When it comes to milling aluminum, there are a few things you need to keep in mind to achieve perfect results. The most important of these is your RPM or revolutions per minute. Get this wrong, and you could damage your workpiece or even injure yourself. This blog post will show you how to calculate the optimal RPM for machining aluminum and some other tips for getting the best results.

The first thing you need to do is determine the material removal rate or MRR. This measures how much material is removed from the workpiece per minute and is expressed in cubic inches per minute (in3/min). To calculate MRR, use the following formula:

MRR = (Feed Rate x Number of Teeth) / (Number of Flutes x Chip Load)

Next, you need to determine the spindle speed. This is measured in revolutions per minute, or RPM. To calculate spindle speed, use the following formula:

Spindle Speed = (MRR x 12) / (Pi x Tool Diameter)

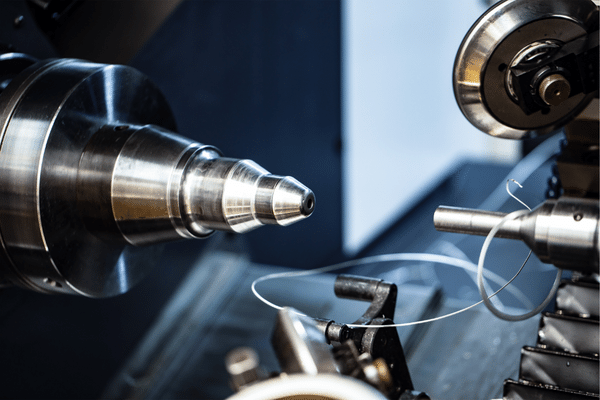

Once you have your spindle speed, it’s time to start machining! But it would help if you kept a few other things in mind to get the best results. First, make sure your tools are sharp and in good condition. Dull tools not only produce poor results, but they can also be dangerous. Second, use coolant when machining aluminum—this will help reduce friction and heat build-up. Finally, take your time and don’t try to hurry the process—rushing can lead to mistakes that could ruin your workpiece.

By following these tips, you can be sure you’ll achieve the perfect results when machining aluminum. And if you have any questions or need help finding the right tools for your project, our team at XYZ Machinery is always happy to assist!

Conclusion:

Machining aluminum requires careful consideration of many factors to achieve perfect results. The most important of these is choosing the right RPM for your project. With a little planning and attention to detail, you can be sure that your next aluminum machining project will be a success!