of the cut.

- Application areas for laser cutting: Machine tools, engineering machinery, electrical switch manufacturing, lift manufacturing, grain machinery, textile machinery, locomotive manufacturing, agricultural and forestry machinery, food machinery, special vehicles, petroleum machinery manufacturing, aerospace, environmental protection equipment, household appliance manufacturing, large motor silicon steel sheet and other various machinery manufacturing and processing industries.

Advantages of Cnc Laser Cutting Services

1. High accuracy: 0.05mm positioning accuracy, 0.02mm repeat positioning accuracy

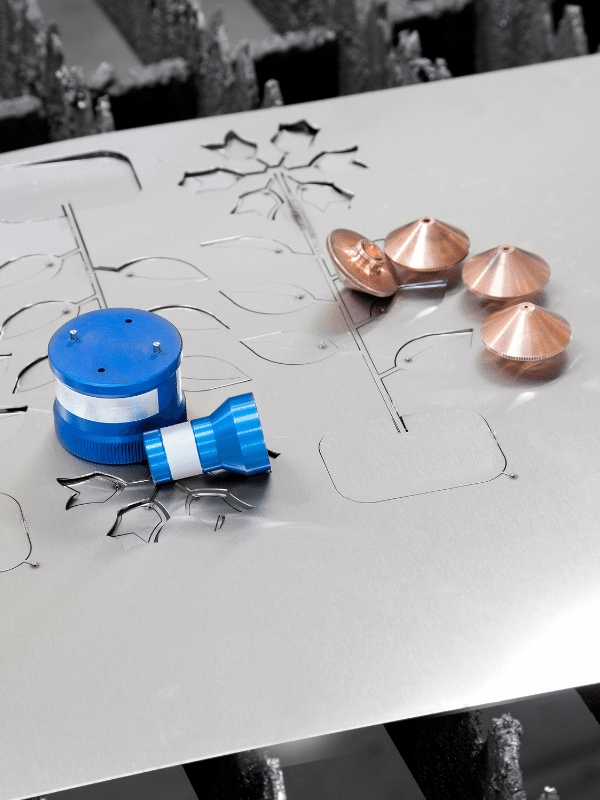

2. Narrow slit: the laser beam is focused into a very small spot so that the focal point reaches a very high power density. The material is quickly heated to the degree of vaporization and evaporates to form a hole. With the relative linear movement of the beam and the material, the hole is continuously formed into a very narrow width of the cut. The width of the cut is generally 0.10 to 0.20mm.

3. Smooth cutting surface: the cutting surface is burr-free, and the surface roughness of the kerf is generally controlled within Ra12.5.

4. Fast speed: cutting speed up to 10m/min, maximum positioning speed up to 70m/min, much faster than the speed of wire cutting.

5. Good cutting quality: no contact cutting, the cutting edge is very little affected by heat, basically no thermal deformation of the workpiece, completely avoid the collapse of the edge formed when the material punching and shearing, the cutting seam generally does not require secondary processing.

6. No damage to the workpiece: the laser cutting head does not come into contact with the material’s surface, ensuring that the workpiece is not scratched.

7. Not affected by the hardness of the material to be cut: the laser can process steel plates, stainless steel, aluminum alloy plates, hard alloys, etc… No matter what hardness, it can be cut without deformation.

8. Not affected by the shape of the workpiece: laser processing is flexible, can process any graphics, and can cut tubes and other profiles.

9. Can cut and process non-metals: such as plastic, wood, PVC, leather, textiles, organic glass, etc.

10、Saving investment in molds: laser processing does not need molds, no mold consumption, no need to repair molds, saving time to replace molds, thus saving processing costs and reducing production costs, especially suitable for processing of large products.

11. Saving material: With computer programming, the whole board material can be set and cut for different shapes of products, maximizing the utilization of material.

12. Improve the speed of new product development: laser processing can be done immediately to get the new product in kind in the shortest possible time after the product is formed.

Advantages of CNC Laser Cutting Services

1. Laser cutting has a narrow slit and small workpiece deformation

- The laser beam is focused into a very small spot so that a very high power density is achieved at the focal point. At this point, the heat input from the beam far exceeds that reflected, conducted, or diffused by the material, which is quickly heated to the point of vaporization and evaporation to form a hole. As the beam moves linearly relative to the material, the holes are made to form a continuous slit of very narrow width. The heat minimizes the cutting edge, and there is no workpiece deformation.

