CNC Machining: Still a Relevant Trade for the Modern Era

For years, CNC machining has been an important part of manufacturing. But with the introduction of new technologies, there’s some concern that this once-essential trade may be on its way out. Is CNC machining still a relevant trade? Let’s look at some of the reasons why it’s still an important part of modern manufacturing.

CNC Machining and Automation

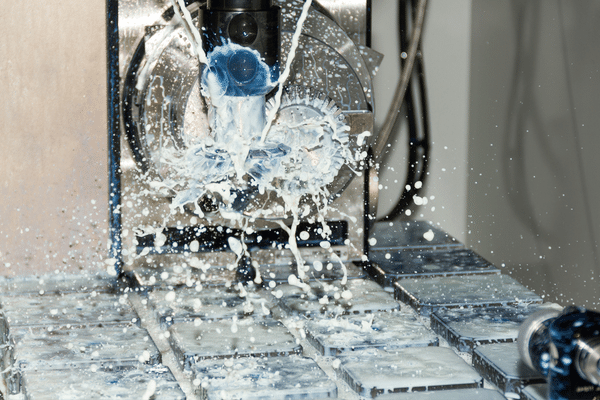

One of the main advantages of CNC machining is that it allows for the automation of production processes. Automation is becoming increasingly important in modern manufacturing, allowing companies to increase efficiency and reduce costs. By automating certain processes with CNC machines, companies can save time and money while increasing their productivity. This makes CNC machining an attractive option for many manufacturers looking to streamline their production process.

CNC Machining and Customization

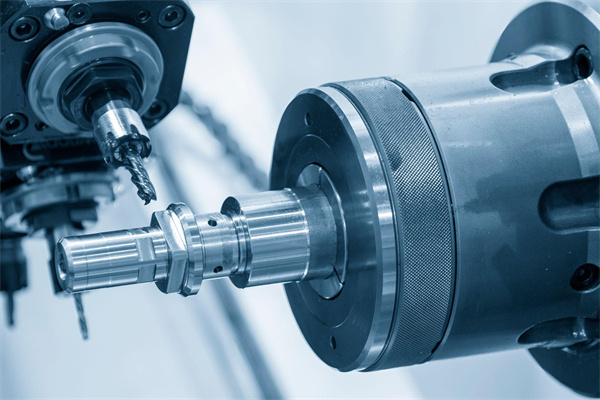

Another advantage of CNC machining is that it allows for customization in production processes. With today’s customer demands for unique, customized products, being able to quickly and easily customize products is critical for success. With the help of CNC machines, manufacturers can quickly and accurately create custom products with minimal effort. This means that companies can meet their customers’ needs in a timely manner without sacrificing quality or accuracy.

CNC Machining and Quality Control

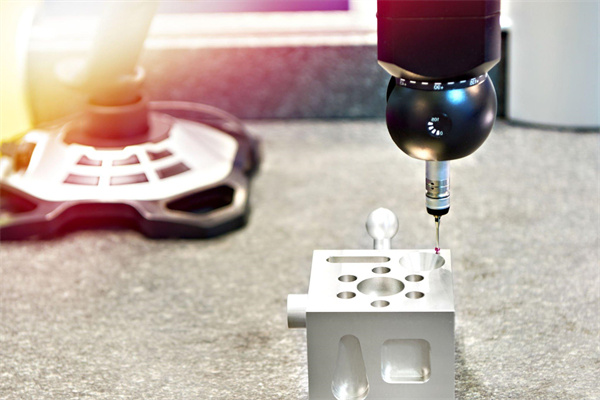

Finally, one of the most important benefits of using CNC machines is that they allow manufacturers to ensure high levels of quality control in their production process. By using automated tools such as CAD/CAM software, manufacturers can easily check each step in the manufacturing process to ensure that everything meets quality standards before moving on to the next stage. This ensures that all products made by a company are consistent and up to par with industry standards.

In conclusion, it’s clear that CNC machining is still very much relevant in today’s world. From automation to customization and quality control, this once-essential skill set is now more important than ever—especially when considering customer demands for unique products with high levels of accuracy and consistency. So if you are thinking about buying a CNC machine or hiring someone skilled in this trade, rest assured that you will make a sound investment!

