[lwptoc]

What to look for when buying a CNC machine

Buying a CNC machine is an exciting project that can open the door to new business opportunities. However, it’s essential to understand what you are looking for when purchasing a CNC machine to get the best value for your money. There are several factors to consider, such as size, cost, flexibility, and accuracy.

Size

One of the first considerations when buying a CNC machine is its size. You need to identify how much workspace you need to determine which model and size of the device will best suit your needs. You should opt for a giant machine if you want something more flexible and universal compatibility. On the other hand, if you’re looking for something with more precision and control, go with a smaller engine. To help make this decision easier, most CNC machines come in various sizes with different features and capabilities.

Cost

The money you want to spend on a CNC machine will also be essential in determining which one you buy. Considering the upfront costs of buying a new or used machine and any ongoing maintenance costs is necessary. Look into financing options if needed, or look at refurbished models that may cost less but still have all the features you need. Also, consider any special tooling or software upgrades you may require to use your new machine effectively over time.

Flexibility

Another factor to consider when buying a CNC machine is its flexibility – particularly if you plan on using it for multiple projects. A good quality CNC model should have numerous cutting tools available to handle different materials and shapes efficiently without needing additional parts or accessories added later. The more versatile your CNC model is, the better value it will offer over time – so make sure whatever model you choose has plenty of adaptabilities built into its design.

Accuracy

Finally, its accuracy level is an essential feature to look out for when buying a CNC machine. All models will offer varying degrees of accuracy depending on their build quality and complexity; however, generally speaking, higher-end models will deliver greater precision than lower-end machines due to their increased sophistication and more advanced components used within them. If accuracy is of utmost importance for your projects, then make sure whatever model you purchase has been tested for precision before making any final decisions about purchase plans, together with receiving testimonials from past customers who have experienced success using such machinery previously too.

The different types of CNC machines available

CNC (Computer Numerical Control) machines have become essential to industrial manufacturing in this ever-evolving technological age. CNC machines are automated, computer-controlled tools that create precise details with repeatable results. Many different types of CNC machines are available today, and knowing which is best for your project or business can be daunting. This blog post will help you understand the different types of CNC machines available, so you can decide when buying a CNC machine.

The most common type of CNC machine is the three-axis machining center. This type of CNC machine utilizes three linear axes – X, Y, and Z – and one rotational axis (the A-axis). These four axes can cut complex shapes in three dimensions while maintaining accuracy. These machines come in all sizes, from small desktops to large floor models, and are used in various industries such as aerospace, automotive, medical device production, and more.

Another popular type of CNC machine is the two-axis lathe. This lathe type allows for longer production runs since it does not require changing out tools as frequently as the three-axis machining center. Instead, it utilizes two rotating axes (X and Z) along with stationary cutting tools that can be positioned at any angle along those axes to produce parts with complex shapes from round or oval materials. Two-axis lathes are commonly used for precision turning for shafts, spindles, screws, and more.

Cylindrical grinder machines are also becoming increasingly popular due to their use in grinding intricate shapes into parts made from cylindrical stock materials such as rods or tubes. A cylindrical grinder typically has five axes: X-, Y-, Z-, U-, and V-. The X-Y-Z axis controls the movement of the workpiece. In contrast, the U and V axis controls the rotational speed of a grinding wheel mounted at an angle relative to the workpiece surface, allowing for higher accuracy when grinding complex shapes into various materials, including hard metals like steel or tungsten carbide.

The last type we will discuss here is 5 Axis Machining centers which have become increasingly popular for creating highly accurate parts with features like contours or holes located on multiple sides at once without needing to reposition or reorientate them each time they do a separate operation them. 5 Axis Machining Centers usually have three linear axes – X, Y & Z – along with two additional rotational axes – B & C – enabling full 360° motion around all five axes simultaneously so that even curved surfaces can be accurately machined into a variety of materials ranging from soft plastics to hard metals like stainless steel and titanium alloy depending on what kind you choose to purchase.

When purchasing a CNC machine, there are several things you should consider before making your final decision, such as size requirements based on the material being worked on, accuracy needs to be based on how precise your finished product needs to be, cost factors depending on what level equipment you need, maintenance requirements, design capabilities, safety features, aftermarket support options, etc. Considering all these factors will ensure that you choose a machine that meets your current needs and gives you room for growth should your production requirements increase in future years. Hopefully, this has given you a better understanding of what types of CNC Machines are available today so you can go out there and find one that fits both your production demands and budget.

Factors to consider when choosing a CNC machine

When it comes to buying a CNC machine, there are certain factors that you must consider to ensure you make the right purchase. CNC machines are intricate and complex equipment, so making an informed decision is paramount. Considering all these factors before committing to a purchase can save time and money in the long run. Here are some key things to keep in mind when looking for a CNC machine:

1. Your Budget

– First, you must determine your budget for this purchase. Knowing what you can afford is essential, as this will help narrow your options. Many types of CNC machines are available at various prices, so having a pre-set budget will help you find one that fits your budget constraints.

