CNC Machining Steel

ETCN’s CNC Machining Steel service produces exact, intricate parts with exceptional accuracy and consistency. All components undergo rigorous quality control procedures to ensure they meet the highest standards of excellence.

Contents of CNC Machining Steel

Are you ready to learn all about CNC Machining Steel? From the experts at ETCN, it’s time to gain essential knowledge and understanding. Let’s get started!

Discover the world of CNC machining steel with an introduction covering its definition, history, benefits, challenges, and process overview.

This topic covers materials for CNC machining steel, including types of steel, manufacturing processes, grades, characteristics, and how to select the suitable steel.

Part - 3 :CNC Machining Tools and Equipment

Learn about CNC machining tools and equipment for steel, including CNC machines, tooling, workholding devices, coolant systems, measuring devices, and milling, turning, and drilling tools.

In this topic, we'll explore CNC machining techniques for steel. This includes programming machines, cutting techniques, tapping threads, and using high-speed steel and carbide tools.

CNC Machining Steel has many applications across industries, including automotive, aerospace, precision engineering, medical device manufacturing, and construction.

Part - 6 :Post-Machining Processes for Steel

Maximizing the Results of CNC Machining Steel: A Look at Post-Machining Processes including Heat Treatment, Surface Coating, QA, and Shipping & Packaging.

Part - 1:Introduction to CNC Machining Steel

Explore the exciting realm of CNC machining steel! Delve into its definition and history, uncovering both benefits and potential challenges. Gain an overview of how this process works – all from one place!

What is CNC Machining Steel?

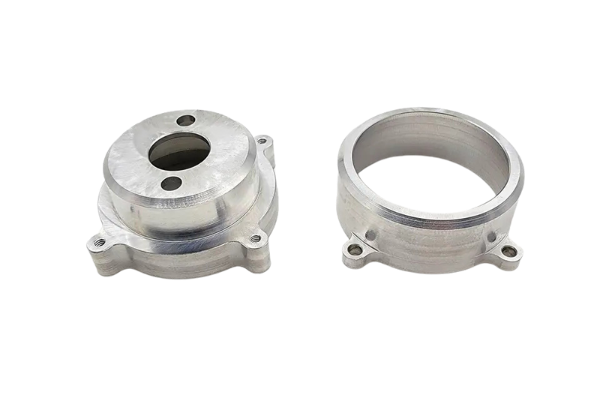

CNC Machining Steel is a manufacturing process that uses computer numerical control (CNC) machines to shape metal components with accuracy and precision. The process involves CAD files, Gcode instructions, raw material loading, and cutting shapes from steel sheets. Various tools, such as end mills and drills, are used in CNC machining to create custom-cut parts with intricate details. The quality of the machined parts depends on the type and properties of the steel being worked on, as well as program instructions that direct the machines. This technology has been applied to many industries, such as automotive and aerospace, bringing numerous benefits, including cost-efficiency, improved accuracy, increased speed, and safety.

History of CNC Machining Steel

- • CNC Machining technology was developed in the early 1970s to automate manufacturing processes and increase efficiency.

- • Initially, machinists used manual machines with limited functionalities but these were eventually replaced by numerically controlled (NC) machines that could be programmed with instructions.

- • The introduction of computer numerical control (CNC) revolutionized the industry as it allowed manufacturers to produce intricate parts of the desired accuracy with greater speed and efficiency.

- • Over the years, there have been various advancements in CNC Machining technology, from the development of more powerful software packages to highly sophisticated machines capable of complex tasks.

- • Companies such as Cincinnati Milacron and Mazak have introduced new technologies for steel manufacturing while John T. Parsons has dedicated his career towards researching and improving CNC machining techniques for steel.

- • Today, CNC Machining is a widely utilized technology in steel manufacturing due to its ability to produce superior quality parts quickly at an affordable cost.

Advantages of CNC Machining Steel

• CNC Machining Steel offers accuracy and precision, increased efficiency, cost savings, and reduced material waste compared to traditional machining methods.

• Its exceptional accuracy is ensured through computer programming and detailed CAD drawings.

• CNC machines are automated with the ability to run uninterruptedly at higher speeds, reducing production times significantly.

• Less material waste due to pre-determined shapes requirement saves money on extra stock orders.