- Auxiliary gases suitable for cutting material can be added during the cutting process. When cutting steel, oxygen is used as auxiliary gas to oxidize the material in an exothermic chemical reaction with the molten metal and to help blow away the slag in the cut. Compressed air is used to cut plastics such as polypropylene, and inert gas is used to cut flammable materials such as cotton and paper. The auxiliary gas entering the nozzle also cools the focusing lens, preventing soot from entering the lens holder, contaminating the lens, and causing it to overheat.

- Most organic and inorganic materials can be cut by laser. In the metal processing industry, which plays a large part in the industrial manufacturing system, many metallic materials, regardless of their hardness, can be cut without distortion. Of course, fiber lasers can recently be used for cutting highly reflective materials such as gold, silver, copper, and aluminum alloys, which are also good conductors of heat transfer and are difficult to cut with conventional lasers.

- Laser cutting is burr-free, wrinkle-free, highly accurate, and superior to plasma cutting. For many electromechanical manufacturing industries, as the microcomputer program-controlled modern laser cutting system can facilitate the cutting of different shapes and sizes of workpieces, it is often preferred over punching and molding processes. However, it is still slower than mold punching. It has no mold consumption and no need to repair molds and also saves time in replacing molds, thus saving processing costs and lowering production costs. Hence, it is more. It is, therefore, more cost-effective overall.

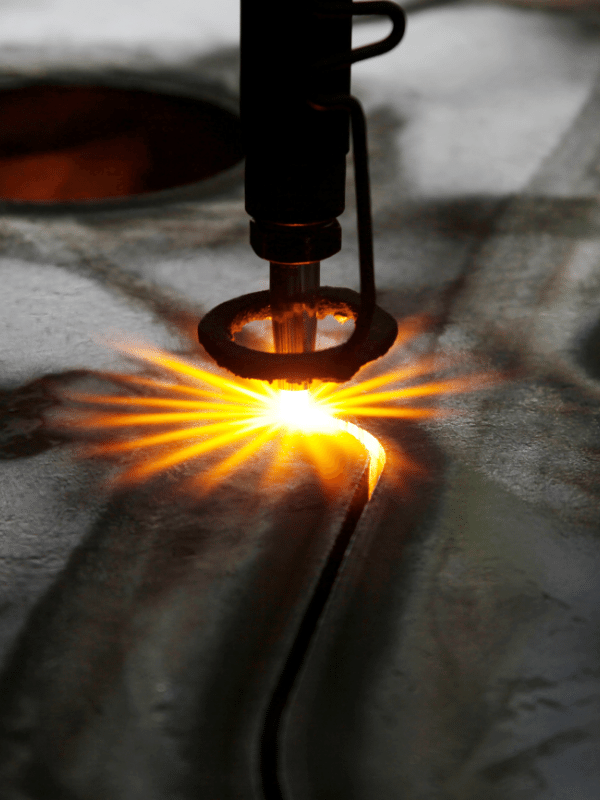

2. Laser cutting is a contactless process with high energy and good density control

- Firstly, the conversion of laser light energy into amazing heat energy is kept in a very small area, providing (i) a narrow straight edge cut; (ii) a minimal heat affected zone adjacent to the cut edge; and (iii) very little local deformation.

- Secondly, the laser beam does not exert any force on the workpiece. It is a contactless cutting tool, which means (iv) no mechanical deformation of the workpiece; (v) no tool wear and tear and no talk of tool changeover; (vi) no need to consider the hardness of the material being cut, i.e., the laser cutting capability is not affected by the hardness of the material being cut, any hardness can be cut.

- Again, the laser beam is highly controllable and has high adaptability and flexibility; thus, (vii) it is convenient to combine with automatic equipment and easy to automate the cutting process; (viii) as there is no restriction on the workpiece to be cut, the laser beam has an infinite ability to cut in imitation; (ix) combined with a computer, the whole board can be scheduled to save material.

3. Laser cutting has a wide range of adaptability and flexibility

Compared to other conventional processing methods, laser cutting offers greater adaptability. Compared to other thermal cutting methods, which are also thermal cutting processes, other methods cannot act on a very small area like the laser beam, resulting in a wide kerf, a large heat affected zone, and significant workpiece distortion. Lasers can cut non-metals in a way other thermal cutting methods cannot.