Understanding the Benefits of CNC Machining for Wholesalers

CNC (Computer Numerical Control) machining is an automated process that uses computer-programmed commands to control machine tools such as lathes, mills, routers, and grinders. This significantly reduces turnaround time and cost compared to manual machining operations. In this article, we’ll discuss the benefits of CNC machining for wholesalers.

Increased Efficiency

CNC machines can run 24/7 with minimal human intervention. This means that you can produce more parts in less time, resulting in higher productivity and increased efficiency. In addition, because CNC machines are programmed with a specific set of instructions and parameters, they are able to produce complex parts with accuracy and precision. This reduces the amount of scrap material produced and helps ensure that each part meets quality standards.

Cost Savings

The use of CNC machines also helps reduce labor costs by eliminating the need for manual labor in many cases. Because CNC machines are programmed to run autonomously, they require fewer people to operate them than manual machinery would require – thus reducing overall labor costs associated with production. Additionally, since the machines are programmed to run autonomously, they don’t need regular maintenance or repairs like manual machinery would require – resulting in additional cost savings over time.

Improved Quality Control

Using CNC machines can also help improve quality control by ensuring that each part meets predetermined specifications and tolerances. Because these machines are programmed with precise instructions and parameters, they are able to consistently produce parts that meet quality standards without needing any manual adjustments or corrections along the way – resulting in fewer defects and improved quality control overall. In conclusion, CNC machining offers numerous benefits for wholesalers looking to increase efficiency and reduce costs while improving quality control standards. By using automated technology such as CNC machines, wholesalers can gain access to superior manufacturing capabilities while reducing their reliance on manual labour – ultimately leading to greater profits in the long run. With its ever-increasing popularity among manufacturers worldwide, it’s clear that investing in a good quality CNC machine is an important decision for any business looking to stay ahead of the competition.

The Growing Demand for CNC Machining Knowledge

With the rise in demand for custom-made products, many businesses are turning to CNC machines to help meet their needs. CNC machining uses computer numerical control (CNC) machine tools to cut and shape materials into precise parts according to the customer’s specifications. It can be intimidating and overwhelming for those who have never worked with a CNC machine before. Understanding the basics of CNC machining is important before investing in a machine.

What Is CNC Machining?

CNC stands for Computer Numerical Control, and it is a type of automated manufacturing that uses computers to control and automate the entire manufacturing process from start to finish. This includes setting up the machines, programming them, running tests on them, and ensuring they work correctly.

The Benefits Of Using A CNC Machine

Most businesses have found that using a CNC machine has been beneficial because it reduces labor costs and increases accuracy compared to manual processes. Additionally, CNC machines are able to produce high-quality products that are consistent in size and shape every time. This consistency helps customers feel more confident about buying from your business, knowing that each product will be made exactly as expected. Furthermore, because all operations can be performed automatically by the machine, production times are greatly reduced, leading to faster turnaround times for customer orders and higher customer satisfaction levels overall.

Knowledge Needed To Operate A CNC Machine

Operating a CNC machine requires knowledge of both programming languages and machining processes, such as cutting tools selection, tool path optimization, and speed optimization techniques. Before investing in a new or used machine, it is important to ensure you have personnel on staff knowledgeable enough to operate it properly or hire additional personnel trained in these areas if needed. Additionally, having employees attend regular training seminars or courses related to operating a CNC machine can ensure they stay up-to-date on best practices when using the equipment so they can continue producing high quality results every time without fail. This knowledge also helps protect your investment since knowledgeable operators are less likely to make mistakes when running these machines, which could lead to costly repairs or replacements if left unchecked over time.

As demand for custom products continues to increase, so does the need for businesses that use advanced technology such as CNC machines for production purposes. It is important for potential buyers of these machines to understand what knowledge is necessary to operate them safely and effectively so they can get maximum return from their investment while providing high quality results each time without fail. Investing in proper staff training and attending industry seminars or courses can help ensure your employees remain up-to-date on best practices when operating these advanced pieces of machinery so you can continue meeting customer demands with confidence now and into the future!

Harnessing the Power of CNC Machines to Increase Profitability

CNC (Computer Numerical Control) machines are incredibly powerful tools that can revolutionize the way you manufacture products. They are capable of producing parts quickly and precisely, allowing businesses to increase productivity and reduce costs. This blog post will explore how to take advantage of CNC machines and make your business profitable.