• Applications in many industries produce high-quality products precisely tailored for particular materials.

Challenges of CNC Machining Steel

• Workpiece size and weight should be taken into account when machining steel, requiring larger machines with powerful spindles to support increased weight and precision tooling or fixtures for better accuracy.

• Material hardness and strength require specialized tools and cutting strategies, as well as heat treatment to reduce its high-temperature resistance levels prior to machining.

• Surface finish requirements depend on the process being used and the type of material, possibly requiring deburring or polishing following completion.

• Processing speed capability should be addressed by faster machines equipped with efficient software packages; safety should always be considered.

• Manufacturers must optimize processes for working with steel to maximize throughput while minimizing downtime and production costs.

CNC Machining Steel Process Overview

| CNC Machining Steel Process Overview | Description |

|---|---|

| Design | The first step is to create a 3D model of the desired part using CAD software. This model will be used to program the CNC machine. |

| Programming | The CAD model is used to generate a G-code program that tells the CNC machine what to do. This includes the tool paths, tool changes, cutting speeds, and other parameters. |

| Setup | The workpiece is secured in the CNC machine using a vise or other workholding device. The tooling is installed and the machine is calibrated to ensure accuracy. |

| Machining | The CNC machine is started and the programmed tool paths are executed. The cutting tools remove material from the workpiece to create the desired shape and dimensions. |

| Inspection | Once machining is complete, the finished part is inspected to ensure that it meets the specified tolerances and surface finish requirements. |

| Finishing | Depending on the application, the finished part may undergo additional processes such as deburring, polishing, heat treatment, or coating. |

| Packaging and Shipping | The finished part is carefully packaged and shipped to the customer, ready for use. |

Part - 2 :Materials for CNC Machining Steel

The material selection process is of utmost importance for CNC machining projects involving steel. From manufacturing processes to grades and characteristics – this topic dives into what it takes to choose a perfect type of steel suitable for your project’s needs.

Types of Steel Used for CNC Machining

| Name of Steel | Composition/Alloy | Properties | Common Applications | Advantages/Disadvantages |

|---|---|---|---|---|

| Carbon Steel | Contain up to 2% carbon | High tensile strength, good wear and tear resistance, strong, low cost, relatively hard | Automotive parts, tools, kitchen utensils, frames and structures | Low cost, good machinability and weldability. Poor corrosion resistance in most cases. Requires heat treatment for improved properties. |

| Stainless Steel | At least 11% chromium content | Good corrosion resistance and strength suitable for extreme temperatures, high levels of hardness but can be brittle at times. | Cutlery and cookware, medical instruments and equipment, construction materials. | Good corrosion resistance without the need for additional treatments or coatings (except in some cases). Can be difficult to machine because of its high hardness. |

| Tool Steel | Contains carbides such as tungsten and vanadium | Hardness up to 65 HRC (Rockwell C scale), toughness and abrasion resistance are excellent. Also known for its heat resistance properties due to the presence of microalloying elements like chromium or molybdenum | Cutting tools like drill bits or chisels as well as dies used in stamping operations | Excellent wear and tear properties along with great ductility when properly heat treated but it is usually expensive compared to other steels on the market |

| Aluminum Alloys | Contain 3-5% silicon plus copper and magnesium | Structural components like screws or housing parts used in consumer electronics appliances as well as aerospace industry components due to its light weight plus high strength-to-weight ratio |

Steel Manufacturing Process

• Steel is essential in many industries, including construction, transportation, and manufacturing.

• Primary production involves transforming raw materials like iron ore, coal, and limestone into liquid steel using stages such as raw material preparation, roasting, and liquid steel production. Different types of steel can be produced through this method.

• Secondary production entails recycling steel scraps from industrial waste and other sources in an electric arc furnace to produce molten steel. Various kinds of steel can also be produced with this method.

• Steel manufacturing requires specialized knowledge to produce quality products that meet the needs of various industries.

Selecting the Right Steel

• Strength, durability, corrosion resistance, machinability, and hardness are key factors to consider when selecting steel for CNC machining projects.

• The machining process can have an effect on the final product’s properties, which is why it is important to select steel that can handle the stress of the process without compromising quality.

• Key questions to determine the right steel include project goals/requirements; production standards and regulations; budget; required machining tolerance; and preference for a type of steel.