Main Processes for Laser Cutting

♦ 1. Vapor cutting

♦ 2. Melting cutting

♦ 3. Oxidation cutting

♦ 4. Controlled fracture cutting

The Definitive Guide: Main Processes for Laser Cutting

Process parameters for cutting aluminium sheets

| Duty cycle | 20 | 25 | 25 | 25 | 25 | 25 | 25 | |

|---|---|---|---|---|---|---|---|---|

| Stop Delay Time | Sec | 0.2 | 0.2 | 0.5 | 1 | 1 | 1 | 2 |

| Focus position | mm | -0.5 | -1 | -2 | 0 | 0 | 0 | 0 |

| Auxiliary gas O2 pressure | bar | 1 | 1 | 1 | 2 | 1 | 1 | 1 |

| small circle | ||||||||

| Trouble light mode | SP | SP | SP | CW | CW | CW | CW | |

| Laser frequency | Hz | 200 | 750 | 750 | ||||

| Laser power | W | 800 | 1200 | 1200 | 1500 | 1500 | 1800 | 2200 |

| Gou-space ratio | % | 25 | 50 | 55 | I | |||

| Feeding speed | mm/min | 500 | 1300 | 1000 | 900 | 700 | 800 | 500 |

| Large circle | ||||||||

| Laser mode | CW | CW | CW | CW | CW | CW | CW | |

| Laser power | W | 1200 | 1500 | 1500 | 2200 | 2200 | 2200 | 2200 |

| Feed rate | mm/min | 3000 | 2500 | 1800 | 1600 | 1300 | 1000 | 500 |

Aluminum Laser Cutting Services

Aluminum Laser Cutting Services is a process that uses a laser to cut metal sheets. The laser cutting process is highly used in manufacturing industries as it is cost-effective and precise. The advantages of Aluminum Laser Cutting Services are:

- 1. Long-term service life, not to mention the low maintenance cost.

- 2. The most advanced cutting technology is more precise than other methods.

- 3. Easy cutting and high efficiency, the material consumption is minimized, which greatly impacts production costs and environmental protection.

- 4. High precision processing can meet customer needs for fine details in design requirements, such as small holes or curved surfaces.

- 5. With the development of laser technology, many new applications have been developed for laser-cutting aluminum products, such as laser drilling and marking (laser engraving).

