Unlock the highest level of precision and longevity for machined parts with these best practices for CNC machine design. Expert tips will help you optimize part quality, saving time and materials along the way!

Design Principles for CNC Machining: The Key to Achieving Quality Results

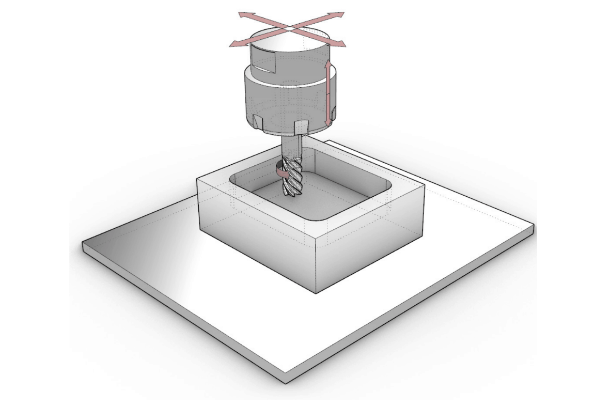

CNC machining has revolutionized the manufacturing industry by enabling precision, speed, and flexibility in the production process. However, to fully realize the benefits of CNC machining, it is essential to follow design principles that ensure adherence to manufacturing limitations, selection of appropriate materials, and control of geometry and tolerances. This article will discuss the importance of design principles in CNC machining, the principles themselves, and their benefits.

I. Introduction

CNC machining has become a standard in manufacturing due to its accuracy and speed. As such, every manufacturing company strives to get the best out of this technique. However, the solution does not lie only in acquiring state-of-the-art machines or having skilled technicians. An equally essential part of achieving quality results is designing for CNC manufacturing.

II. Design Principles for CNC Machining

A. Design for manufacturability

Design for manufacturability refers to designing products that can be easily manufactured, minimizing waste, and reducing manufacturing costs. It’s an essential principle in CNC machining since the process precision hinges on design accuracy.

Understanding manufacturing limitations

Understanding the machines’ limitations is crucial to creating a product that can be quickly and accurately manufactured. This includes tool and machine capabilities, lead times, and materials.

Minimizing waste and cost

The Design must be optimized to minimize waste while ensuring minimal material handling costs. For instance, too small features that require a lot of tool change time would make the process inefficient leading to increased manufacturing costs.

B. Material selection

Material selection is crucial, and the material of choice will affect the final product’s quality.

Characteristics of materials for CNC

The material should be selected based on its properties, including machinability, strength, thermal expansion, and heat resistance. These properties impact the ease, speed, and overall result quality of CNC machining.

Choosing the suitable material for the Design

Matching the material to the design requirements leads to significant improvements such as precision tolerances, surface finishes, and machining speeds, thus affecting the overall cost.

C. Geometry and tolerances

Accuracy in the geometric features of a product is paramount in CNC machining. Ensuring the product’s Design is within the machine’s tolerance and limited by its tools and features is essential.

Understanding geometric constraints

Critical elements contributing to accurate and precise results must be within the machine’s constraint. This includes configuring controllable geometric features, including angles and radii, ensuring smooth flow design and perfect surfaces.

Controlling tolerance for a quality finished product

Well-controlled tolerance specification ensures that design requirements are met irrespective of the machine used. This reduces rework, cost, and time invested in the production process.

III. Benefits of Design Principles for CNC Machining

A. Improved quality

Designing for CNC machining ensures precise alignment between Design and manufacturing, improving quality control and helping eliminate errors and defects.

Precise Design and manufacturing

The product’s Design and manufacturing are precise and consistent by following the design principles, ensuring the product model accuaccurately represents.

Help eliminate errors and defects.

Designing for CNC eliminates errors associated with prototyping, as CNC machining eliminates the need for post-manufacturing finishing, reducing error margins.

B. Cost savings

Design principles for CNC machining increase yields and reduce waste, leading to a more cost-effective manufacturing process.

Reducing waste and rework

Minimizing waste and rework allows CNC machining to get the most out of every production run, reducing material and machine time costs.

Helping achieve better yields and higher profitability

A design optimized for the material, the machine, and the manufacturing process increases profits from every production run, boosting revenue and profitability.