• Answering these questions can lead to a successful project with an end product that meets or exceeds desired specifications.

Part - 3 :CNC Machining Tools and Equipment

Enhance your knowledge of CNC machining and discover the machines, tools, and systems used to shape steel. From workholding devices to drilling technologies and coolant systems – explore all that’s needed for successful metalworking!

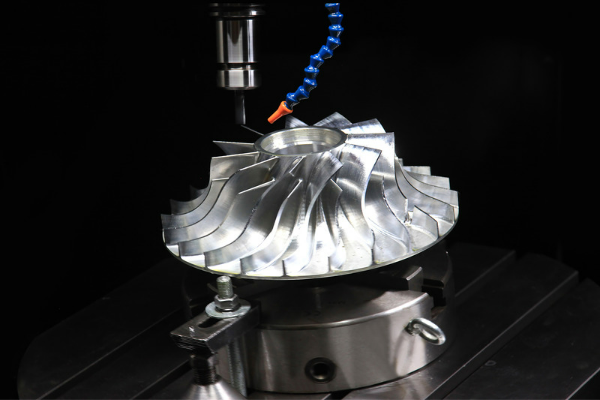

CNC Machines for Steel Machining

• CNC machines are ideal for steel machining due to their consistency and accuracy.

• Turning, milling, and drilling are the three main CNC machining processes used for steel machining.

• Factors to consider when choosing a CNC machine include size and capacity of the machine, tooling compatibility, cutting speed and accuracy.

• Examples of suitable machines include the Haas VF-6SS vertical machining center and DMG Mori NLX 2500 turning center.

• Careful consideration of the project’s requirements is essential to ensure high-quality parts and increased productivity.

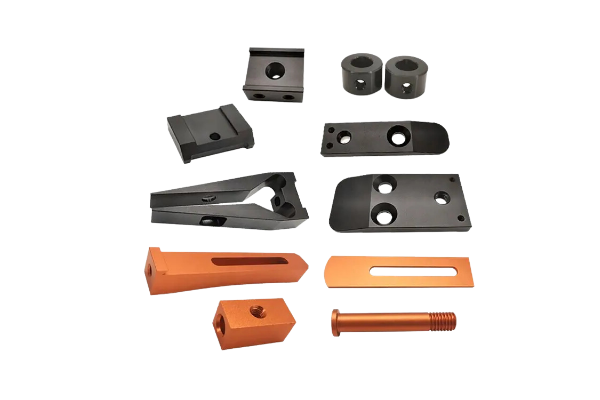

Tooling and Workholding Devices

• Tool holders are components used to hold cutting tools in place during manufacturing for accurate positioning; their geometry depends on the type of cutting tool.

• Cutting tools are used to remove material from a workpiece and come in various shapes and sizes to fit different applications.

• Workholding devices provide stability and accuracy when holding a workpiece in place during manufacturing; they include clamps, vises, and chucks.

• Proper selection and maintenance is essential for efficient and effective operations, producing quality and repeatable parts.

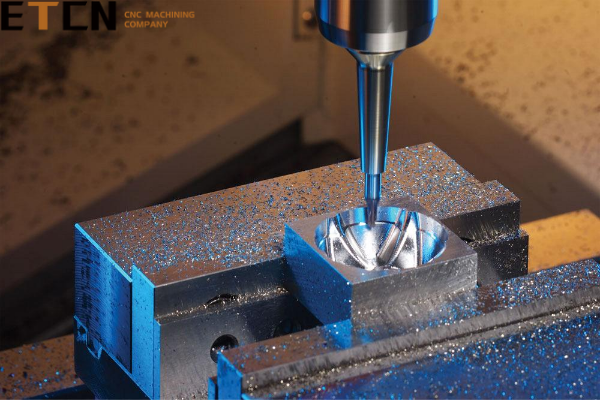

Coolant Systems and Lubricants

• Coolant systems and lubricants are vital for CNC machine operation, ensuring efficient and productive operations, as well as extended tool life.

• Different types of coolant systems and lubricants exist, each offering distinct advantages and disadvantages in terms of application, maintenance requirements, and cost.

• Quality of the coolant and lubricant used must be maintained through regular cleaning, inspection, and replacement.

• Selection of the proper coolant and lubricant is dependent on the machining process, the material being machined, and desired finished product.

