What is a CNC milling machine and what does it do

CNC milling machines are one of the most important advancements in modern manufacturing technology. They allow for precise and efficient cutting, drilling, and shaping of a wide range of materials such as metal, wood, foam and plastic. CNC stands for Computer Numerical Control and these machines are controlled through a computer program. This allows for high accuracy and repeatability when creating parts or components with extremely complex shapes and geometries.

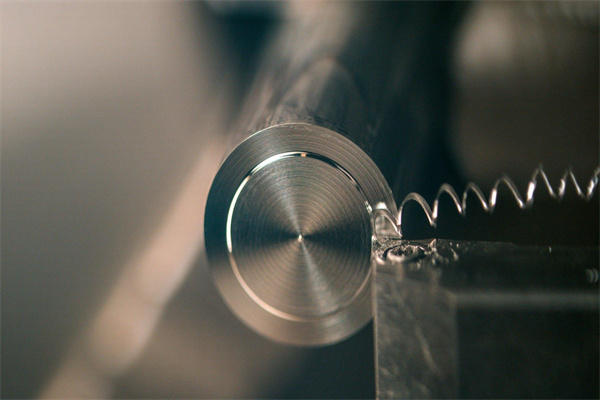

CNC milling machines use a rotary cutting tool to remove material from the workpiece surface by feeding it along the axes of X, Y, and Z which correspond to the vehicle’s left-right (X), front-back (Y), and up-down (Z) directions respectively. The machine is equipped with a spindle that rotates at high speeds with various cutting tools mounted on it. Depending on the type of tool used, it can be used to cut, drill, face off or thread a variety of materials including metals such as steel, aluminum and brass; plastics; wood; composites; foam; wax molds; etc.

Not only does CNC milling create more accurate parts at faster speeds than traditional machining methods such as manual lathes or hand tools, but it also brings about greater design flexibility due to its ability to accurately reproduce complex shapes that would otherwise be difficult or impossible to achieve using conventional techniques. The software used for CNC machining also makes job setup easier than ever before allowing engineers to quickly make changes when needed without having to start from scratch each time something needs altered.

As impressive as they sound however they do not come cheap. The cost of a CNC milling machine depends on its size, capacity and capabilities but you can typically expect to pay anywhere between $5 000 – $50 000 USD depending on what you need. So if you’re looking into getting one for your business, make sure you factor in all the costs associated with purchasing such an expensive piece of equipment like installation fees, software costs, training etc., before settling on one model or another as this will help ensure that you get the best return on your investment over time!

How much do CNC milling machines cost

When it comes to industrial manufacturing, CNC milling machines are a must-have tool. They offer superior precision and accuracy compared to manual machining processes and can help increase productivity and efficiency in the workplace. But how much do CNC milling machines cost?

The cost of a CNC milling machine depends on several factors, including size, speed, and accuracy. Generally, larger machines tend to be more expensive than smaller ones because they’re typically faster and can handle more complex milling tasks. Additionally, machines with higher accuracy may cost more due to their enhanced capabilities.

The type of material you’re milling will also affect the cost of your CNC machine. Harder materials require more powerful machines with advanced features, which can significantly drive the price tag. Furthermore, suppose you plan to use various materials for different projects. In that case, you should look for a machine that offers dual spindle capability or multiple axes for greater flexibility when working with different materials.

Another factor that will influence the price of your CNC milling machine is its features. Many models come with additional options, such as programmable control systems, built-in coolant systems, and integrated air filtration systems, making them ideal for specific applications or industries. If these features are necessary for your project, then you should factor them into the overall cost of the machine as well.

Finally, remember that the initial purchase price is only one part of the total cost of owning a CNC milling machine. You’ll also need to consider ongoing costs such as maintenance, repair parts, and tools required to operate the machine safely. That said, investing in quality machinery from reputable brands can help reduce long-term expenses associated with owning a CNC milling machine while ensuring reliable performance over time.

In summary, there is no one-size-fits-all answer regarding how much a CNC milling machine costs since budgets will vary based on individual needs and preferences and any additional features desired for specific applications or industries. However, by considering all factors related to size, speed, accuracy and features, customers can find reliable machinery at competitive prices that meet their unique requirements without breaking their budget.

