While the market for casting parts is still growing, there are some manufacturing companies that stand out among the rest. These companies manufacture a variety of different parts, including mold rubber, wire, iron powder, and more. Check out the Top 10 Casting Parts Manufacturers in 2022.

What are Casting Parts?

If you’re new to casting parts, there are a few things you need to know before getting started. Casting parts is a process where objects are made from a mold or die. These molds can be used for products such as toys, car parts, and other large objects. Casting is a great way to get your products quickly and at a lower cost than traditional manufacturing methods.

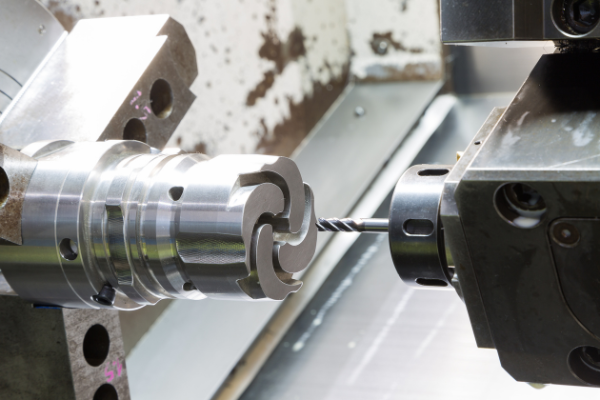

Casting parts are parts that are produced through a process of computer-controlled machining. The benefits of this manufacturing process are that the parts can be made with precision and with high levels of accuracy. Additionally, the parts can be produced in a variety of different shapes and sizes, which makes them ideal for a variety of applications.

What are the Advantages of Casting Parts?

There are many advantages to casting parts. Casting parts can be made quickly and cheaply, which makes them a popular choice for manufacturers who need to produce large quantities of products quickly. Additionally, casting parts can be customized to meet specific requirements, which can make them a more effective solution than using traditional manufacturing methods. Finally, casting parts can be easily replaced if they fail, which reduces the risk of downtime and loss of revenue.

The Disadvantages of Casting Parts?

Casting parts is a common way to create customized objects or products. The advantages of using casting parts are that they are easily customized and mass-produced. However, there are several disadvantages to casting parts. First, casting parts often have low accuracy, which can cause problems when the part is used in a product. Second, casting parts can be brittle and prone to breaking, which can make them difficult to use. Finally, casting parts often require special tools and techniques, which can add to the cost of manufacturing a product.

Especially recommended Top Casting Parts Manufacturers: ETCN

We offer machining services covering different fields, from simple stamping to complicate CNC machining and manufacturing. We struggle with what to call ourselves since we are not a traditional machine shop, seller, or metal parts service bureau. Regardless, once you work with ETCN, you will call us a trusted and professional partner.

website:https://machingchina.com/

2. gabrian

Gabrian International (H.K.) Ltd. was founded in 1995

If you have a complex part design, they can turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality, they work with ISO 9001- 2015 certified manufacturing partners in India to guide you through every step of the process. From tool design to finishing and then on to shipment, they ensure that every project is completed to a high standard and that your parts are shipped on time.

website:https://www.gabrian.com/die-casting/

3.ryobi

Since its establishment in 1943, Ryobi has accumulated innovative technologies by making primarily a wide range of components for the automobile industry. Ryobi has leveraged these technologies and drawn on its experience to diversify into making builders’ hardware and printing equipment.

Ryobi is one of the top manufacturers of die-cast parts for cars. Thanks to its extensive range, it has had great success supplying cylinder blocks, transmissions cases, subframes, and other chassis parts to car companies around the world.

website:https://www.ryobi-group.co.jp/

4.kyowa-casting

They started casting aluminum alloys 75 years ago, in January 1943.

Initially, they used a scrap of hard aluminum, an aircraft material produced by Mitsubishi Heavy Industries Mizushima Aircraft Manufacturing Co. to cast household appliances such as pots and kettles.

With the start of automobile production in Japan after the war, they began producing aluminum alloy castings for automobiles in January 1946, and since then have mainly produced aluminum alloy castings for automobiles and agricultural machinery.

They have accumulated a lot of aluminum alloy casting technology from their various experiences and research for more than 75 years.

website:https://www.kyowa-casting.co.jp/

5.A&B Die Casting

For over 70 years, A&B Die Casting has been supplying lower volumes to manufacturers around the world. We provide solutions for your production needs, from the formative stages of engineering and prototyping to machining, finishing, and assembly, all to your specifications.

They offer a wide range of related services, including engineering, designing, machining, finishing, and assembly. They specialize in low to medium-volume solutions with competitive prices.

website:https://www.abdiecasting.com/

6.Carteret Die Casting Corporation

Founded in 1960 by Joseph A. Dapsis, Carteret has established a reputation as a leader in the production of precision zinc components.

From a two-man, two-machine shop to a 21,000 square-foot state-of-the-art manufacturing facility, Carteret Die Casting is proud of its machines ranging up to 250 tons.

With over 20 modern casting machines and up to 20 types of casting processes, Carteret Die Casting is proud of its impressive technology and skillset.

website:https://www.carteretdiecasting.com/

7.Aluminum Die Casting Company, Inc.

Since 1950, they have specialized in aluminum die casting and zinc die casting. They offer turnkey operations from design or blueprint to the assembly of our products.

ADC specializes in short or medium-run requirements (50 to 100,000) and can handle your expedited requirements for tooling and production complete to your solid model and specifications including Billet CNC Machining, Mechanical Assembly, Plating, Powder-coating, and Painting.

website:https://www.adc3900.com/

8.Impro Industries USA, Inc.

Impro Industries is globally recognized as a leading provider of sand castings. They have over 20 years of experience in creating high-end, geometrically complex sand castings from high-grade materials.

They offer both machine and manual molding operations for resin sand casting, and we produce our parts in low or high volumes.

website:https://www.improprecision.com/

9.Modern Aluminum Castings Co., Inc.

Since 1919, Modern Aluminum Castings Co., Inc. has built a tradition of quality engineering excellence to assure your complete satisfaction no matter what type of casting you to need.

Modern Aluminum Castings offers customers full-service die castings and related capabilities from design to delivery. We work with a variety of metal options and make them available for all types of businesses.

website:https://modernaluminum.com/

10.Fast-Rite International, Inc.

Fast-Rite was founded in 1992 by George I.

Fast-Rite is committed to providing the highest quality fasteners, stamping, castings, assemblies, and components. Our product lines also include plastic injected molded components, abrasives, anchors, tools, and tool accessories, to name a few.

If you are looking for high-quality die castings, Fast-Rite International has the capabilities. We have experience working with materials such as carbon steel, alloy steel, stainless steel, and heat-resistant steel. Our expert engineers will work with you from start to finish, and our quality control team enforces all ISO:9001 protocols during every phase of the process.

website:https://www.fast-rite.com/

Casting parts manufacturers are always in need of new talent to fill their roles. In this article, we highlighted 10 casting parts manufacturers that you should keep an eye out for in 2022. These companies are known for their quality work and will be looking to hire new employees in order to keep up with the demand for their products. Check out our list and see which company might be a good fit for you!