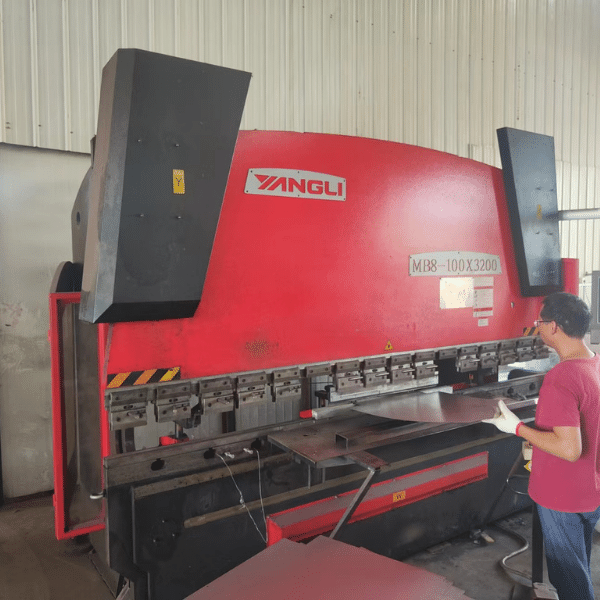

custom sheet metal laser cutting

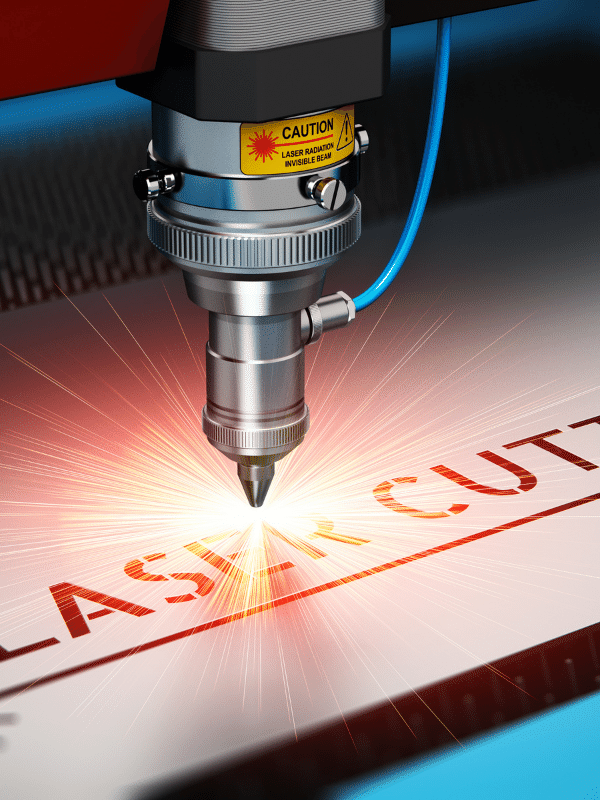

♦ Custom Sheet Metal Laser Cutting is a fast, cost-effective, and environmentally friendly manufacturing method. The process uses a computer-controlled laser to cut material by burning through the material in a carefully controlled cut pattern.

The advantages of custom sheet metal laser cutting are:

- Speed – A single piece can be cut in seconds. This makes it possible to manufacture small batches of products, which may be impossible using conventional methods such as stamping or casting.

- Accuracy – The laser cuts material with an accuracy of +/- 0.005 inches (0.127 mm). This means that complex parts can be made without the need for expensive tooling or jigs and fixtures that may be required with other manufacturing methods, such as milling or turning, where tolerances are less precise.

- Material selection – Once again, because of the accuracy of the process, many materials can be used that could not be machined by other processes such as turning or milling due to their high hardness or brittleness (e.g., titanium). It also allows non-metallic materials such as plastics to be used where they would not normally be suitable for machining due to their high melting point or hardness (e.g., nylon).

laser cutting companies From china

ETCN is a leading laser cutting and engraving company with 25 years of experience in the laser cutting industry. Our new state-of-the-art facility can provide our customers with top-quality work at an affordable price.

We are committed to providing our customers with the highest level of service while maintaining an efficient production process. We have a wide variety of cutting materials available in our laser machines, including stainless steel, aluminum, carbon steel, galvanized steel, and more. We also offer a wide array of materials for engraving and etching, including acrylics, wood, glass, and more!

Laser cutting services include simple shapes, complex contours, or even intricate 3D models. We can cut through just about anything from paper to metal as long as it fits in our machine! If you need something cut out that doesn’t fit into one of these categories, don’t hesitate to contact us so we can discuss your options further!

custom laser cut parts

Custom laser cut parts are ideal for companies who want to create a customized product and don’t want to spend money on expensive molds.

At our factory, we have a team of experienced designers and engineers who can work with you to design your custom laser-cut parts. We can then manufacture these parts using powerful CNC machines to achieve the high accuracy needed for your application.

Laser cutting is an excellent way of manufacturing small or large quantities of customized parts as they can be designed to be as simple or complex as you need them to be. We can cut from stainless steel up to 20mm thick and aluminum up to 4mm thick.

Benefits of Laser Cutting:

- High accuracy – Our CNC machines allow us to achieve the high level of accuracy needed for your application

- Low tooling costs – No expensive molds required! Just send us your designs, and we will cut them on our CNC machines

- Fast turnaround time – Send us your designs today, and we can ship them off tomorrow!

aluminum laser cutting services

Aluminum laser cutting services from China, we provide high-quality aluminum laser cutting services and the best price.

Aluminum Laser Cutting Service Description:

- 1. Material: Aluminum Alloy or Stainless Steel

- 2. Max Cutting Thickness:6mm

- 3. Max Cutting Length:8m (Longer length is available upon request)

- 4. Cutting Accuracy: +/- 0.1mm (Depends on material and thickness)

laser tube cutting service

♦ The laser tube cutting service is fast and accurate. It can cut any non-metal materials such as wood, plastic, glass, and rubber.

