Stainless Steel 17-4PH

Discover everything you need to know about ‘Stainless Steel 17-4PH’ with ETCN. Click here for exclusive information and expert insights!

Details of Stainless Steel 17-4PH

| Name of Steel | Stainless Steel 17-4PH |

|---|---|

| Alternative Names | UNS S17400, AISI 630, ASTM A693 Grade 630, AMS 5604, AMS 5622, AMS 5643 |

| Composition/Alloy | Chromium 15-17.5%, Nickel 3-5%, Copper 3-5%, Manganese 1%, Silicon 1%, Columbium + Tantalum 0.15-0.45%, Phosphorus 0.04%, Sulfur 0.03%, Iron balance |

| Mechanical Properties | |

| - Tensile Strength | 1100 MPa (160,000 psi) |

| - Yield Strength | 1035 MPa (150,000 psi) |

| - Elongation at Break | 5% |

| - Hardness (Rockwell C) | 38 |

| Physical Properties | |

| - Density | 7.75 g/cm³ |

| - Melting Point | 1399-1454 °C (2550-2650 °F) |

| - Thermal Conductivity | 16.3 W/m·K at 100°C |

| - Specific Heat Capacity | 0.460 J/g·K |

| Thermal Properties | |

| - Coefficient of Thermal Expansion | 10.8 µm/m·K |

| - Thermal Conductivity | 16.3 W/m·K at 100°C |

| Electrical Properties | |

| - Electrical Conductivity | 0.26 × 10^6 S/m |

| Post Treatments | Solution annealing, precipitation hardening, aging, stress relieving |

| Common Applications | Aerospace components, chemical processing equipment, food processing equipment, medical devices, nuclear waste processing, oil and gas industry, paper mills, power generation equipment |

| Advantages/Disadvantages | High strength and hardness, excellent corrosion resistance, good toughness and ductility, magnetic in hardened condition, lower machinability compared to some other stainless steel grades, susceptible to stress corrosion cracking and hydrogen embrittlement |

Blogs related to Stainless Steel Machining

Top 12 China CNC Machining Service Providers in 2023 You’ve...

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

Stainless Steel 17-4PH: Frequently Asked Question

• 17-4PH is a precipitation-hardening martensitic stainless steel alloy with superior corrosion and strength properties.

• It contains 15-17.5% chromium, 3-5% nickel, 3-5% copper and 1% manganese for unique characteristics.

• It can be hardened by a simple one-step aging treatment at 900-1150°F (425-615°C).

• High tensile strength and fatigue limit make it suitable for durable products.

• Corrosion resistance gives it up to 5 times longer lifespan compared to conventional materials.

• Low maintenance costs due to long-term use capabilities.

• Stainless steel 17-4PH is an excellent material for manufacturing due to its superior corrosion resistance and high tensile strength, making it ideal for applications in extreme environments or precision equipment.

• Its anti-corrosion features make it environmentally friendly.

• However, its resistance to carburization can be compromised with extended exposure to higher temperatures, while weld decay may occur in moderate temperature conditions.

• Additionally, the alloy may be more expensive than other materials due to its special heat treatment process.

• It offers corrosion resistance, superior wear resistance, higher durability, and good formability.

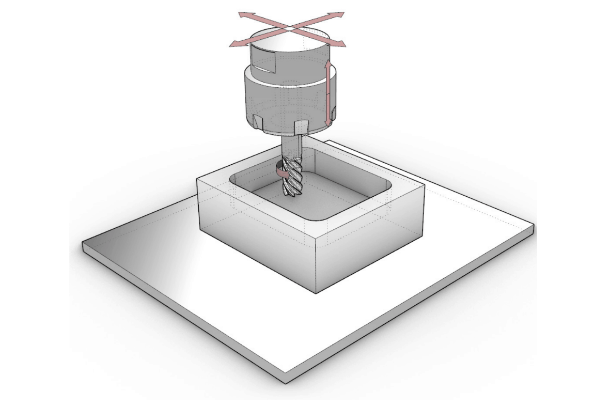

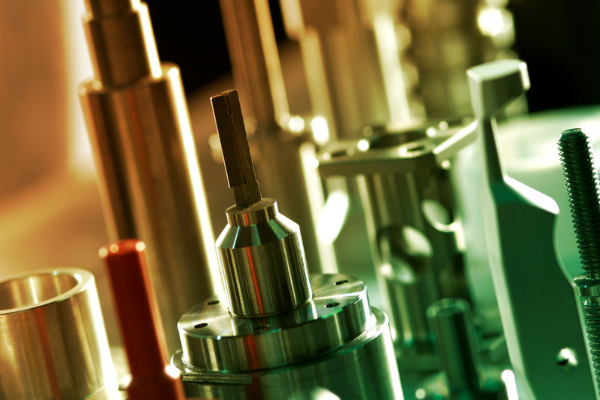

• It can be machined by cold sawing, grinding heat-treating, EDM (Electrical Discharge Machining), or Turning. It can also be welded using TIG welding techniques.

• Special tools are required for machining it; additionally, the temperature must be stabilized when welding it due to its susceptibility to thermal shock.

• Proper finishing techniques should always be implemented to maximize performance and longevity when used in harsh environments.

• 17-4PH is a precipitation-hardened stainless steel composed of iron, chromium, nickel, carbon, and manganese, known for its exceptional strength and hardness.

• It has superior resistance to stress corrosion cracking, making it suitable for heavy-duty applications.

• Due to its higher alloy content, 17-4PH achieves its maximum hardness when heat treated between 400°C-600°C whereas other stainless steels do not require this additional step in order to achieve their maximum hardness. This makes 17-4PH suitable for manufacturing components that require a very hard surface, such as aerospace parts or medical tools.

• Its composition can include added elements such as titanium or copper to increase wear resistance further.

• Its properties make it an optimal choice for oil & gas, food services & processing equipment, automotive parts manufacturing, and extreme environment-demanding applications.

• Stainless steel 17-4PH is an exceptional material for construction due to its impressive strength and endurance limit, with a tensile strength of 1100Mpa and a Yield Strength of 1035 Mpa.

• Its properties can be improved through heat treatment processes such as aging, solution treating, and precipitation hardening, which can cause up to 30% increase in hardness and improved corrosion resistance.

• Obtains different Rockwell C hardness values depending on heat treatment processes, generally ranging from 35-45; offers greater wear resistance and durability in industrial applications.

• Offers numerous benefits for construction over other materials due to its excellent corrosion resistance properties; suitable for many industries due to its ability to obtain various levels of hardness.

• Hinderer chose to use stainless steel 17-4PH for the nibs of their pens due to its excellent wear and corrosion resistance properties.

• The high hardness level (up to 45 on the Rockwell C scale) achieved when subjected to heat treatment processes makes it much more durable than other commonly used metals in pen nib manufacturing, such as brass or aluminum alloys.

• Additionally, it offers superior corrosion resistance, which ensures that the nib will remain in pristine condition for many years of use without being affected by moisture or other external factors.