IV. Conclusion

Design principles for CNC machining play an essential role in optimizing CNC manufacturing. They help minimize waste, reduce manufacturing time, and increase product quality. By following these design principles, production costs decrease while each production’s yield and profitability increase. Therefore, every manufacturing company must follow these principles to maximize the benefits of CNC machining.

Prototype Testing and Analysis

A. Importance of Prototype Testing

Prototype testing is critical in the design process, allowing designers to catch any errors or flaws before production begins. Testing also provides valuable feedback that can be used to refine and improve the Design.

B. Types of Prototype Testing

Functional Testing

Functional testing verifies that the part or component performs as intended. This type of testing is critical to ensuring that the final product meets the desired specifications and performance requirements.

Structural Testing

Structural testing is used to verify that the part or component can withstand the intended loads and stresses. This type of testing is essential for details that will be used in critical applications.

Material Testing

Material testing ensures that the material properties meet the desired specifications. This type of testing is essential for parts exposed to extreme temperatures, pressures, or other environmental factors.

C. Tools and Methodologies for Prototype Testing and Analysis

Software Simulation

Software simulation is a powerful tool used to predict the behavior of a part or component. This type of testing can help designers identify potential problems and optimize the design before physical testing begins.

Physical Testing

Physical testing involves testing a physical prototype to validate performance and functionality. This type of testing is critical to ensuring that the final product meets the desired specifications and performance requirements.

Failure Analysis

Failure analysis determines the cause of a part or component failure. This type of testing is essential for parts that will be used in critical applications where failure could lead to significant consequences.

Designing for CNC machining and prototype testing and analysis are critical components of the design process. Considering factors such as tolerances, tool selection, and part orientation can help designers optimize their designs for CNC machining. Prototype testing and analysis provide valuable feedback that can be used to refine and improve the Design. By following the tips and methodologies outlined in this article, designers and engineers can create high-performing parts and components that meet the desired specifications and performance requirements.

Machinability and Material Selection: Essential Factors in CNC Machining

CNC machining is a continually growing industry, with its applications extending to almost every sector, from aerospace to manufacturing. With an increasing emphasis on precision and quality, selecting appropriate materials and their machinability are critical factors. Machinability refers to the ease with which a material can be machined to achieve a specific product or part.

Defining Machinability

In CNC machining, machinability is a crucial aspect in evaluating the suitability of a material for manufacturing a specific part. The machinability of a material is defined as the ease with which it can be cut, processed, or shaped without damage to the tool or the workpiece. A material with excellent machinability can be worked on with minimal effort and has a low risk of causing tool wear or damage.

Factors Affecting Machinability

Various factors contribute to the machinability of a material, including its physical and chemical properties, the tool’s geometry, and cutting parameters.

Material Properties: The physical and chemical properties of a material have a significant impact on its machinability. Materials like aluminum, copper, and mild steel are accessible to machines, while titanium and stainless steel are more challenging. Materials with high hardness, toughness, or flexibility tend to be more difficult to machine.

Tool Geometry: The geometry of the tool used in machining also affects the machinability of a material. Tool geometry considers factors like rake angle, clearance angle, and cutting edge radius, among others. These factors determine the degree to which the tool penetrates the material, the chip formation, and the force required to cut the fabric.

Cutting Parameters: Cutting parameters include factors like cutting speed, feed rate, and depth of cut. Adjusting these factors can improve or reduce the machinability of a material significantly. Some materials may require higher cutting speeds or feed rates for optimal machinability.

Importance of Machinability in CNC Machining

The importance of machinability in CNC machining cannot be overstated. Selecting a material with poor machinability can result in increased tool wear, reduced quality of the workpiece, and increased machining costs. In contrast, choosing a material with good machinability can result in more efficient and cost-effective machining, improved surface finish, and reduced tool wear.

Material Selection in CNC Machining

Selecting suitable material for CNC machining involves evaluating factors like mechanical properties, cost, availability, and machinability. Chemical composition, thermal conductivity, and surface finish also factor into the choice of material. Materials that are easy to machine, like aluminum and copper, are often famous in CNC machine shops.

In conclusion, machinability and material selection play essential roles in CNC machining. With a clear understanding of machinability factors and the importance of material selection, CNC machine shops can optimize their machining processes, reduce costs, and improve their competitiveness. Choosing a suitable material with good machinability can result in consistent quality, reduced tool wear, and more efficient machining.