♦ The laser tube cutting machine uses a high-power laser beam to cut the material. The working principle of this equipment is to use high-power laser light to melt the material’s surface to be cut and then evaporate it into the atmosphere. The process is simple, fast, and accurate.

The advantages of laser tube cutting

Cutting accuracy depends on the power of laser tubes and the stability of their operation environment. Using low-power laser tubes can achieve 0.01mm precision; With moderate-power laser tubes, it can reach 0.05mm; For high-power laser tubes, there are technical limits on the precision (because of how long the tubing is).

Compared with traditional mechanical processing methods, laser tube cutting has shorter processing times and uses less labor costs. It takes only several seconds to cut a thick plate with a diameter of 6 meters; For thin plates or other materials that need to be welded together after being cut must also be welded together before being sent back for further processing so that the laser beam will not damage them.

Laser tube cutting does not produce any burrs on the cut surfaces and can be directly used for further processing; As a result, there is no need to remove burrs or clean up the edges of the workpiece.

Laser tube cutting is suitable for most materials, including steel, stainless steel, aluminum and other nonferrous metals; In addition to the processing of flat products, it is also possible to process round tubes with diameters up to 4 meters.

Laser tube cutting has high precision and can be used to cut complex shapes such as small holes, corners and grooves;

Because the laser beam does not affect the workpiece during processing, there is no deformation.

The cutting speed of the laser tube is much faster than other types of processing.

There is no need to use water or compressed air during processing.

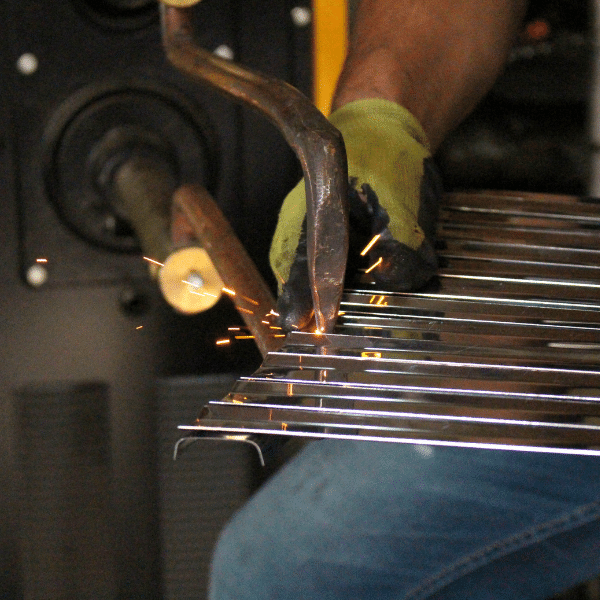

sheet metal punching service

Sheet metal punching service from china is a service that allows you to produce your sheet metal parts easily. No need to invest in expensive machinery or tools. We can make your parts for you!

The advantages of sheet metal punching service:

- 1. Cheaper than buying tools and equipment

- 2. Quicker than 3D printing

- 3. You can use our machines 24/7 (no waiting in line)

- 4. There are no minimum order quantities (MOQs).

- 5. We can make any size of sheet metal parts

- 6. The parts are made from high-quality materials

- 7. You get to keep your intellectual property (IP)

- 8. There is no need for you to visit our factory

- 9. We can ship your parts anywhere in the world

stainless steel laser cutting

Laser cutting is cutting materials by applying heat from a high-power laser beam. The laser beam is usually focused through optics and travels at a high velocity. The cut’s speed, quality, and precision are based on the wavelength of the laser beam and its power. Laser cutting is used for cutting steel, aluminum, stainless steel, and other non-ferrous metals. It can also cut plastics, paper, textiles, and food products.

The advantages of stainless steel laser cutting:

- 1. High quality: Stainless steel plate has good corrosion resistance, it can be used in seawater environment

- 2. Good strength: Stainless steel plate has excellent mechanical properties so that it can be used for large-scale structures

- 3. Good toughness: Stainless steel plate has good fatigue strength and is not easy to crack under load

- 4. Good stability: Stainless steel plate has good thermal stability and low thermal expansion coefficient, which makes it suitable for high-temperature application

brass laser cutting

The brass laser cutting is a kind of laser cutting in which the laser beam is reflected on the brass material to cut it. The cutting depth can be controlled by adjusting the power of the laser. As a result, it achieves higher efficiency and high precision cutting than other methods.

