When machining Teflon, speed and feed rates will be determined by its dimensional and mechanical properties. It is a thermoplastic and fluoropolymer, which means it is chemically resistant and non-stick. However, machining Teflon can be more difficult than other materials because it deforms under high pressure and heat. It is best to avoid using this material for unbalanced components or on pieces that have a high tolerance.

PTFE is a thermoplastic

The surface quality of a polymer part is critical to the quality of the finished part. One of the primary factors that affect the surface integrity of a polymer part is cutting force. Several studies have examined the influence of cutting force on the surface quality of PTFE. One such study, conducted by Xiao and Zhang, found that the curl directions of chips are correlated with the surface integrity of the workpiece. Similarly, Okuda and Nunobiki studied the influence of cutting force on chip formation and surface integrity of PTFE during diamond cutting.

The material’s milling temperature increased as the spindle speed increased, while the feed rate decreased. It reached its highest temperature of 135.7 degC when machined at five mm/s. However, the material’s surface quality was poor due to high viscoelasticity.

Thermoplastic materials are popular for use in optical, biological, and aerospace engineering. Many of these materials have excellent mechanical properties and are easy to manufacture in mass quantities. However, these materials can also be difficult to cut and assemble. In addition, they have a low modulus of elasticity and a high coefficient of thermal expansion. Cutting of thermoplastics requires special attention to ensure the integrity of the finished surface.

In general, Teflon is easier to machine than metals, but it requires special attention to achieve a high level of surface quality. The best way to make a Teflon part is to design the part around its properties, as it is not an easily substitute for other thermoplastic materials. The tolerance of Teflon is approximately 0.13 mm, and tighter tolerances can be obtained by stress-relieving it.

It is a fluoropolymer

Teflon is a thermoplastic material that is resistant to heat and chemicals, making it a popular material for machining. It is also a versatile material, used in a variety of applications, including heat exchangers. Its desirable properties also make it suitable for coatings. There are several methods to fabricate Teflon parts, including CNC machining.

Teflon is a fluoride-based, thermoplastic polymer. It is available in a variety of colors and is highly resistant to chemicals and high temperatures. It is also a great insulator and is commonly used for low-friction applications. Its low-friction surface texture makes it perfect for a variety of applications, from kitchen cookware to high-tech medical instruments and seals.

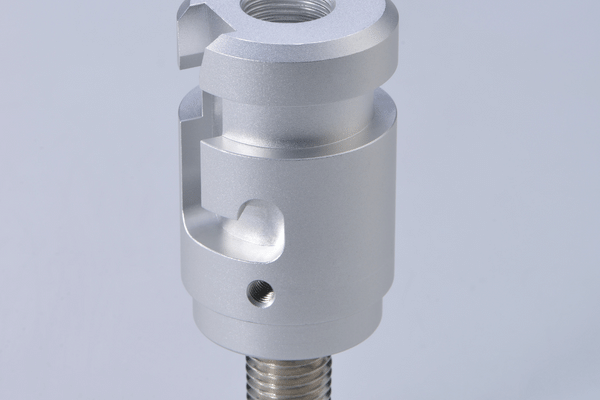

Teflon has excellent chemical and mechanical resistance and is ideal for machining fasteners and bearings. The material is also remarkably soft, so burrs won’t rub off or otherwise deflect. Additionally, it doesn’t wear out tools like metal or plastics. It is also suitable for load-bearing support seats.

Another important characteristic of TEFLON PTFE resins is that they exhibit low thermal conductivity. Heat generated at the cutting edge of a plastic part will not quickly dissipate, which can lead to undesirable marks. Therefore, it is important to consider these effects when planning your machining procedures. Coolants are also highly recommended, especially for machining at high speeds.

It is non-stick

Teflon is a highly slippery plastic that has low coefficient of friction, making it ideal for parts that need to slide smoothly. It is also resistant to most chemicals and high temperatures. The material is also easily cleaned. Many industries rely on Teflon in parts, from the food and beverage industry to high-tech medical instruments. It is even used to coat plumbing joints.

However, plastic parts are not ideal for processing with PTFE due to its tendency to deform under extreme pressures. As a result, machining with Teflon is not appropriate for unbalanced components, such as gears or gearboxes. Furthermore, machining with Teflon has to be done with extreme care, because of its high thermal expansion, which means that it can become damaged even if the part is perfectly balanced.

To prevent Teflon from being damaged, you need to keep your tools sharp and the feed rate slow. In addition, use a coolant that will help the material remain cool. Then, use the proper tooling for the job. These tools will help prevent Teflon from sticking and tearing.

