PVC Plastics

From mechanical properties to common applications, ETCN has all the information you need about PVC plastics. Check out our guide now!

Details of PVC Plastics

| PVC Plastics Properties | Values |

|---|---|

| Alternative Names | Polyvinyl chloride, vinyl |

| Mechanical Properties | High strength, good impact resistance, good flexibility, and toughness |

| Tensile Strength | 42-60 MPa |

| Yield Strength | 45-55 MPa |

| Density | 1.35-1.58 g/cm³ |

| Thermal Conductivity | 0.14-0.17 W/(m·K) |

| Electrical Conductivity | Insulator |

| Melting Point | 100-260°C |

| Post Treatments | Coating, laminating, embossing, printing, etc. |

| Common Applications | Pipes, electrical cable insulation, window profiles, flooring, medical bags, inflatable products, etc. |

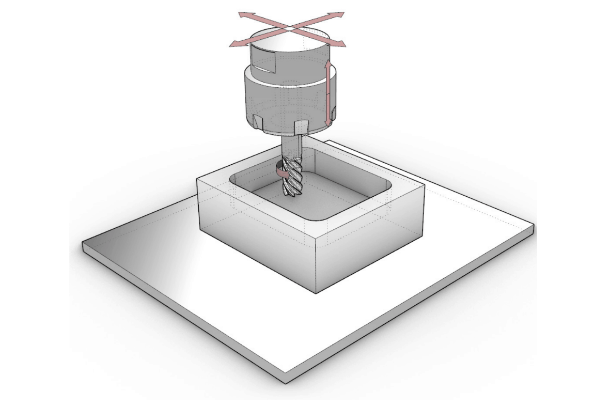

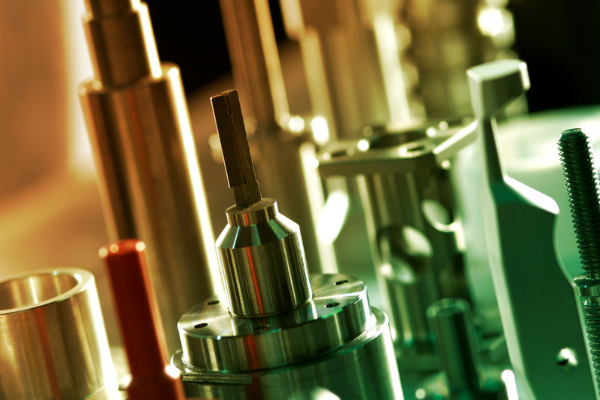

Blogs related to CNC Machining Plastics

Top 12 China CNC Machining Service Providers in 2023 You’ve...

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

PVC Plastics: Frequently Asked Question

•PVC stands for polyvinyl chloride, a synthetic plastic material made from repeating units of the vinyl chloride monomer.

•PVC plastic offers a range of desirable properties, including high durability, moisture resistance, and superior tensile strength, making it suitable for various applications.

•It is also highly resistant to chemicals, certain materials, and flame-retardant, making it an excellent choice for various industrial applications.

•Other characteristics of PVC plastic include its lightweight design, ability to be easily machined and molded into different shapes and sizes, low thermal conductivity, and its ability to retain its shape even under extreme temperatures.

•Moreover, it is inexpensive and easy to source, making it a versatile and widely used material across various industries like construction, automotive, medical, packaging, and many more.

Here are some of the common types of PVC plastics:

PVC Type I: Also known as PVC-U or uPVC, this type is a rigid and strong plastic material that is used in water pipes, window frames, and siding.

PVC Type II: This is a flexible and plasticized form of PVC that is used for making products like inflatable toys, electrical cables, and flooring.

PVC Type III: This type is a chlorinated PVC or CPVC, which has improved heat resistance compared to normal PVC. CPVC is commonly used in hot water pipes, industrial and commercial applications.

PVC Type IV: This is a rare form of PVC, known for its high molecular weight and exceptional strength. It is primarily used in making high-quality films and sheets.

PVC Type V: This type is a copolymer of vinyl chloride and vinyl acetate that is used for creating a broad range of chemical-resistant products, such as coatings, adhesives, and sealants.

PVC Type VI: Also known as PVC-P, this type features additional plasticizer content, resulting in a softer and more pliable material. It is primarily used for making medical devices, such as catheters and tubing.

PVC Type VII: This is a blend of PVC and polycarbonate, resulting in a material with enhanced durability and toughness. It is commonly used for electrical insulation, automotive parts, and sports equipment.

• PVC plastic is utilized in the construction industry due to its durability and low cost.

• It is also widely used in the manufacturing of windows, doors, and flooring materials.

• In healthcare, PVC plastic is employed in medical tubing, bags, and packaging materials.

• The material is also used to create inflatable products such as pool toys, yoga balls, and air mattresses.

• Additionally, PVC can be found in electrical wire insulation and cable jacketing due to its excellent insulation properties.

• PVC plastic is not suitable for food and beverage applications due to its potential health risks.

• Phthalates, used to soften plastic, can leach into food and may be hazardous to human health.

• Dioxins may be released during production and disposal of PVC, making it an unsustainable choice.

• To ensure safety and sustainability, choose food-grade materials such as glass, stainless steel, or silicone for food-related products.

• PVC plastic recycling involves collection, sorting, grinding, washing, and reprocessing.

• Sources of PVC waste include landfills, households, and commercial outlets.

• The waste is sorted by color and type to avoid contamination during recycling.

• The ground material is washed to remove impurities before adding the recycling compound.

• Lastly, recycled plastic pellets are used for various purposes, such as manufacturing new products and reducing environmental pollution.

• PVC plastic poses serious environmental concerns, including the release of toxic chemicals into the air, soil, and water.

• Burning or incinerating PVC plastic contributes to air pollution.

• Recycling PVC is difficult due to high costs and contamination risks.

• Most PVC plastic ends up in landfills, creating a pile-up of non-biodegradable waste.

• The production and disposal of PVC require significant energy resources, making it unsustainable.