Factors that will affect the price of a CNC milling machine

When it comes to CNC milling machines, the cost is often one of the first questions to come up. After all, these machines are essential for many businesses and offer a wide range of benefits, but they can also be an expensive investment. So how much does a CNC milling machine cost? This blog post will discuss the various factors that can affect the price of a CNC milling machine and help you better understand what you’ll be paying for.

Size Matters

The size of the CNC milling machine is one of the factors that can have an effect on its price tag. Generally speaking, larger machines tend to cost more than smaller ones due to their increased complexity and larger parts and tooling requirements. Your project’s size will determine which machine is best suited for your needs, so bear this in mind when budgeting for a machine purchase.

Number Of Axes

Another factor that affects the cost of a CNC milling machine is the number of axes or directions in which it can move. Machines with fewer axes are typically less expensive than those with more axes because they require fewer parts and less time to assemble. However, suppose your project requires multiple axes. In that case, you’ll likely need to invest in an appropriately-sized machine to get the job done—which could mean spending far more than you initially anticipated.

Quality Of Parts

The quality of components used in a CNC milling machine will also affect its price tag significantly. Cheaper components may be good enough for light-duty applications, but if you want consistent performance over time, then investing in higher quality parts may be worth it in the long run—especially since higher quality components usually translate into longer service life and greater precision when machining complex components.

Level Of Automation

The automation level offered by different CNC milling machines can also have an impact on their price tag—although this factor is largely dependent on how much manual intervention your team is willing to commit during operation as well as any additional automation features included with each specific model such as touch probes or ATCs (Automatic Tool Changers). Higher levels of automation generally equate to higher costs, so keep this in mind when deciding which model fits your budget best.

Software Compatibility

Finally, many modern CNC mills are programmable through software interfaces—and this feature can also affect final pricing significantly depending on what type of software support each model offers out-of-the-box (and whether additional software licenses need to be purchased separately). Check what compatibility each model offers before making any purchasing decisions, as this could add significant amounts to your total bill if not accounted for ahead of time!

In conclusion, many factors affect the cost of a CNC milling machine—but understanding them all should make selecting an appropriate model easier and ensure you don’t overspend on features that aren’t necessary for your project requirements. Keep these considerations in mind and take your time weighing up all available options—as doing so can save time and money!

The different types of CNC milling machines available on the market

CNC milling machines have revolutionized the manufacturing industry and made it easier to produce goods with higher accuracy and speed. But with so many different types available on the market, it can be hard to know which one is right for your business. In this blog post, we’ll take a closer look at the different types of CNC milling machines available and how much they cost.

CNC stands for Computer Numerical Control, meaning that a machine can be programmed to carry out complex actions with great precision automatically. The most common type of CNC machine is the CNC milling machine, which is used to create complex shapes and features in various materials such as wood, metal, and plastic.

The cost of a CNC milling machine depends on what type of machine you’re looking for. For example, 3-axis machines are generally less expensive than 5-axis machines because they are less versatile and require less programming knowledge. On the other hand, 5-axis machines provide more flexibility when machining parts from different angles and are typically more expensive than 3-axis machines.

Several other factors affect the cost of a CNC milling machine, such as size (the larger the size, the more expensive it will be) or whether it uses pneumatics or hydraulics (pneumatics typically costs more). Additionally, some models come with built-in safety features such as limit switches or emergency stops which increase their cost but make them safer to use.

Another important factor to consider when buying a CNC milling machine is its accuracy—how precise it can cut shapes or features into the material. Higher accuracy usually comes with higher prices; however, better accuracy may be necessary for some applications like medical device manufacturing, where even minor errors can have serious consequences.

Finally, you should consider additional costs associated with purchasing a CNC milling machine, such as set-up fees or ongoing maintenance costs. These costs can add up quickly, so factor them in when calculating your budget for a new machine.

Recommended Reading:How Much Money Can You Make with a Cnc Machine

In summary, many different types of CNC milling machines are available on today’s market, ranging from small 3-axis models meant for hobbyists to large 5-axis models capable of producing highly intricate parts in high quantities. The exact price you pay for one will depend largely on its size and capabilities but expect prices for mid-range models to start at around USD 50k before any additional costs are factored in.

