CNC Turning China

ETCN is one of the best china CNC turning factories. Our company has garnered a high reputation in the industry for its quality and service. We offer our customers a specialized range of products of CNC turning china and welcome contact from businesses

Home » CNC turning china

Introduction to CNC Turning China & ETCN

When looking for a quality CNC turning service, it is important to consider ETCN’s capabilities. ETCN has the latest technology and equipment to provide the highest quality services possible. Additionally, ETCN offers a wide range of turn options to fit your specific needs

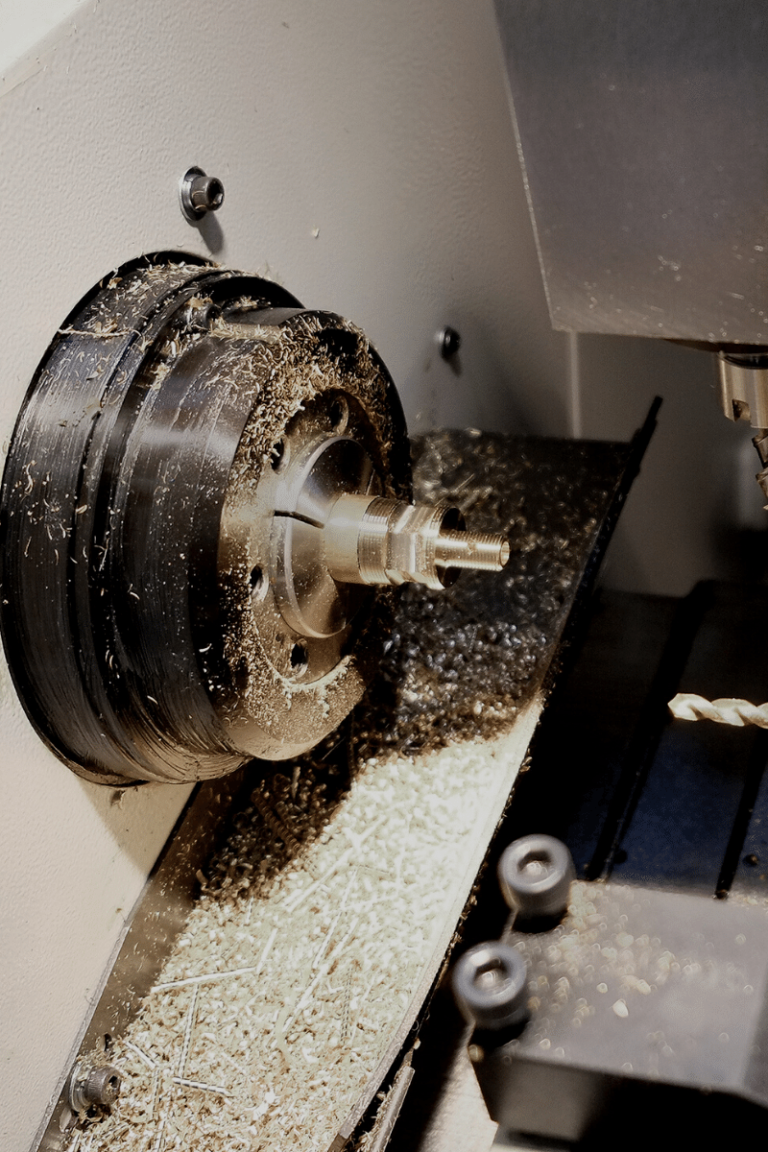

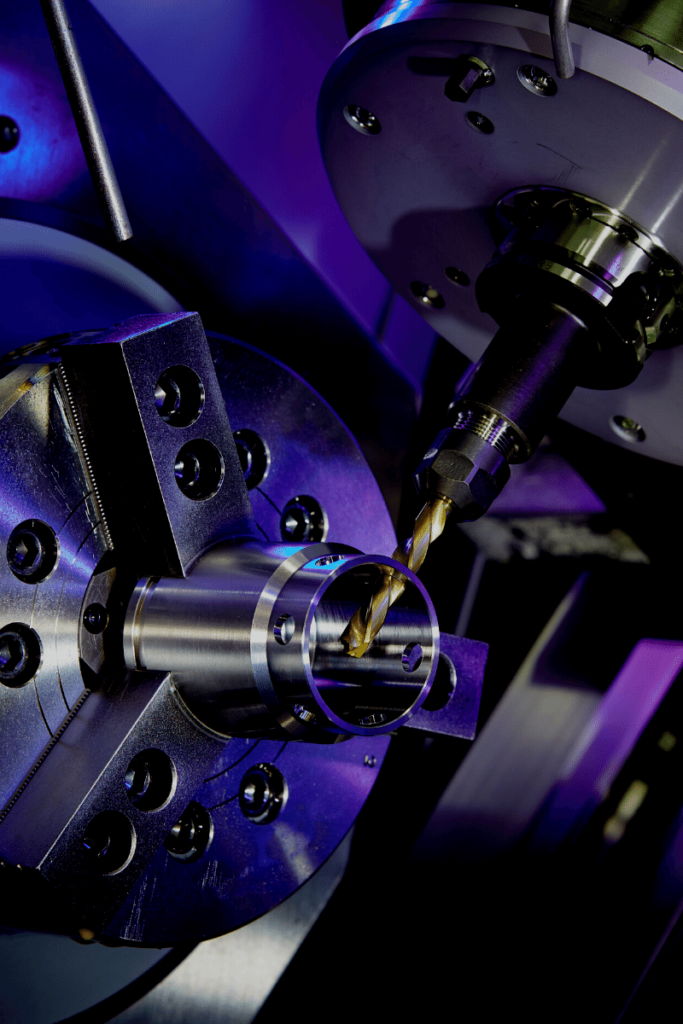

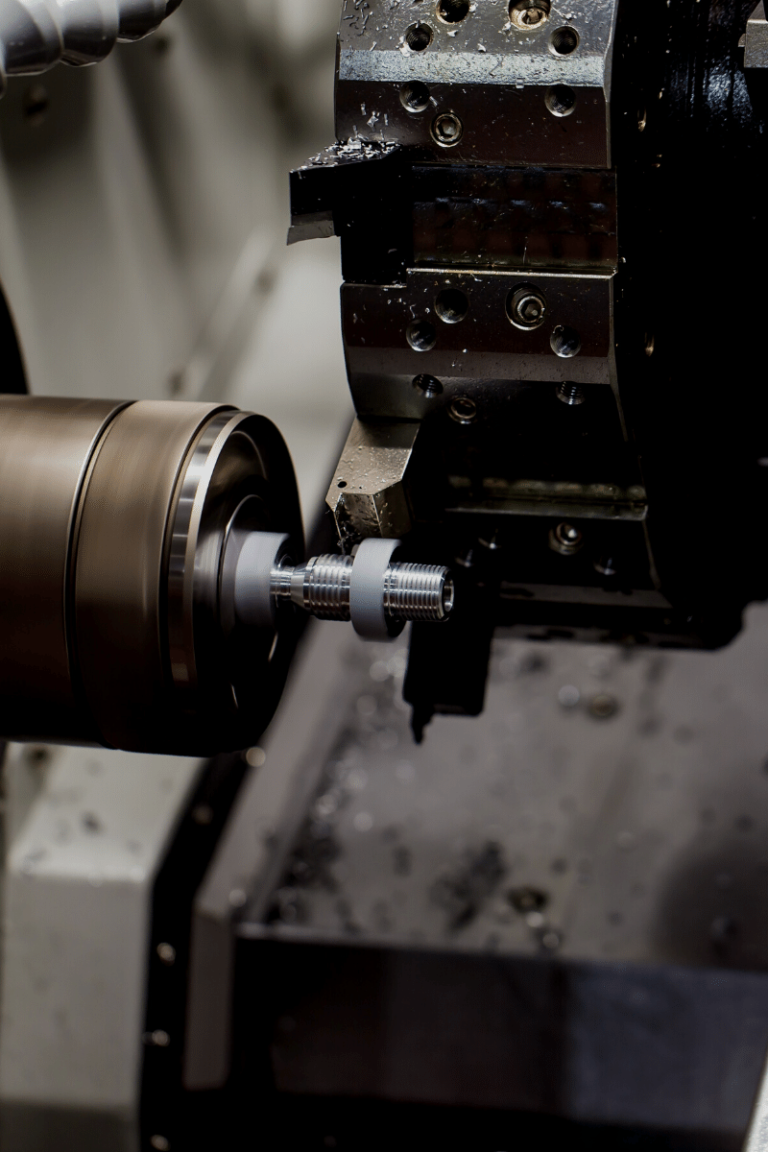

With precise control of cutting and milling on a CNC lathe, the parts processed have the characteristics of stability and high precision. CNC turning is a manufacturing process that uses computer numerically controlled (CNC) tools to create parts from a model. The process uses three-dimensional models created by computer-aided design software (CAD) programs. The models are then turned into metal parts using machines with high levels of accuracy and precision

ETCN at CNC turning China the advantages