Design for Assembly and Part Consolidation: Streamlining CNC Machining Processes

As the manufacturing industry becomes more competitive, reducing costs and lead time while maintaining quality is crucial. One of the most effective ways to achieve these goals is through implementing Design for Assembly (DFA) and part consolidation in Computer Numerical Control (CNC) machining.

I. Design for Assembly

A. Explanation of Design for Assembly (DFA)

DFA is a design methodology that aims to simplify the assembly process of a product. It involves designing parts to be easily assembled, reducing the number of factors, and minimizing the need for special tools or skills. DFA considers the entire assembly process, from manual assembly to automated assembly.

B. Benefits of DFA for CNC machining

DFA offers many benefits for CNC machining, such as reducing the number of machining operations required, simplifying fixturing, and lowering assembly costs. DFA can significantly reduce cycle and lead time, increasing production capacity.

C. Examples of DFA in CNC machined parts

DFA can be seen in many CNC machined parts, such as motor mounts, brackets, and enclosures. By simplifying the Design, these parts can often be manufactured in a single operation, resulting in cost savings and improved quality.

D. Best practices for DFA in CNC machining

To achieve effective DFA in CNC machining, it is recommended to involve the manufacturing team in the design process, use modular Design, avoid over-engineering, and consider manufacturing capabilities during the design process.

II. Part Consolidation

A. Explanation of part consolidation

Part consolidation involves the combination of multiple parts into a single piece, without sacrificing functionality. By reducing the number of factors, part consolidation offers many benefits, such as decreasing assembly time, reducing inventory, and improving quality.

B. Benefits of part consolidation for CNC machining

Part consolidation offers significant benefits for CNC machining, such as reducing part count, lowering manufacturing costs, and improving part quality. Part consolidation can also enhance the structural integrity of a part or product.

C. Examples of part consolidation in CNC machined parts

Part consolidation is commonly seen in CNC machined parts such as brackets, housings, and cages. Consolidating multiple functions into a single piece simplifies assembly and reduces manufacturing costs.

D. Best practices for part consolidation in CNC machining

To achieve successful part consolidation in CNC machining, it is essential to consider the end-use requirements of the product, use a modular or family approach to Design, evaluate manufacturability options, and analyze cost savings potential.

III. How to Design for Assembly and Part Consolidation in CNC Machining

A. Guidelines for DFA and part consolidation

Guidelines for implementing DFA and part consolidation in CNC machining include understanding product requirements, evaluating design options, choosing efficient machining methods, prioritizing Design for manufacturability, and continuous evaluation and improvement.

B. Tools and software for DFA and part consolidation

Several tools and software, such as SolidWorks, PTC Creo, and CATIA, are available to assist in DFA and part consolidation. These tools offer automated assembly analysis, design optimization, and simulation capabilities.

C. Typical design considerations for CNC machined parts

Design considerations for CNC machined parts include material selection, tolerancing, surface finish, feature complexity, and post-processing requirements.

D. Common mistakes to avoid in DFA and part consolidation

Common errors in DFA and part consolidation include overcomplicating the design, ignoring manufacturability, failing to involve the manufacturing team, and not considering the end-use requirements of the product.

IV. Case Studies: Successful Examples of DFA and Part Consolidation in CNC Machining

A. Case study 1: Aerospace industry application

Aerospace manufacturer Airbus used DFA and part consolidation to design the A350 XWB aircraft. The design reduced the number of parts by 30%, resulting in cost savings and improved assembly efficiency.

B. Case study 2: Medical device application

Medical device manufacturer Medtronic used DFA and part consolidation to reduce the number of components in its new insulin pump. The simplified design resulted in a 10% reduction in manufacturing costs and a 30% reduction in assembly time.

C. Case study 3: Automotive industry application

Automotive component manufacturer Bosch used DFA and part consolidation to design a new brake system. By consolidating multiple parts, Designesign reduced assembly time and costs, improving quality and increasing production capacity.

V. Conclusion

A. Recap of the importance of DFA and part consolidation in CNC machining

DFA and part consolidation offer numerous benefits for CNC machining, such as reducing assembly time, improving quality, and lowering manufacturing costs. By implementing these techniques, manufacturers can improve competitiveness and increase profitability.

B. Recommendations for implementing DFA and part consolidation in CNC machining

To implement DFA and part consolidation effectively, it is essential to involve the manufacturing team in the design process, use available tools and software, and consistently evaluate and improve the