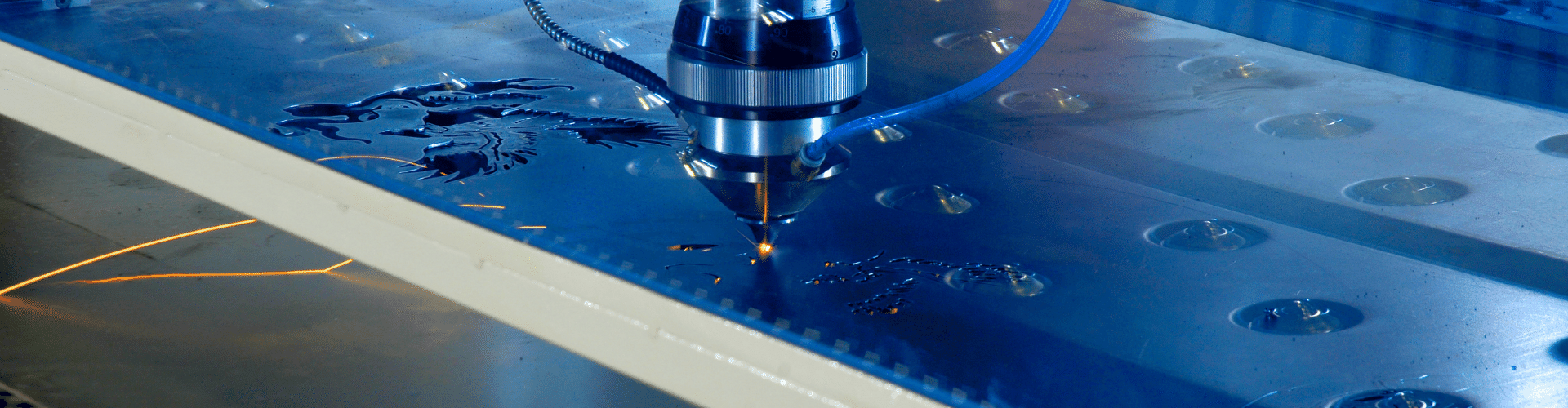

The computer-aided design and manufacturing or Computer-Aided Design and Computer-Aided Manufacturing or CAD/CAM are extremely helpful tools in receiving the required precision for cutting sheet material with high accuracy. The available CNC software has made it easier for users to develop their prototypes without having any hardware tools in the present times.

What Is CAD/CAM Software?

CAD/CAM software is used to create and modify digital models of objects. These digital models can be used to create a physical object by computer-controlled machines. They may be used for other purposes, such as designing and manufacturing products. CAD/CAM software combines the letter C for computer with CAD for Computer Aided Design and CAM for Computer Aided Manufacturing.

CAD/CAM software works by allowing users to create 3D models that can then be modified with ease. This allows designers to create new products without starting from scratch each time they have an idea. It also allows them to change their minds about a design without having to go back through many steps to make those changes.

There are many different types of CAD/CAM software available today, including free programs that are available online as well as paid versions sold by major software companies like Autodesk and SolidWorks. These programs allow users to manipulate their designs in multiple ways, including adding more detail or changing the shape of an object completely if desired.

The first CAD/CAM programs were created in the late 1960s at Stanford University under Dr. Norman McClean’s leadership; these programs were called PROLITH (PROCESS FOR REAL-TIME LITHOGRAPHY) and PROFIT. The two programs were used together to create a digital version of an object that could be sent to a machine called the CAM (Computer Aided Manufacturing) system, which would then carve the object out of stone based on the data provided by PROLITH/PROFIT. This groundbreaking technology allowed designers to make changes to their work without having to re-create each piece; instead, they could adjust their designs digitally and send them back through the CAM system for carving.

8 Best CAD/CAM Software for CNC Applications

CAD/CAM software is a program to create three-dimensional models from 2D drawings. CAD stands for Computer-Aided Design, while CAM means Computer-Aided Manufacturing.

There are many CAD/CAM software available in the market. Some of them are free, while some are paid. So, before buying any CAD/CAM software, you must check its features and compare them with other available options in the market.

If you want to choose for yourself, then check out these 8 best CAD/CAM software for CNC applications:

Fusion 360

Fusion 360 is cloud-based CAD software that works on Windows, Mac, and Linux. It offers an easy-to-use interface and can be downloaded for free.

The software has been designed to help you advance your designs with features like modeling and simulation. With a wide range of tools available in the software, it is easy to find the right one for your project.

It also has a library that allows you to find the exact file or component you need for your project. This will make it easier for you to get started on any design project regardless of its complexity level.

The software has been developed by Autodesk, a company known for producing some of the most powerful design tools professionals use worldwide. It is, therefore, no surprise that Fusion 360 has earned itself a reputation as one of the most reliable and popular choices among designers today.