Teflon is made of PTFE, which is a type of thermoplastic. This means that it will melt under heat, while thermosets will remain solid once formed. Knowing these differences is vital to CNC machining. The fluoropolymer used in Teflon is a semi-crystalline thermoplastic. It has outstanding resistance to chemicals and is highly resistant to heat and friction.

It is chemically resistant

Teflon is a versatile material used in a variety of applications. Its machining capabilities require a degree of expertise in the material and skills in operating a CNC machine. Unlike metals, however, the material does have certain limitations and may deform under extreme pressures. Other limitations include a high coefficient of expansion and poor tolerances. As a result, machining Teflon requires non-aromatic water-soluble coolants.

To avoid chip build-up and tool wear, Teflon should not be machined at high speeds. The tool should have a minimum of 20 degrees of clearance and high feed rates should be avoided. The maximum radius for a Teflon cutter is dependent on the stiffness of the part. Generally, a small radius is better than a high feed rate, but high feed rates can result in a bod finish.

Chemical resistance is another property of Teflon. It can be used to protect a wide range of surfaces from corrosion. For example, it can be used to protect electronics from electrical current and heat. It also prevents rust and other contaminants from getting into a machine.

Amorphous perfluoropolymers have several advantages over crystalline counterparts. Amorphous perfluoropolymers exhibit better mechanical properties and excellent thermal resistance. They also possess excellent optical clarity. In addition, they exhibit the lowest dielectric constant of any polymer known to mankind.

It has a low coefficient of friction

Teflon is a soft engineering plastic with a low coefficient of friction that is widely used in machine tools. It is known to be the slickest solid in the world, and its properties make it an excellent choice for machining. PTFE machined parts are used in a variety of industries, including semiconductors, mechanical equipment, and seals.

Generally, the coefficient of friction is influenced by the amount of relative motion between the tool and the workpiece. It is higher in the sticking friction zone than in the sliding friction zone. This is due to the low normal compressive stress in this zone, and a lack of relative motion between the tool and workpiece. A high coefficient of friction promotes a large number of irregularities on the surface of the part. Additionally, it can result in material pullout and peeling.

During the turning process, the friction coefficient is extremely difficult to measure due to the high machining speed and the removal of chip. As a result, some authors have estimated it by theoretical analysis. However, this indirect measurement method introduces error into the data. A more accurate way to determine COF for machining applications is by conducting a tribological analysis of tool-workpiece contact.

Teflon’s low coefficient of friction means that machining it with high-speed tools is not difficult. The shear force of the tool is also related to the material’s hardness, and the angle of the cutting tool. The latter has the advantage of reducing the amount of material that reaches the cutting tool, which can increase tool life.

It can be machined with carbide cutters

Carbide and HSS are two types of hard materials for cutting tools. Carbide has higher hardness and bend-strength toughness than HSS. They are suitable for machining plastics. HSS is also suitable for machining aluminum, wrought alloys, copper, nickel alloys, and some cast alloys. However, bronze is difficult to machine.

Carbide cutters come with a variety of coatings to increase their hardness and performance. These cutters are the most common type of tool used in modern machining. They offer good hardness and workability in most materials and are much less expensive than diamond.

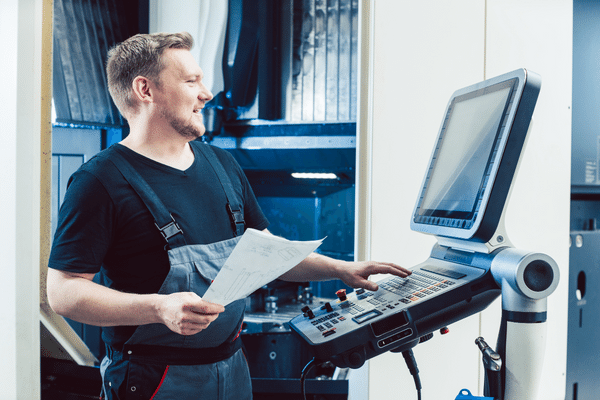

CNC machining can be a great option for machining Teflon. It is a highly accurate process with close tolerances, and can save time and money. However, a lot of care should be taken when machining this material. It is crucial to use sharp tools and a slow feed rate. Additionally, it is recommended to use coolant while machining Teflon.

Teflon is not a single material, but a composite of AlN and TiN. The compound consists of TiN and AlN bonds in a crystalline matrix. This material is much harder than carbide and chrome. The compound is also more resistant to chipping.