CNC Machining Teflon

ETCN is one of the best China Teflon services for machining manufacturers, suppliers and factories. We are also a professional Pe Teflon from china manufacturer and supplier, as a specialist of valves, valvular conduits, pipe

Home » CNC Machining Teflon

Teflon CNC Machining service

♦ Teflon CNC Machining service is a high-quality and fast machining process. Teflon CNC Machining uses a special tool to remove material from a part. The tool used in this process is made of tungsten carbide, which can be changed according to the shape of the part. This technique increases the accuracy of the finished product and reduces costs by minimizing waste.

♦ Teflon CNC Machining is used in various aerospace, automotive, and medical industries. This process can be used to make parts with complex geometries that cannot be produced by other machining methods, such as turning or milling. It is also used for high-volume production runs because it can quickly produce large amounts of parts without sacrificing the quality or precision of each piece.

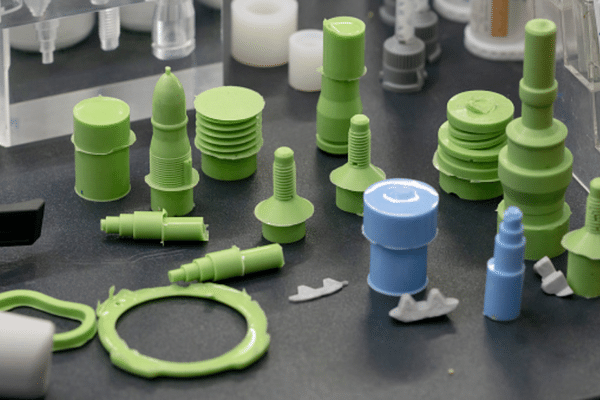

custom teflon parts

Teflon Parts are made for a variety of applications, including:

- Casting molds

- Prototype parts

- Investment casting

- Injection molding

Custom Teflon Parts are manufactured with advanced materials and processes that allow us to create the most durable, functional, and cost-effective components possible. We offer Teflon parts in a wide range of sizes and materials, including:

- PTFE (polytetrafluoroethylene) film, tape, and sheet

- Silicone rubber film, tape, and sheet

- Urethane film, tape, and sheet

turning teflon

Turning Teflon is a process of turning the polymer into a powder. It is most commonly used to create Teflon powder but can also create another polytetrafluoroethylene (PTFE) powders.

Teflon powder is used in many industries and applications, including:

- Paint and coating industry. The Teflon powder can be added to paint and coating formulas to help with gloss, hardness, and durability.

- Aerospace industry. Teflon powder is often used as a release agent in aerospace manufacturing. It allows parts to be easily removed from molds or other tools without damaging them or creating static electricity buildup that could cause an explosion.

- Medical industry. Teflon powder can be used as a coating on implants such as pacemakers and artificial joints, so they don’t irritate the body; it’s also used as a lubricant when removing foreign objects from the body, like bullets or shrapnel fragments.

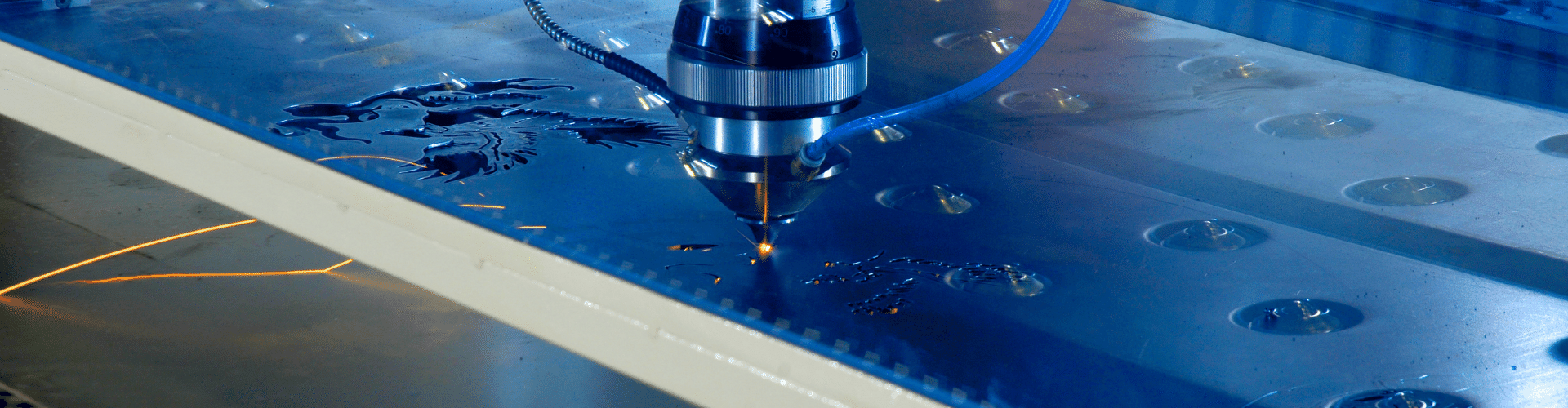

Machining Teflon

♦ Teflon milling is a material removal process that uses abrasive particles to remove material from a surface. It is used in machining applications where the material to be removed is relatively soft, such as aluminum, copper, or plastic.