Key Features:

Flexible work environment – You can work on multiple projects in one workspace without worrying about losing track of their progress due to overlapping files or folders.

Advanced modeling capabilities – The software provides advanced model editing tools that make it easy for even beginners to create complex models quickly.

Versatile file formats – You can save files in various formats such as DWG, DXF, and STL to make it easier for you to share them with other CAD users.

High-quality renderings – The software offers a wide range of high-quality rendering options that make it easy for you to create photorealistic images of your 3D models.

Free CAD

FreeCAD is a free, opensource parametric 3D modeler.

FreeCAD is a parametric 3D CAD modeler. Parametric modeling allows you to easily modify your design by going back into your model history and changing its parameters. FreeCAD is aimed directly at mechanical engineering and product design but also fits in a wider range of uses around engineering, such as architecture or other engineering specialties.

FreeCAD is open source (LGPL license) and completely modular, allowing for advanced extension and customization.

SOLIDWORKS

SOLIDWORKS is a 3D CAD tool that is designed for engineers and designers. It is one of the most popular CAD packages today because it is easy to learn yet powerful enough for complex designs.

SOLIDWORKS has two design modules: SOLIDWORKS 3D CAD and SOLIDWORKS Composer. The 3D CAD module is used for creating mechanical parts and assemblies, while Composer allows you to create 2D drawings from those parts.

The software also has an integrated CAM interface that allows you to generate toolpaths for milling or to turn your parts on your CNC machine directly from within the CAD environment without having to export files or use additional CAM software like Mastercam or Vectric.

EnRoute

EnRoute is a CAD/CAM software package for CNC applications. It provides all the features and functions necessary for machining 2D and 3D parts on a CNC machine. EnRoute uses the same interface as its predecessor, EnRoute 2, with enhancements that make it an even more powerful tool.

EnRoute makes it easy to create complex projects with multiple parts, multiple operations, and multiple machines. Its support for nesting allows you to move parts nested within other parts, simplifying your project layout. It also lets you create custom libraries of stock materials, tooling, and fixtures that can be reused in other projects.

EnRoute’s powerful toolpaths make it possible to machine very complex shapes with just a few clicks of the mouse. The software automatically calculates all necessary parameters, such as feed rates and speeds, so you don’t have to worry about those details when creating your part. It also features advanced control over milling strategies, such as toolpath optimization for faster machining or better surface finish quality.

Carbide Create

Carbide Create is a CAD/CAM software used for CNC machining. It can be used for 2D and 3D drawings and has a built-in CAM system. The software is simple to use and has many features that make it easy to start machining.

Carbide Create has three main modules: Drafting, Modeling, and CAM. Each module contains different tools that make it easier to use Carbide Create for CNC applications.

Drafting Module-The Drafting Module allows you to create 2D drawings from scratch or an existing CAD file. You can export your drawing as an SVG or DXF file so that you can send it off for manufacturing or take advantage of another feature of the Drafting Module called “Trace,” which allows you to trace over any image file or scan and convert it into a vector drawing that can be edited in Carbide Create.

Model Module-The Model Module gives you access to all of the tools needed to model objects in 3D space without having to worry about whether they will fit together properly when they are manufactured on a CNC machine or not because Carbide Create takes care of all this for you! This makes modeling with Carbide Create incredibly simple and easy, especially for beginners who want to get their feet wet with 3D modeling but don’t have any prior experience! It also means that you can use Carbide Create as a standalone modeling program if you don’t need all of the other features in the Drafting Module.

The main drawback of the Carbide Create program is that it has a fairly limited range of tools. If you want to do more advanced modeling, such as adding very fine details to your objects or creating complex shapes with curves and contours, you may need another program like Fusion 360 or OnShape.

Exocad

Exocad is the most popular CAD software for CNC applications in the world. It is compatible with all major operating systems (Windows, Linux, Mac OSX) and supports 3D solid modeling, 2D drafting and drawing, sheet metal forming simulation, and cutting process simulation.

Exocad is a full-featured CAD/CAM software package for creating 2D and 3D designs of molds and dies from any type of product. It also allows users to generate NC programs for CNC machine tools that can be used with Exocad’s integrated NC engine to produce physical parts based on the designs in the software.

The program’s ability to export files in a variety of formats, including IGES, STL, STEP, SolidWorks, and Parasolid, ensures compatibility with other popular CAD/CAM packages such as AutoCAD, SolidWorks, Catia or Pro/ENGINEER.

Estlcam

Estlcam is a 3D/2D CAD system that has been developed for the manufacturing industry. It is used by companies in various industries, including aerospace, automotive, marine, and general engineering.

Estlcam offers a wide range of features for CNC machining, including toolpath generation, post-processing, and simulation. The software also supports other manufacturing processes, such as turning and milling.

