Titanium Grade 5 (Ti-6Al-4V)

Interested in learning more about Titanium Grade 5? ETCN’s got you covered with all the info needed to make informed decisions!

Details of Titanium Ti-6al-4v (Grade 5)

| Name of Titanium | Titanium Ti-6al-4v (Grade 5) |

|---|---|

| Alternative Names | Ti-6Al-4V, UNS R56400, Grade 5 titanium alloy |

| Composition/Alloy | Aluminum 5.5-6.75%, Vanadium 3.5-4.5%, Iron max 0.30%, Oxygen max 0.25%, Carbon max 0.08%, Nitrogen max 0.05%, Hydrogen max 0.0125%, Titanium balance |

| Mechanical Properties | |

| - Tensile Strength | 880 MPa (128,000 psi) |

| - Yield Strength | 830 MPa (120,000 psi) |

| - Elongation at Break | 14% |

| - Hardness (Rockwell C) | 36 |

| Physical Properties | |

| - Density | 4.43 g/cm³ |

| - Melting Point | 1660°C (3020°F) |

| - Thermal Conductivity | 6.7 W/m·K at 100°C |

| - Specific Heat Capacity | 0.523 J/g·K |

| Thermal Properties | |

| - Coefficient of Thermal Expansion | 8.6 µm/m·K |

| - Thermal Conductivity | 6.7 W/m·K at 100°C |

| Electrical Properties | |

| - Electrical Conductivity | 2.4 × 10^6 S/m |

| Post Treatments | Solution treating and aging, stress relieving, cold working |

| Common Applications | Aerospace components, marine equipment, medical devices, sporting goods, automotive parts |

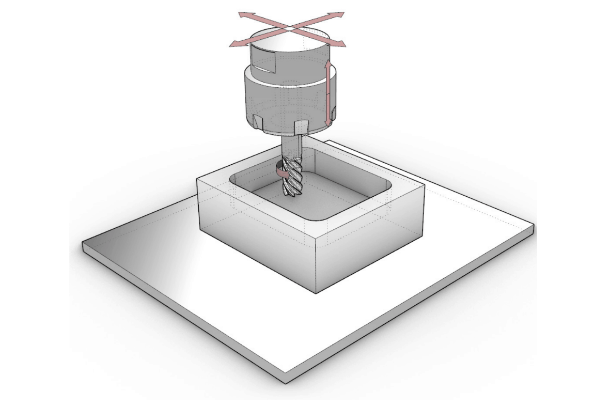

| Advantages/Disadvantages | High strength-to-weight ratio, excellent corrosion resistance, biocompatible, high temperature resistance, poor machinability, high cost compared to other titanium alloys |

Blogs related to Titanium CNC Service

Top 12 China CNC Machining Service Providers in 2023 You’ve...

For many manufacturers, CNC machining steel is crucial to producing...

Unlock the highest level of precision and longevity for machined...

CNC Machining has become an increasingly popular manufacturing solution, but...

Titanium Ti-6al-4v (Grade 5) : Frequently Asked Question

• Ti-6Al-4V is an alloy of titanium, aluminum, and vanadium combining a high strength-to-weight ratio with excellent corrosion and wear resistance making it suitable for aerospace parts, medical implants, and industrial components.

• When comparing Ti-6Al-4V to other titanium alloys, the major advantage is its increased strength due to the presence of vanadium in its composition.

• Grade 5 Titanium exhibits better performance as temperatures increase due to its higher creep resistance compared to other alloys like Ti-2O3A or CP titanium.

• On the other hand, lower density makes its thermal conductivity slower, leading to slower heat transfer rates.

• In summary, Grade 5 Titanium offers superior durability while still providing a lightweight manufacturing solution. Care should be taken when using it around elevated temperatures or near welds.

• Titanium TI-6Al-4V (Grade 5) is a specialized alloy composed of titanium, aluminum, and vanadium that offers a superior strength-to-weight ratio, making it an ideal choice for industries.

• This titanium grade has explicitly been used in the aerospace industry due to its high strength-to-weight ratio, which reduces fuel costs while increasing safety and reliability.

• It is also widely used in medical implant manufacturing due to its biocompatibility and resistance against body fluids and tissue materials.

• Other key properties include a relatively low melting point, making casting processes easier & quicker, and improved performance over lower temperatures than other titanium alloys.

• Quality Control for Titanium TI-6Al-4V (Grade 5) alloy is essential to ensure design requirements.

• Destructive testing, such as tensile and impact tests, measure the strength of the material.

• Non-destructive testing, such as radiographic and ultrasonic tests, identify material flaws or imperfections.

• Chemical composition tests ensure correct titanium, aluminum, and vanadium proportions.

• Sampling inspections during manufacturing monitor progress and identify potential defects early on.

• Visual inspections check surface finish characteristics for imperfections.

• Finish coatings or heat treatments may be necessary for additional desired characteristics.

• Final inspection procedure must be performed before delivery to meet customer requirements.

• Ti-6Al-4V (Grade 5) Titanium alloy is popular due to its excellent strength, corrosion resistance, and weldability.

• This alloy offers higher strength and better heat resistance than other titanium grades, such as Grade 2 or 4.

• its low carbon content helps reduce hot cracking during welding processes. With proper preparation techniques, such as preheating or post-weld heat treatments, it can be possible to achieve successful welds.

• Ti-6Al-4V (Grade 5) is a popular choice for manufacturing processes due to its combination of strength, corrosion resistance, and weldability. Additionally, its superior corrosion resistance makes it perfect for medical implants and other applications where the material needs to cope with extreme environmental conditions such as moisture or sulfurous gases.

• Compared to other materials, Titanium Grade 5 offers improved weldability thanks to its low carbon content. This property helps reduce hot cracking during welding processes, making production easier and faster in comparison to metals with higher carbon contents like stainless steel or Inconel.

• Due to its versatile properties, Ti-6Al-4V (Grade 5) is often chosen over other materials in various applications including aerospace, medical, military, sports and engineering sectors. Its strength and durability make it ideal for situations that require special attention in terms of performance, such as missiles or body armor; while its light weight combined with excellent corrosion resistance make this alloy perfect for use in golf clubs and bicycles. Its suitability for innovative designs makes it a desirable choice for many industries; however, specialized strategies must be employed when working with such cutting-edge materials in order to maximize efficiency while ensuring quality control standards are met during production.