♦ Teflon milling works using a rotating abrasive disk coated with Teflon particles. The disk spins against the machined material, removing small pieces of material each time. Because the Teflon particles are very durable and resistant to heat, they can be reused many times without wearing them out. The size of the removed pieces depends on how much pressure you put on the machine during use.

Teflon Parts Manufacturers

ETCN is a manufacturer, supplier, exporter, and trader of various types of Teflon Parts. Teflon Parts are widely used in various industries such as aerospace engineering, automotive engineering, medical equipment, etc. These parts are manufactured using top-notch raw materials to meet international quality standards. We offer these parts at highly competitive prices to our customers.

Our product range includes:

- Teflon Pipes

- Teflon Valves

- Teflon Fittings

- Teflon Capsules

- Teflon Tubing etc

Teflon Machining Tips

#1 Use very sharp cutting tools

This is one of the most important tips when machining Teflon. Using dull cutting tools will damage the material and make it more difficult to achieve the desired tolerances. Make sure to use freshly sharpened tools whenever possible.

#2 Apply liberal amounts of water-soluble coolant

This will help to cool the cutting tools and prevent them from damaging the Teflon material. It’s important to use a water-soluble coolant so that it can be easily removed after machining is complete.

#3 Aim for medium-to-loose tolerance

- Teflon is not as easy to machine as other materials, so it’s important to set your tolerances accordingly.

- Trying to achieve too tight of tolerance will likely result in damaged parts and frustration.

- A good rule of thumb is to aim for tolerances twice as loose as what you would normally use for other materials.

#4 Plan a deburring strategy

- Deburring Teflon can be tricky because the material is so soft.

- It’s important to have a plan before starting machining so that you don’t damage the parts you’re working on.

- One deburring method often works well is using a rotary tool with a soft brush attachment.

Teflon is a unique material that requires special care when machining. By following these tips, you’ll be able to successfully machine Teflon parts without damaging them.

Why Choose ETCN CNC PTFE/Teflon Machining?

♦ Professional and cost-effective service.

ETCN is a professional company leading the industry in producing high-precision PTFE/Teflon products and components. We have been making parts for many years, so we understand your needs and desires. We also provide you with an optimal solution to ensure your success in the market.

♦ Competitive prices.

We offer competitive prices based on our products’ quality and low overhead costs. This allows us to offer you great value for your money while maintaining profitability.

♦ Excellent quality control system.

We use state-of-the-art CNC machines, which our experienced engineers strictly control during every stage of production to ensure high-quality standards are always met. Our QC team checks each product before shipment to ensure they meet all safety requirements and specifications set forth by customers worldwide while also ensuring that they meet international environmental regulations! Many companies have trusted us with their manufacturing needs over the years!

The definitive guide to Machining Teflon

Material Properties Of Teflon PTFE

Teflon PTFE is a brand name for polytetrafluoroethylene (PTFE). It has a melting point of 327°F. It is useful in applications that require high heat resistance, excellent chemical resistance, and good electrical properties.

Teflon PTFE is a synthetic base polymer in cookware coatings because it can be used at high temperatures without releasing toxic fumes. The fluoropolymer also has a low friction coefficient, which means it does not easily stick to other surfaces.

It is often used in producing semiconductors, including computer chips and transistors. The material’s low coefficient of friction makes it ideal for an electrical insulator. Teflon PTFE also has a high-temperature tolerance, which makes it suitable for use in engines and other machines that must operate under extreme conditions.CNC machining ABS plastic.

Precautions For CNC Machining PTFE

Teflon PTFE is a low-friction material and can be machined with ease. However, some precautions must be taken into account when machining this material.

1. When CNC machining PTFE Teflon, remember that the material has very little thermal expansion, so do not apply too much force on it as it may cause damage to the tool.

2. The surface of CNC Machining PTFE chips is easy, so it is important to use sharp tools and maintain them properly so that they can cut through the material without any problems.

3. There are many different grades of PTFE available, and each has different characteristics that need to be considered before machining any part from this material.

Advantages of CNC machining Teflon parts

The main advantage of Teflon machining parts is the ability to make complex shapes, which cannot be achieved with other methods.

The second advantage is that it can produce high-quality products with a minimum amount of waste.

The third advantag is that it is possible to manufacture parts with different materials (including plastics and metals) in one batch.

The fourth advantage is that it allows you to create multi-component parts.

The fifth advantage of that it allows you to use expensive materials without fear of losing them during the process because they are automatically replaced by another material when needed.

Should I pay attention to stress creep properties when machining teflon?

The material characteristics of Teflon are very similar to those of steel and other metals. For example, the elastic modulus is about 20 times higher than steel’s and its yield strength is much lower than that of steel.

The low yield stress means that if you cut too much material away in one pass, you will cause over-stress and cracking in the material. It is better to break down the job into smaller pieces so that the part does not have to support its own weight on one edge or corner. The stress creep rate at room temperature is about 1/2% per hour (ASTM D 638). It is possible that under some conditions your parts could develop stress cracks due to this creep effect after they have been machined and assembled into an assembly which is under load.

Precautions for plastic machining

Tight machining tolerances are required because plastics expand when heated and contract when cooled. This means that if you try and cut plastic that has been heated too high or cooled too low, you could end up with gaps between parts after assembly.

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.

Blogs about Machining Teflon/PTFE

Need quality cnc machining service in China

As a full-service precision machining house, ETCN has been offering CNC machining to customers with precision machining and high quality service.