The software uses a graphical user interface (GUI) to support the easy creation of parts and assemblies. Users can create functional drawings directly from their 3D models with no need to translate them into 2D drawings first.

The software supports direct model manipulation, allowing users to rotate or zoom into any part of their design without having to move between different views. It also includes tools for editing parts such as fillet radius and chamfer length. This allows users to modify designs without having to switch between programs or toolsets.

In addition to its 3D modeling capabilities, Estlcam includes tools for creating 2D drawings from existing models or from scratch using templates provided by the manufacturer of your machine tool.

The software includes an integrated CAM engine that automatically generates toolpaths based on user input parameters such as material type and depth of cut. The program also includes a postprocessor that allows users to import data from their CAM system and then generate G-code for cutting the part.

Inkscape

Inkscape is a vector graphics editor with capabilities similar to Illustrator, CorelDraw, or Xara X using the W3C standard Scalable Vector Graphics (SVG) file format. Inkscape’s primary vector graphics format is SVG, which can be edited with Inkscape’s GUI or from a command line interface (CLI).

Inkscape’s primary goal is to create a powerful and convenient drawing tool suitable for many purposes. It should be able to do anything you want it to do: from simple sketches to complex illustrations and technical drawings.

Inkscape is designed to enable users to create complex drawings. It also supports text editing operations like transforming blocks of text into paths and applying other effects.

Considerations When Choosing the CAD/CAM Software

The CAD/CAM software that you choose for your business is a critical decision that will have a major impact on your business. With so many options available, it can be difficult to know which is best for your specific needs. Here are some considerations to think about when choosing CAD/CAM software:

Cost

Cost is one of the most important considerations when choosing CAD/CAM software. The cost of CAD/CAM software ranges from free to several hundred thousand dollars. The price will depend on a number of factors, including the type of software and features that it offers.

Free CAD/CAM Software-If you are strapped for cash and have only minor needs, then free CAD/CAM software might be an option for you. However, free CAD/CAM software is typically limited in its capabilities and has many limitations that make it difficult to use for anything other than simple designs.

Low-Cost CAD/CAM Software-For those who need more advanced features, low-cost CAD/CAM software is available for under $100 per month. This type of software typically has all the basic tools that are needed to create relatively simple designs without any restrictions on usage or output size.

High-End CAD/CAM Software-High-end CAD/CAM software can cost hundreds of thousands of dollars per year but provides extensive capabilities such as 3D toolpath simulation and support for multiple operating systems (OS). This type of software is typically used by companies that have large manufacturing operations where multiple machines need to produce parts at high volumes as quickly as possible with little-to-no downtime.

CNC Techniques Supported

CNC is short for “computer numerical control.” It refers to a group of computer-controlled machine tools that are used in manufacturing. The most popular CNC machines include milling machines, lathes, and saws. These machines use digital data to perform certain tasks, such as cutting through metal or wood.

If you plan on using your CAD/CAM software for CNC purposes, then make sure it supports that type of equipment. You may also want to consider whether the software supports multi-axis devices, which allow users to cut shapes with multiple axes at once. Many CAM programs support just one axis at a time, while others support up to four axes simultaneously.

Rich Features

The feature set offered by different systems varies greatly. For example, some programs offer only basic machining capabilities, while others offer several different types of machining operations. Some programs can also be used for both design and manufacturing purposes, but many are designed exclusively for one or the other activity.

File Formats Supported

If you want to use your CAD/CAM software with other systems and applications, you need to consider the file formats it supports. Typically, CAD/CAM software supports DWG files, although some support other formats as well. For example, SolidWorks supports STEP, IGES, and SAT files, while AutoCAD supports DXF. SolidWorks also supports JPG and PNG images, while AutoCAD allows you to import BMP files.

Some CAD/CAM software also allows you to export your drawings in different formats, such as PDFs or DWGs.

Collaboration with Other Software

One of the first things you’ll need to do when choosing a CAD/CAM solution determines if it will integrate with other software packages in your organization. For example, if you have some employees who use SolidWorks and others who use Autodesk Inventor, it’s critical that your CAD/CAM software can interact with both products seamlessly. If you don’t find this type of integration in your current CAD/CAM solution, then you may want to look at other options before making a final decision.

Open-Source vs. Commercial Software

You’ll also want to consider whether you’d like an open-source or commercial software solution when choosing your CAD/CAM program. Open-source programs are typically less expensive than their commercial counterparts but are less feature-rich and require more hands-on support from the user community. Commercial programs offer more features and support than open-source ones but at a higher cost per seat.

Contact ETCN for custom-quality prototypes and parts

ETCN is a full-service provider of precision machining and fabrication services. With over 25 years of experience in the industry, we take great pride in our ability to provide complete machining solutions for all of your needs.

Need quality cnc machining service in China

As a full-service precision machining house, ETCN has been offering CNC machining to customers with precision machining and high quality service.