Plastics Nylon

Get valuable insights on Plastics Nylon with ETCN. Discover its mechanical and physical properties and typical applications.

Details of Plastics Nylon

| Alternative Names | Mechanical Properties | Physical Properties | Thermal Properties | Electrical Properties | Post Treatments | Common Applications |

|---|---|---|---|---|---|---|

| Nylon 6 | Tensile Strength: 50-80 MPa | Density: 1.12-1.15 g/cm³ | Melting Point: 215-255°C | Dielectric Constant: 3.2-3.8 | Annealing, Stress Relieving, Drying | Automotive parts, electronic components, textiles |

| Nylon 6/6 | Tensile Strength: 80-100 MPa | Density: 1.13-1.14 g/cm³ | Melting Point: 260°C | Dielectric Constant: 3.2-3.8 | Annealing, Stress Relieving, Drying | Bearings, gears, valves, electrical insulators |

| Nylon 6/10 | Tensile Strength: 50-80 MPa | Density: 1.08-1.10 g/cm³ | Melting Point: 200-220°C | Dielectric Constant: 3.2-3.8 | Annealing, Stress Relieving, Drying | Automotive fuel systems, electrical connectors |

| Nylon 11 | Tensile Strength: 40-80 MPa | Density: 1.04-1.08 g/cm³ | Melting Point: 180-220°C | Dielectric Constant: 2.4-2.7 | Annealing, Stress Relieving, Drying | Gasoline and oil lines, pneumatic lines, cable sheaths |

| Nylon 12 | Tensile Strength: 40-60 MPa | Density: 1.01-1.03 g/cm³ | Melting Point: 170-180°C | Dielectric Constant: 2.8-3.0 | Annealing, Stress Relieving, Drying | Fuel and brake lines, hydraulic tubing, cable jacketing |

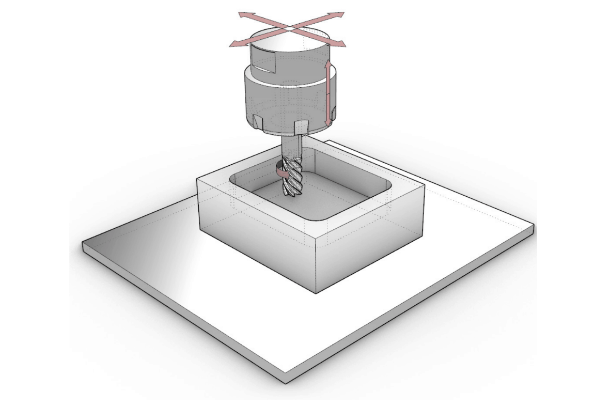

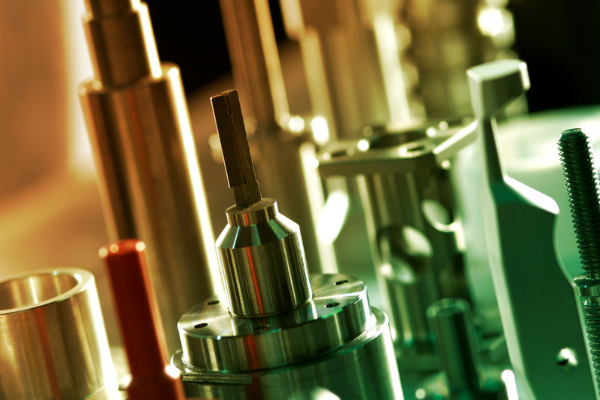

Blogs related to CNC Machining Plastics

Top 12 China CNC Machining Service Providers in 2023 You’ve...

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

Plastics Nylon: Frequently Asked Question

• Nylon plastic is widely used for a variety of applications due to its toughness, ease of manufacturing, and resistance to abrasion and chemicals.

• It is commonly used in the production of clothing, such as stockings and sportswear because of its high strength and elasticity.

• Nylon plastic is also used in the automotive industry, specifically for the development of engine components, gears, and bearings.

• The material is often used as a filament in 3D printing and is utilized in the creation of electrical and electronic components, such as cable ties, connectors, and circuit breakers.

• In addition, Nylon is used in the production of musical instruments and household items.

• Nylon plastic is generally considered to be waterproof, although its specific waterproofing properties may depend on the density and composition of the plastic.

• While some types of nylon may resist water more than others, nylon is known for its excellent durability, strength, and resistance to damage from water and other environmental factors.

• Nylon is often used in outdoor gear, such as parachutes, tents, and backpacks, due to its resistance to weather and water.

•No, Nylon plastic is not biodegradable.

•Nylon is a synthetic plastic material derived from petroleum, and it does not decompose naturally like organic matter.

•However, some companies are developing biodegradable nylon materials that break down over time under specific conditions, but they are not yet widely available.

• Nylon production involves the polymerization process, which requires the combination of a dicarboxylic acid and diamine.

• The monomers are heated to create a molten form and undergo a condensation reaction to form one long chain of polymers.

• After that, the polymer is melted and extruded, cooled, and cut into granular or pellet form.

• From there, these pellets can be molded or shaped through various production processes to create textiles, carpet fibers, and plastic parts in machines and tools.

• Nylon plastic offers exceptional strength and toughness.

• It has high tensile strength, making it able to withstand high stress and strain.

• It is resistant to abrasion, corrosion, and chemicals.

• Its strength may vary depending on its composition; different types are available with different levels of strength and durability.

• Generally, nylon plastic is renowned for its robustness and reliability in many applications.

• Nylon is a synthetic thermoplastic polymer derived from petroleum chemicals.

• It belongs to the polyamide class and is known for its strength, toughness, and abrasion resistance.

• Its unique properties include a high melting point, chemical resistance, and a lightweight structure.

• It is used to make various products such as textiles, mechanical parts, and packaging materials.