CNC Machining Brass from china

ETCN offers high accuracy CNC machining brass metal, supplier of CNC machining brass, CNC machining parts

Home » Complete Guide to CNC Machining » CNC Machining Brass

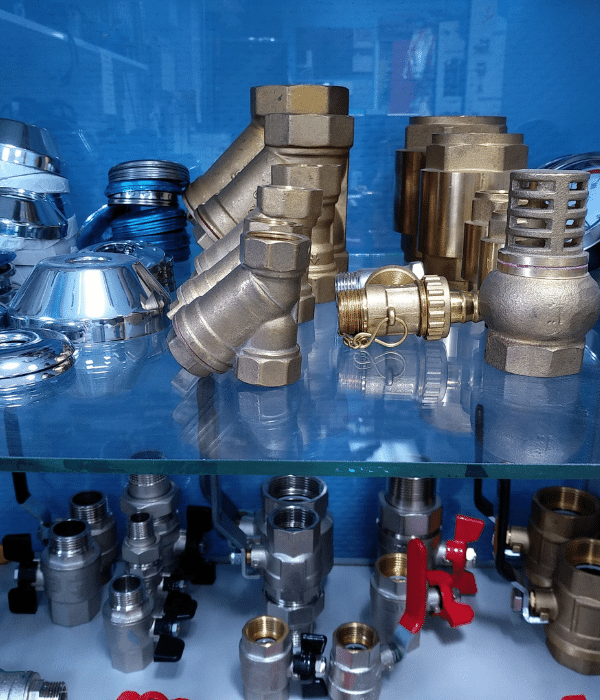

CNC Machining Brass Parts

♦CNC machining brass parts is a process that can be done by companies that specialize in machining. The process is a combination of machining, lathing, and turning.

♦CNC machining uses computer numerical control to cut the brass material precisely.

♦Brass is an alloy of copper and zinc. It is soft, malleable, and easy to work with. It has a low melting point and can be heated up easily.

♦The first step in CNC machining brass parts is cutting all the pieces out from their blanks or castings, made from solid blocks of material. The next step is to start shaping the piece, so it looks like what you want it to look like when it’s finished. This can include cutting grooves into the surface or making indentations for rivets or other elements of your design. The third step is polishing all surfaces so that they’re smooth and shiny when you’re done with your machining process and ready for assembly into your final product.

China brass part manufacturer - ETCN

Looking for precision brass parts machined by an experienced and reliable CNC components manufacturer?

ETCN is a professional manufacturer of brass parts and supplier in China. We have served the industry for over 13 years with rich experience and knowledge. Our products include brass valves, flanges, caps, plates, and so on. If you are interested in our products, please contact us. We will offer you a competitive price and good service!

Our Service:

♦1) Provide high-quality products at competitive prices.

♦2) Provide customers with professional solutions according to different requirements.

♦3) Reasonable delivery time with good service after sales.

Advantages of custom brass machining

Custom brass machining is a process that has many advantages. The most important ones are

♦1. Custom Brass Machining is Cost Efficient

It is cheaper to make customized products than mass products. This means that the production costs will be lower, reducing the product’s price.

♦2. Custom Brass Machining Provides Precision and Accuracy

When you have a customized product made, it will be manufactured with precision and accuracy, which means that it will have a very high-quality level and function properly when used for its intended purpose.

♦3. Custom Brass Machining Allows for Faster Production Times

A custom product manufacturer allows for faster production times because it can be done on demand rather than in large batches like with mass production methods.

♦4. Custom Brass Machining Can Be Used for Many Different Applications

Custom brass machining can be used for many applications such as manufacturing tools or even making jewelry items like rings and necklaces.