• Good maintenance practices are essential to maximize the efficiency of CNC machines and minimize costs.

Measuring Devices for CNC Machining

• Measuring devices are an essential part of CNC machining, as they determine the precision of products and overall efficiency.

• Micrometers are used to measure small distances accurately and offer a high degree of accuracy and robustness.

• Vernier calipers are used to measure objects’ thickness, diameter, and depth precisely in metric and imperial units.

• Dial indicators measure the relative position of objects accurately and can be used to check for deflection or runout.

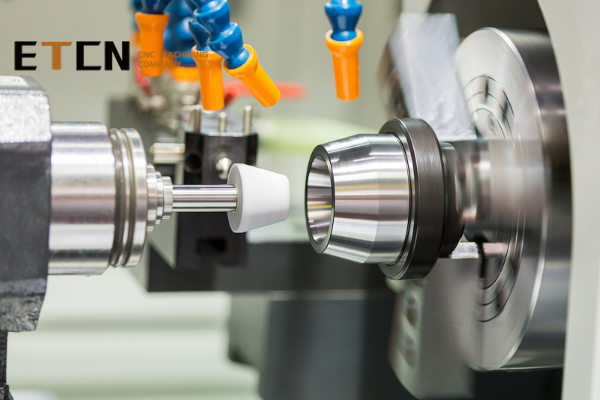

Steel Milling, Turning and Drilling

• Steel machining is a complex process that requires expertise and precision.

• Three basic steel machining processes are Milling, Turning, and Drilling. Each process has its own unique features and uses.

• To ensure successful steel machining, machine settings must be chosen to match the type of steel being machined, tooling and workholding devices should be properly used, and regular maintenance and upkeep should be conducted.

• Understanding the features of each steel machining process, selecting the right machine settings, using proper tooling and work holding devices, and regularly performing maintenance can help manufacturers produce high-quality products from steel.

Part - 4:CNC Machining Techniques for Steel

With ETCN, you can experience the ultimate in custom aluminum machining – get a product tailored to your exact specifications with top-of-the-line quality and unbeatable benefits.

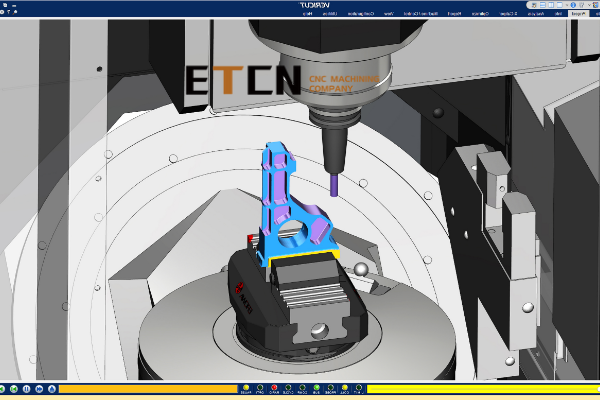

Programming CNC Machines for Steel Machining

• Understanding G-code and M-code is essential for programming CNC machines for steel machining.

• Choosing the right tool path and machining strategy is key to achieving desired shape and size for a steel part.

• Optimizing tool changes and feed rates can improve efficiency and accuracy and reduce tool wear.

• Pre-processing best practices, such as simulation software, can help identify errors in the tool path and selection.

• Regular maintenance and calibration are essential to optimize the machine’s performance and tooling.

| Process of Programming CNC Machines for Steel Machining | ||||

|---|---|---|---|---|

| Types of Materials Used in Machining Process | Commonly Used CNC Machines | Required Cutting Tools and Inserts | Cutting Parameters (Feed Rate, Spindle Speed, Depth of Cut, & Cutting Speed) | Post-Processing Routines & Quality Checks |

| Mild Steel/Carbon Steel | Vertical Mill | End Mills | Varies Depending on Material Hardness & Tool Material; Approx. 100-200 m/min for Mild Steel or Carbon Steel | Mechanical Polishing; Surface Inspection |

| Tool Steel | Lathe | Reamers | Varies Depending on Material Hardness & Tool Material; Approx. 50-100 m/min for Tool Steel | Lapping; Chemical Polishing |

| Stainless Steel | Drill | Taps | Varies Depending on Material Hardness & Tool Material; Approx. 25-60 m/min for Stainless Steel | Ultrasonic Cleaning; Visual Inspection |

Machining Speeds, Feeds, and Surface Finishing

• Machining processes involve cutting, shaping or removing materials from workpieces to create a specific shape or size.