The advantages of brass laser cutting:

- 1. With high accuracy, good surface finish, and better quality than other methods of metal processing;

- 2. No burr or damage to the edge of the material;

- 3. No deformation and distortion during processing;

- 4. The waste generated during processing can be recycled after treatment;

- 5. High efficiency, short lead time;

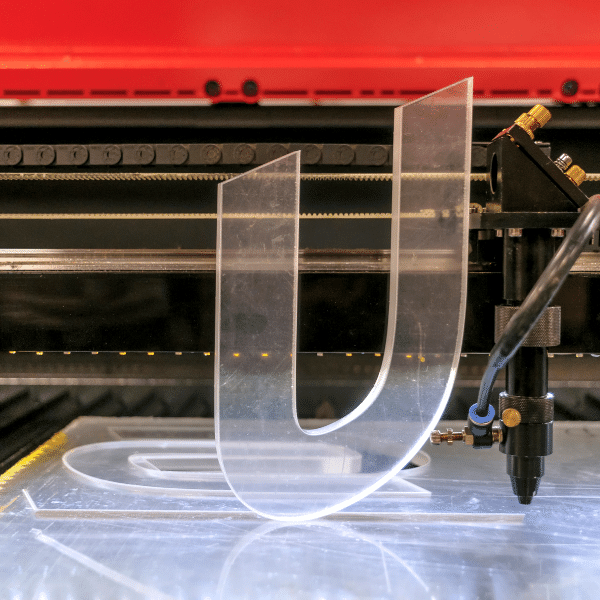

laser cut acrylic

Laser cut acrylic is made from clear and colored acrylic sheets. Our laser cutting machine can cut any shape or size you want.

Advantages of Laser Cut Acrylic:

1. Clean and precise cutting result, no burrs or burring

2. Fast cutting speed, fast delivery time, and competitive price

3. Versatile material for different applications such as signage , display board, store fixture, furniture parts, and many more

4. Environment-friendly material and easy to recycle

laser wood cutting services

Laser wood cutting services are a widely used technique for the cutting of woods. It is a process that involves the use of high-powered laser beams to cut through wood.

The laser beam is produced by a highly concentrated light source that emits single pulses of light in the form of an intense, coherent monochromatic light beam.

The advantages of using laser wood cutting services include:

- 1. They have a high level of accuracy, which means that you can be sure that your cuts will be precise and accurate.

- 2. They are fast and efficient; they can save time and effort while making more precise cuts than other methods like sawing or chiseling would allow you to make.

- 3. They do not require any physical contact with the material being cut, which means there is no risk of injury from flying debris or splinters from the cut material.”

laser cutting cardboard

Laser cutting cardboard services is a kind of laser cutting technology widely used in the paper processing industry.

Advantages of Laser Cutting Cardboard Services:

- 1. High precision, no burr, and no smoke;

- 2. Low power consumption, save energy, and high efficiency;

- 3. Small volume, lightweight, convenient transportation, and installation;

- 4. Environmental protection with the advantages of high-tech gas laser tube and imported focusing lens and mirror;

- 5. Easy to operate and maintain, easy to learn how to use;

leather laser cutting services

Leather laser cutting is used to cut the leather into different shapes and sizes. The leather laser cutting services are used for many applications like footwear, garments, handbags, and many more.

Advantages of leather laser cutting services:

- 1. High efficiency, cutting speed is 10 times faster than traditional mechanical processing methods;

- 2. High precision, the thick plate can be cut into a 0.3mm thin plate;

- 3. No burrs, no burrs after cutting;

- 4. No deformation under high temperature;

- 5. Easy to operate and maintain;

laser cut companies

Laser Cut Companies from china

ETCN is a professional Laser Cut Companies from china manufacturer and supplier, providing the best quality products with the most competitive price. You can rest assured of buying our product.

Service Description

- 1. High precision, high speed, high strength, low energy consumption, and easy maintenance;

- 2. Using imported high-quality steel plate production, cutting components have good rigidity;

- 3. Equipped with an automatic alarm system when the laser is overloaded and automatically shut down when power exceeds the set value to ensure the safety of operators;

- 4. The machine has a large processing area and high efficiency; it can be used for cutting thick plate materials in various shapes.

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.