Best Brass Grades for CNC Machining

If you are interested in CNC machining, here is a list of the most popular materials used for your projects, along with the industries they are used in:

| Model | Common Name | Description | Advantages | Disadvantages | Applications |

|---|---|---|---|---|---|

| C230 ±85% Cu ±15% Zn <0.05 Pb | Red Brass | It is significantly stronger than yellow-gold colored brass. | Good machinability can be worked cold or hot. Excellent corrosion resistance. | Requires careful treatment and cleaning during its use and can be sensitive to corrosion under severe environments. | Architecture, jewelry, light fixtures, steam iron parts, sprinklers, and decorative parts. |

| C360 | Free Machining Brass | The zinc-copper alloy with the highest machinability. Also has excellent strength thanks to its content of lead. | Exceptional machinability, excellent strength, and good corrosion resistance. | Sensitive to acids, possible environmental impact from lead, lead content can cause a cracked surface finish in some instances. | Electrical equipment, plumbing components, screw machine parts, and musical instruments. |

| C220 ±90% Cu ±10% Zn <0.05 Pb | Commercial Bronze | Bronze-reddish colored, this brass is widely used in the architectural world. | Can be worked cold. Fair-to-good machinability relative to C360. Good ductility, strength, and hardness. Excellent corrosion resistance. | May require annealing if exposed to atmospheres that can induce stress corrosion cracking. | Architectural uses and weather-stripping. |

| C353 ±62% Cu ±36% Zn ±2% Pb + Fe | High Leaded Brass – Engravers’ Brass | Known for being both strong and wear-resistant while maintaining good machinability. | Excellent machinability (less than C360), excellent strength, corrosion, and wear resistance. | Poor to fair cold and hot working. Not ideal for welding. | Wheels, gears, valve stems, couplings, adapters, watch parts. |

| C330 ±66% Cu ±33.5% Zn ±0.5% Pb | Low Leaded Brass | A brass alloy containing relatively low amounts of lead. | Good strength, good machinability, and strong water corrosion resistance. | Difficult welding, sensitive to highly corrosive conditions (acids) | Tubing, ammunition primers, power cylinders, pumps, liners. |

| C365 ±60% Cu + Ag ±39% Zn ±1% Sn + Pb + Fe | Brass Plate / Leaded Muntz Metal | Named after George Fredrick Muntz, who commercialized the alloy following his patent in 1832. | Good machinability and excellent corrosion resistance and strength (similar to C464). | Limited cold formability, not recommended for welding. | Tube sheets for condensers and heat exchangers, baffles, support sheets. |

| C385 ±56.5% Cu ±40% Zn ±3% Pb <5% Fe | Architectural Bronze | Although it is well known as architectural bronze, this alloy is actually a brass! | Good machinability, great finishes, good corrosion resistance in non-marine conditions. | Low corrosion resistance in marine conditions, poor cold forming. | Interior applications, shower doors, bathroom partitions, fireplace lamps, valves. |

| C443 ±70% Cu ±29.85% Zn ±0.05% Sn ±0.05% Pb ±0.05% As | Admiralty Brass | Also referred to as arsenical brass, this alloy contains tin, lead, and arsenic which together provide good resistance to corrosion in brackish water and saltwater. | Excellent cold workability for forming and bending and strong corrosion resistance. | Fair to poor weldability, poor hot formability. | Condenser tubes, evaporator and heat exchanger tubes, distiller tubing in oil refineries, heater equipment. |

| C464 ±59% Cu ± 40 Zn ± 1 Sn + Pb | val Brass | Well known for its exceptional corrosion resistance thanks to the additions of tin. | Fair to good machinability compared to the C360. Excellent strength and corrosion resistance, and can be hot worked. | Prone to dezincification with time, leading to structural cracks on the surface of the alloy. | Naval applications, wear plates, fasteners, bushings, condenser tubes, and missile components. |

| C770 ±55% Cu ±27% Zn 18% Ni | German Silver / Nickel Silver | Known for its silvery appearance, yet it does not have silver at all! | Excellent electrical and thermal conductivity, high strength, excellent formability, and good corrosion resistance. | Fair machinability compared with C360, poor capacity for being formed hot. | Electronic applications, battery casings, packaging, lids, musical and ornamental applications. |

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.