• Variables that affect machining speeds and feeds include the type of machining process and material being machined.

• Surface finishing is achieved through cutting parameters and tool selection, with depth of cut, feed rate, and cutting speed all playing a part.

• Common mistakes that lead to surface defects include tool wear, incorrect tool geometry, poor fixturing, and improper coolant systems.

• By adopting a methodical and precise approach, manufacturing engineers can optimize their machining parameters, select the right tools, and avoid costly mistakes.

| Material | Optimal Speed & Feed | Depth of Cut | Best Method for Surface Finish | Recommended Tools & Equipment | Safety Precautions |

|---|---|---|---|---|---|

| Mild Steel/Carbon Steel | 100-200 m/min, 0.05 mm/rev (approx.) | Varies Depending on Material Hardness | Mechanical Polishing; Chemical Polishing | End Mills; Reamers; Drills; Taps; Slotting Cutters | Wear Personal Protective Equipment; Take Regular Tool Breaks |

| Tool Steel | 50-100 m/min, 0.02 mm/rev (approx.) | Varies Depending on Material Hardness | Lapping; Honing | Reamers; Taps; Slotting Cutters | Wear Eye Protection and Gloves |

| Stainless Steel | 25-60 m/min, 0.01 mm/rev (approx.) | Varies Depending on Material Hardness |

Tapping Threads in Steel

• Tapping threads in steel is a process used for manufacturing, repair, and maintenance projects that involve screw connections.

• Knowing the different types of threads (metric or unified) and tap geometry (flutes, chamfers, thread lead, and thread profile) helps with selecting the right tap for a job.

• Types of taps include hand taps and machine taps.

• Best practices include lubricating the tap and cleaning chips regularly to prevent broken taps; additionally, manually aligned taps should be used with caution.

| Aspect | Information |

|---|---|

| Types of threads commonly used in steel tapping | Metric, Imperial, Unified, ACME, NPT |

| Size range of threads that can be created through tapping | From 6-32 UNC (M3 x 0.5) up to 2-1/2" NPT (64mm) |

| Related drill sizes for tapping | Based on the thread size, a pre-existing hole size needs to be drilled, usually about 80%-85% of the final thread size |

| Cutting tools and materials commonly used | High-speed steel (HSS) taps, carbide-tipped taps, coatings (TiN and TiCN) to improve tool life, tapping oil or paste for lubrication, spindle oil or soluble oil |

| Essential tapping procedures | Step 1: Pre-tapping (drilling a hole), Step 2: Aligning the tap, Step 3: Cutting speed (generally slower than drilling), Step 4: Tapping oiling (ensures a smooth and accurate cut), Step 5: Thread finishing (use of dies, chamfering tools, or sandpaper) |

| Tips for troubleshooting common tapping issues | Tool breakage (use lubricant, reduce speed, use a harder tool), thread stripping (check alignment, use a stronger tap, reduce speed), proper hole sizing and tapping depth. |

Part - 5 :Applications and Industries using CNC Machining Steel

CNC Machining Steel is an integral part of many industries, from the production of automobiles and aircraft to precision engineering and medical device manufacturing. Its diverse uses make it a staple in construction projects worldwide.

Applications and Industries using CNC Machining Steel

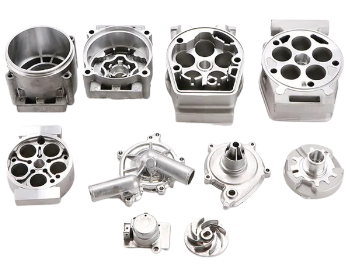

• Automotive Industry: CNC machining is used to produce components such as engine cylinders and braking systems, leading to improved performance and durability of vehicles.

• Aerospace Industry: CNC machining is used to produce turbine blades, jet engine parts, and aircraft frames which require high accuracy and tolerance.

• Precision Engineering Industry: CNC machining produces components such as gears, bearings, and sealing components with high accuracy.

• Medical Device Manufacturing Industry: CNC machining is used for the production of surgical instruments, prosthetics, and implants with extreme precision.