With precise control of cutting and milling on a CNC lathe, the parts processed have the characteristics of stability and high precision. This is why we are one of the most popular china CNC turning factories. Our company has more than 10 years of experience in manufacturing CNC lathes, which can meet all kinds of requirements from domestic or foreign customers. We also provide complete after-sales services for all machines we sell, so that our customers can obtain higher profits with good quality products

ETCN is China's leading premium CNC turning service

When looking for a quality CNC turning service, it is essential to consider ETCN’s capabilities. ETCN has the latest technology and equipment to provide the highest quality services possible. Additionally, ETCN offers a wide range of turn options to fit your specific needs

With precise control of cutting and milling on a CNC lathe, the parts processed have the characteristics of stability and high precision. This is because everything from material selection to tooling is carefully considered before beginning production.

The process begins with the selection of materials that meet your specifications for hardness, density, strength, and other properties. Once chosen, these materials are cut into pieces that are then milled into their final shape.

At this point, each piece undergoes a series of tests to ensure it meets all requirements set forth by our customers. These tests include:

Visual inspection: Each part will be visually inspected by one or more people in order to ensure its quality before going on further testing procedures

Benefits Of CNC Turning

Highly Repeatable Solutions – Achieving high levels of accuracy and repeatability is essential in any manufacturing environment, especially when you are dealing with complex geometries or materials with tight tolerances. With the ability to simplify multi-axis processes into one single motion, multi-axis CNC turning centers can dramatically increase throughput while reducing costs associated with setup time and tool changes.

Materials Used for CNC Turning Services

We have a comprehensive range of CNC turning services to help you achieve the best possible results. Our advanced CNC turning center routinely works with a wide variety of materials, ranging from copper, brass, stainless steel, carbon steel, aluminum, and titanium. We can always choose a suitable precision turning process to reach your requirements. The following is a list of common materials used by CNC turning manufacturers:

Aluminum: Aluminum 2024, Aluminum 5052, Aluminum 5083, and so on.

Copper: Copper C110, Copper 101, and so on.

Steel: Alloy Steel 4130, Alloy Steel 4140, Mild Steel 1018, and so on.

What parts are suitable for CNC turning?

There are many parts that can benefit from CNC turning, but there are a few that really shine. Here are some of the best:

⦁ Precision parts with high precision requirements

⦁ Parts with special threads

⦁ Parts with complex surface shapes

⦁ Ultra-precision and ultra-low surface roughness parts

⦁ Parts with lateral machining