Which type of CNC milling machine is best for your needs

When it comes to finding the right CNC milling machine for your needs, it’s important to consider various factors. From size and cost to performance and features, it’s essential to consider all aspects before purchasing. Everyone typically wants to know: How much does a CNC milling machine cost? This article will explore the types of CNC milling machines available, their costs, and which one may be best for you.

CNC (Computer Numerical Control) milling machines are automated tools for machining complex parts with extreme accuracy. They come in four basic configurations: vertical axis, horizontal axis, universal, and trunnion. Each of these designs has its own advantages and disadvantages depending on what type of application you need the machine for.

The most popular CNC milling machines are those with a vertical-axis design because they tend to offer higher accuracy and repeatability than other configurations. These machines usually have 3 or 4 axes of motion that control cutting tool movement along the X (Horizontal), Y (Vertical), Z (Depth) axis, as well as rotation around the spindle axis commonly referred to as A (Angular). Vertical Axis mills are typically used for applications such as die sinking, contouring, engraving and surfacing.

Horizontal-axis CNC mills provide an advantage over vertical-axis models by allowing more complex parts and components to be machined. Their greater cutting depth capacity can reach deeper pockets on the workpiece. Horizontal Axis mills can also handle larger workpieces than vertically configured machines since their spindles are mounted horizontally rather than vertically. As with Vertical Axis machines these mills usually have 3 or 4 axes of motion but they can vary between 2-6 depending on specific features required by the application.

Universal CNC Mills are designed similarly to Horizontal Axis models however they feature additional versatility through their ability to move both spindles on separate axes simultaneously in opposite directions which enables them to cut both sides of a part in one cycle significantly reducing down time compared to single-spindle models. This makes them perfect for operations such as face milling or pocket boring where parts need machined quickly and accurately on both sides.

Finally there are Trunnion style CNC Mills which feature a unique design similar to that of an offset printing press that allows them to move both their spindle(s) along two perpendicular rotary shafts often referred to as “trunnions” in addition to moving them along X/Y/Z axis like all other styles mentioned before. This provides very precise control over workpiece positioning which makes them ideal for applications requiring frequent repositioning or small parts adjustment during operation such as drilling patterns in molds or intricate engraving jobs with tight tolerances like jewelry making where each component must be precisely sized and positioned relative one another within fractions of a millimeter (.001 ‘).

Now let’s answer our main question – How much does a CNC Milling Machine Cost? Prices range from around $10k up until several hundred thousand dollars depending on various factors such as size/capacity, type/configuration, brand/model etc… As you can see there is no one answer when it comes purchasing a CNC Milling Machine so make sure you do proper research and select the configuration that best suits your needs taking into account budget limitations if any apply of course!

Where to buy a CNC milling machine

When buying a CNC (Computer Numerical Control) milling machine, the cost is often a major factor. Not only do you need to consider the machine’s price, but also any additional costs such as shipping, taxes, and installation. Before making your purchase, it’s important to understand how much a CNC milling machine will cost.

Let’s start with the CNC milling machine itself. The average base price usually ranges from $20,000 to $50,000, depending on the size and type of machine you get. Some machines are cheaper than others depending on what features they come with. For example, smaller desktop models may cost less than $3,000 for basic tasks like engraving or cutting wood. On the other hand, larger production-grade machines can cost upwards of over $100,000 for more complex operations like machining aluminum and other metals.

The additional costs associated with purchasing a CNC milling machine should also be considered when estimating your total cost. The additional costs include shipping charges if you buy online and any applicable taxes in your area. In addition to this, installation fees may need to be paid if you do not have access to experienced technicians who can install the milling machine correctly without damaging it or incurring any risks of injury or property damage during setup.

If you’re looking for an even lower-cost solution, consider using CNC milling machines from resellers or manufacturers offering refurbished models at discounted prices. Refurbished models can be just as effective in performance but offer significant savings compared to new models since another customer has used them before being repurposed for sale again at a lower price point.

Overall, when considering where to buy your CNC milling machine, it’s important to factor in both upfront and additional costs so that you get the most bang for your buck and end up with an excellent quality product that will last for years to come without having to spend too much money all at once. Making sure that you choose a reputable seller is key when shopping around so take the time to read reviews and get advice from professionals before making your final decision.