2. Your Needs

– Second, determine what kind of work you need the machine for. Do you need something capable of cutting stainless steel? Or do you merely require a small 3-axis milling machine capable of basic operations? Once again, understanding what tasks the device needs to accomplish will help narrow your options and make it easier to find one that suits your needs.

3. Space Requirements

– Will the machine fit in the space you have available? Different machines vary in size depending on their capabilities and complexity, so if space is limited, this becomes very important when deciding which model best suits your situation. Additionally, consider whether you may need extra room around the machine, such as additional storage or workspace if needed later on down the line.

4. Voltage Requirements

– What voltage does your existing power supply provide? This is essential information as most CNC machines require three-phase power, and if yours doesn’t match up, it could be an issue when installing it later on down the line. It’s also worth noting that some models come with versions suitable for single-phase power supplies. However, check before purchasing any model just in case it isn’t compatible with what already exists at your facility or building site.

5. Maintenance & Support

– Always ensure good after-sales service from either pliers or manufacturers, incl, including support and troubleshooting advice should anything go wrong with your new purchase. Additionally, check whether spare parts are readily available should any components need replacing sometime soon after installation.

6. Software Compatibility

– Last but certainly not least, consider any software compatibility requirements before purchasing any modern-day CNC machines that now come with their dedicated software but make sure that it works well with other applications used by other members of staff who may be utilizing its functions elsewhere within your business process.

In conclusion, when purchasing a CNC Machine, ensure that all pertinent factors have been considered, including a budget, needs, space requirements, voltage requirements, maintenance & support, and software compatibility. Considering all these items before making any commitment ensures that we get exactly what we want in terms of quality and value for money. Our business processes also face minimal disruption during implementation and integration stages further down the line.

How to find the best price on a CNC machine

Finding the best price on the market can be challenging and daunting for those looking to buy a CNC machine. It is essential to conduct some in-depth research to get the most out of your purchase and ensure you’re getting a good deal. Here are some tips to help you find the best price on a CNC machine:

1. Different Research Brands:

Before you buy, take time to research different brands and compare features. This will help ensure you get a machine that meets your needs and budget. Consider elements like speed, accuracy, reliability, and service before deciding.

2. Shop Around:

While researching brands, look for places with discounts or special offers on their products. Shopping around can help you find the best deals and save money in the long run. Don’t forget to check online retailers too!

3. Consider Used Machines:

Buying used equipment can be a great way to save money while still getting the quality of a new machine. If you have time to search online auctions or classifieds sites, this might be an option worth considering if it falls within your budget.

4. Ask People Who Already Own One:

Reach out to people who already own machines, such as your local manufacturer or business owner, as they may be able to provide insight into where they bought their CNC machines, what kind they have, and how much they paid for them. This information can be invaluable when trying to decide which brand and model is right for you at the right price point

5. Consult With Professionals:

Finally, don’t hesitate to seek expert professional advice when searching for CNC machines at competitive prices. They may have access to special deals or offers that wouldn’t otherwise appear on the market – like bulk orders with heavily discounted rates – so always ask someone with experience if any hidden gems are available before making a purchase decision!

In conclusion, finding the best price on a CNC machine requires research – both online and offline – and asking questions of experts who might know about exclusive deals not available elsewhere. By following these simple steps, anyone should be able to find an affordable but reliable CNC machine without compromising on quality or performance!

Where to buy a CNC machine

Are you looking to invest in a CNC machine for your business or project? It is essential to understand the various types of CNC machines available and how to select the best one for you. With numerous options, deciding which engine suits your needs can be difficult. This blog post will provide insight on how to buy a CNC machine, including information on the different types and features of these machines, all while keeping an eye on cost-effectiveness.

First and foremost, it’s essential to determine what type of CNC machine you need. Many different categories vary significantly in terms of what they can accomplish. The most common types are milling machines which carve out shapes from raw materials like wood or metal; lathes which rotate material against cutting tools; routers which cut away fabric; and 3D printers, which deposit successive layers of plastic or other materials for rapid prototyping. Knowing the purpose of your CNC machine will help narrow down the selection process and ensure that you purchase the appropriate tool.

It’s also important to consider size and power when selecting a CNC machine. This is typically determined by considering the area where it will be located and how large or intricate projects will be created with it. For instance, if you work with larger objects like furniture or sculptures, you may need a giant CNC machine more than when dealing with smaller items like jewelry or electronic components. Some devices come with adjustable speeds, so consider this when purchasing.

In addition to size and power considerations, pay attention to precision when selecting a CNC machine, as different models have varying levels of accuracy when creating detailed pieces. Pay attention to maximum and minimum accuracy since this will affect how closely pieces match up during manufacturing processes like welding or assembling parts in production lines. Additionally, look at any safety features included in the model, such as motion sensors that stop movement if an object enters its path and emergency shut-off buttons located near areas where people might interact with moving parts while working on projects.