• Construction & Infrastructure Industry: CNC machining is used for the production of steel components such as beams and trusses that are used in construction of large structures.

• Advantages of Using CNC Machining in Steel Production: Improved performance and safety, complex geometries achievable, reduced lead times for increased efficiency.

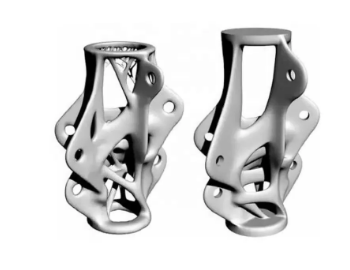

• Future of CNC Machining in Steel-based Products: Machine learning algorithms to improve accuracy/efficiency; use of multi-axis machines; potential disruption from 3D printing technology.

| Industry | Specific Applications |

|---|---|

| Automotive | Engine components, transmission components, suspension components, brake components, steering components, and exhaust systems are all made of CNC Machining Steel. |

| Aerospace | CNC Machining Steel is used in the manufacture of aircraft structural components, engines, and landing gear. It is also used in the manufacture of spacecraft, especially those designed for atmospheric re-entry. |

| Precision Engineering | CNC Machining Steel is used in manufacturing a wide range of products and components. Examples include gears, bearings, fasteners, control valves, actuators, and pumps. |

| Medical Device Manufacturing | CNC Machining Steel is used in medical device manufacturing to create implants, surgical instruments, and diagnostic tools. Additionally, it is used in the creation of medical devices such as pacemakers and insulin pumps. |

| Construction and Infrastructure | CNC Machining Steel is used in the construction industry to construct bridges, buildings, and other infrastructure projects. It's used for beams, columns, rebar, and other structural components. |

Part - 6 :Post-Machining Processes for Steel

To ensure the highest-quality results from CNC machining steel, ETCN should take into account not only prior steps in the production process but also post-machining practices such as heat treatment, surface coating for corrosion protection and aesthetic enhancement, comprehensive quality assurance measures to guarantee conformance with standards & tolerances, along with secure shipping packaging.

Post-Machining Processes for Steel

• Deburring and polishing help remove any rough edges or burrs that may occur during machining, but it is crucial to ensure this process is done correctly as it impacts the overall quality and accuracy of the machined part.

• Heat treatment is another essential post-machining step involved in altering the physical properties of steel. Different heat treatment methods such as annealing, quenching, and tempering are used based on the desired properties of the steel.

• Surface coating and plating involve applying a protective layer to enhance the functional properties of machined parts.

• Quality assurance and control processes involve inspection, testing, and verification to guarantee the part meets specifications and standards.

• Shipping and packaging ensure that the machined parts are appropriately packaged and protected during customer transportation.

| Post-Machining Process | Explanation | Variables | Safety Precautions |

|---|---|---|---|

| Grinding | Uses abrasive wheels to remove material and improve surface finish | Wheel material, wheel speed, depth of cut, coolant flow rate | Wear appropriate personal protective equipment (PPE), ensure proper grounding of equipment, follow lockout/tagout procedures |

| Polishing | Uses abrasive compounds to remove minor surface imperfections and improve surface finish | Abrasive compound type, wheel speed, pressure applied, polishing time | Use caution when handling abrasive compounds, ensure proper ventilation when using chemical polishing agents |

| Deburring | Removes sharp edges and burrs left from the machining process | Deburring tool type, feed rate, depth of cut, coolant flow rate | Wear appropriate PPE, ensure proper grounding of equipment, follow lockout/tagout procedures |

| Heat Treatment | Alters the properties of steel by heating and cooling to specific temperatures | Temperature, time, heating and cooling rate, quenching medium | Use caution when handling hot materials, follow proper heat treating procedures and safety guidelines |

| Shot Peening | Bombards steel with small metal or ceramic particles to increase strength and improve fatigue life | Shot size and material, shot velocity, shot coverage area, shot peening time | Wear appropriate PPE, ensure proper containment and disposal of shot media, follow safety guidelines for shot peening equipment |

| Electroplating | Deposits a layer of metal onto the steel surface to improve corrosion resistance or aesthetics | Plating material, plating thickness, plating method, plating time | Follow proper safety guidelines for handling plating chemicals, ensure proper ventilation and PPE when working with plating equipment |