Choosing the Right Machine for Your Needs

The first step in taking advantage of CNC machines is selecting the right machine. You need to find a machine that fits your budget, as well as one that meets your exact needs. Factors such as size, power, speed, accuracy, and complexity should all be taken into consideration when shopping for a CNC machine.

Maximizing Efficiency with Automation

Once you’ve chosen a CNC machine, maximizing its efficiency by automating processes is the next step. Automation allows you to produce parts faster and more efficiently than ever before. This can help reduce costs while simultaneously increasing productivity. Automation also helps free up time for other tasks, allowing you to focus on other aspects of your business.

Using CAD/CAM Software for Designing Parts

CAD/CAM software is another important tool for taking advantage of CNC machines. This software allows you to design parts your machine can produce with minimal effort easily. It also allows for easy editing and modification of existing designs to create custom parts quickly and accurately.

CNC machines are powerful tools that offer businesses unprecedented control over their production processes. By choosing the right model and harnessing the power of automation and CAD/CAM software, businesses can maximize both efficiency and profitability while reducing costs associated with manufacturing parts or products in-house. With these strategies in mind, any business owner should feel empowered to take full advantage of their new CNC machine!

CNC Machining: An Essential Tool for the Industrial World

The industrial world has come a long way since the days of manual labor and machinery. Computer Numerically Controlled (CNC) machining is essential to many industries, from manufacturing to aerospace. CNC machining is a process that uses computer-controlled tools to create components with precision and accuracy, making it an indispensable tool for industry professionals. Let’s take a closer look at what makes CNC machining so important and why buyers should consider investing in this technology.

The Benefits of CNC Machining

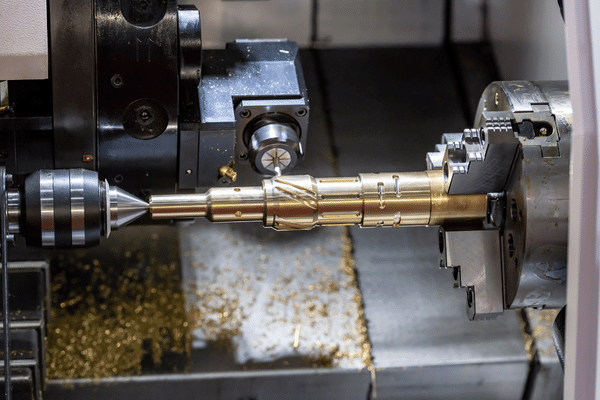

CNC machining has revolutionized the industrial sector, allowing manufacturers to produce more accurate and efficient components. By leveraging computer-controlled cutting tools and machines, CNC machinists are able to create parts with exacting precision that would have been impossible to achieve through traditional methods. This level of precision also allows for shorter production times, resulting in lower costs for manufacturers and buyers alike. In addition, CNC machines are highly versatile, allowing them to be used for various tasks such as drilling, tapping, milling, turning, and more.

Another major benefit of CNC machining is its ability to produce complex shapes easily. Thanks to its computer-controlled tools and machines, CNC machinists can easily create intricate designs that would otherwise require multiple separate processes or extremely skilled manual labor. This versatility allows manufacturers to quickly produce complex parts without investing in additional equipment or personnel. As a result, buyers can expect shorter lead times when ordering components from CNC facilities.

Furthermore, CNC machines rely on computers rather than human labor power, so they can operate nonstop without requiring breaks or rest periods. This means that companies can increase their productivity while reducing their overall costs associated with labor expenses—making it easier for them to profit on their projects. In addition, because these machines require minimal maintenance, they pose no risk of breakdowns or repair costs. This adds value for companies looking for reliable tools at affordable prices.

In conclusion, CNC machining is an invaluable tool for industrial professionals due to its high accuracy and efficiency levels and ability to produce complex shapes quickly and easily. By utilizing this technology, businesses can reduce both production time and labor costs while increasing their overall productivity levels—making it essential for any company looking to stay competitive in today’s market. For those considering buying a machine such as this one, the benefits far outweigh any initial investment cost, making it well worth consideration by any organization looking to gain an edge over the competition in terms of quality products at low prices!