Finally, factor cost into your decision-making process when buying a CNC machine, as there are many options available at various price points depending on the features desired and the level of accuracy needed for particular projects. Factors such as software compatibility (Windows vs. Mac OS), control system/interface used (G-code vs. EMC2), and warranty should also be considered since these can impact overall cost over time. Additionally, compare prices between different vendors online before making any purchases, as discounts may be available depending on where you shop for deals!

Investing in a quality CNC machine can bring tremendous value if done correctly – understanding the types available and considering size/power specifications and precision desired can help ensure you make an informed decision about purchasing one without breaking the bank! Remember safety features too – having sensors stop movements whenever something enters its path is essential – but don’t forget about warranties either since these can save money over time should any unexpected issues arise during the operation of your new device!

How to set up and use your new CNC machine

—

If you’ve recently purchased a new CNC machine, you may wonder how to properly set up and use it to its fullest potential. In this blog post, we’ll cover all the basics of setting up and using your machine so that you can take full advantage of its capabilities to get the best results from your projects.

Firstly, it’s essential to read the manual for your CNC machine carefully and ensure it is compatible with any third-party software you might need for programming or controlling the machine. If necessary, consult an expert in the field if there are any questions or details that you don’t understand. Once everything is confirmed as compatible and set up correctly, you can begin assembling your CNC machine by following the instructions provided by the manufacturer. Taking time during assembly is essential, as incorrect assembly could lead to inaccurate cuts or other problems.

Once the machine is assembled and connected to a power source, you need to ensure that all settings on the control panel are adequately calibrated before beginning operation. Parameters such as speed, acceleration, cutting depth, and the feed rate should be adjusted according to specifications provided in the operation manual for optimal performance of your CNC machine. After these settings have been made correctly, check for any signs of wear or damage on moving parts before starting the machine for operation.

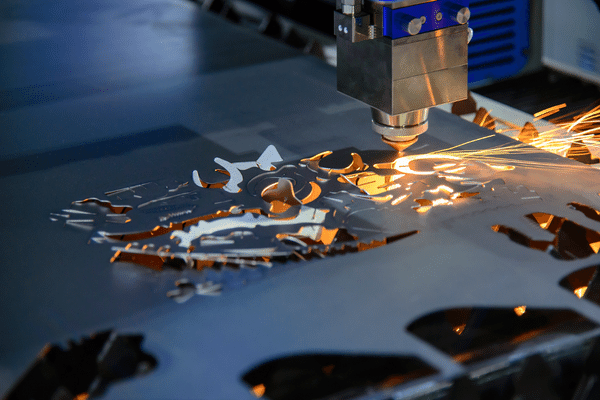

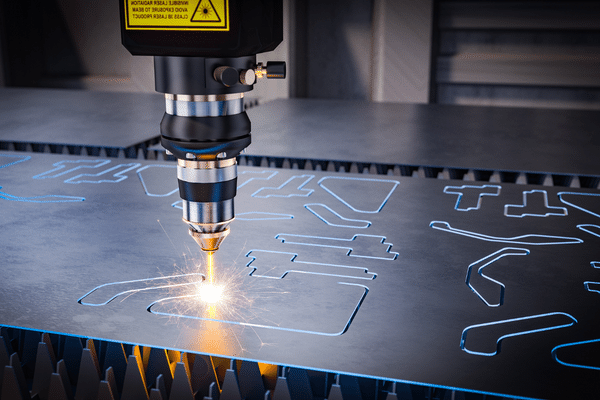

After ensuring everything is in order and functioning correctly, it’s time to start programming your CNC machine using a proprietary software package or a third-party application like CAM software. Simply inputting paths into a CAM program will create g-code instructions, which your CNC machine will use to accurately complete tasks such as cutting metal sheets or other materials. When programming complex shapes with multiple tool paths, always double-check that each course is correct before running them through the CNC machine; even small mistakes can cause significant delays in production line processes or cause damage if they’re not spotted.

Finally, when beginning operations, it’s essential to remember safety, as accidents can occur quickly due to moving parts accelerating at high speeds near on-site workers. Before starting operations, ensure everyone present has been briefed on proper safety protocols, such as wearing protective eyewear while near operating machines and keeping hands clear of sharp edges when cutting materials with a CNC machine. Furthermore, ensure ventilation systems work efficiently because certain materials may be hazardous when exposed over long periods without proper air circulation.

By following these simple steps when setting up and using a CNC Machine, you’ll get optimal performance out of your equipment while keeping everyone safe during operations – ensuring everyone enjoys their work with peace of mind! So if you’ve just bought yourself a new CNC Machine – congratulations! We hope this guide helped explain how easy it is to set up and use one successfully – happy cutting!