What is cnc machining and what are its applications

CNC machining is a process that uses computer numerical control to produce parts and tools from metal, plastic, and wood. CNC machines are typically used in industries such as manufacturing, aerospace, and automotive.

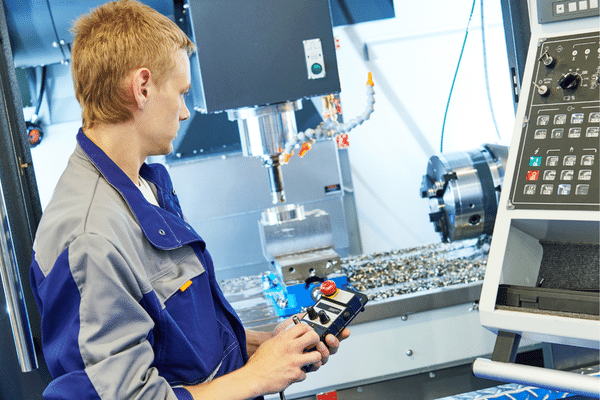

The process involves cutting materials by moving a cutting tool along the surface of the material being machined. In traditional machining processes, operators manually control the motions of the machine tools that are being used to create the final product. In contrast, CNC machines allow operators to write programs that can be executed by computers to complete tasks without requiring human intervention.

CNC machines have many applications in various industries because they can be programmed to perform complex tasks quickly and accurately while using less energy than other types of machines. For example, they can be used for creating prototypes or making high-quality parts with minimal waste material left over after production occurs (which reduces costs). They can also be used for mass production lines since they can produce large numbers of identical parts quickly without requiring any manual intervention from workers who are responsible for operating them properly at all times throughout production cycles! The use of CNC machines in manufacturing has been growing steadily over the past few years. In fact, the U.S. Bureau of Labor Statistics predicts that employment opportunities for machinists will increase by 15% between 2016 and 2026 due to an increasing need for this type of work in various industries!

In essence, a CNC machine is a computer-controlled tool that can be programmed to perform complex operations on any type of material. They are used in many different industries because they can be customized for the specific needs of each one and can produce high-quality products at low costs.

The different types of cnc machines

CNC machining (Computer Numerical Control) is a manufacturing process that is used to create parts and products. CNC machines are typically used to produce large quantities of parts and products, but they can also be used for small-scale production. There are different types of CNC machines, each of which has its own characteristics and uses.

The most common type of CNC machine is the router. A router is typically used to cut materials with a fast-moving tool such as a drill bit or milling cutter. The router’s tool moves along a programmed path while cutting into the material it’s working on.

A milling machine works similarly to a router, except that it uses rotating tools instead of cutting tools. These tools can include drill bits or milling cutters that rotate at high speeds in order to cut into the material being worked on by the machine. They also use circular paths in order to control where their tools go as they work on whatever material they’re cutting through at any given time.

A wire EDM machine uses electrical discharge machining (EDM) technology to create precise shapes in metal alloys by removing extremely thin layers from them using electrical currents instead of mechanical forces like those found in traditional machining processes like turning or mill ing.

A EDM machine uses a sharp electrode to make the cuts, which is moved by the machine along a path in order to create specific shapes with the material being worked on. The process starts with an electrical current being passed through a wire or other type of electrode that has been coated with a substance known as an “abrasive.”

The abrasive is used to remove material from the surface being worked on, and this process creates narrow channels in the metal that are known as “electrical paths.” As these paths are created, the electrode is moved along a pre-determined path by the machine in order to cut away at the material being worked on.

How to choose the right cnc machine for your needs

1.1. Determine your budget.

The first step in choosing the right CNC machine for your needs is to figure out how much you’re willing to spend on it. While there are low-cost machines available, these are often only suitable for hobbyists and casual users who don’t need a lot of power or precision. If you plan on doing more than just playing around with the machine, it’s worth considering investing in something more robust—but don’t go overboard! The last thing you want is to buy something that’s too expensive but doesn’t have the power or features you actually need.

1.2. Think about what kind of work you’ll be doing with the machine.

CNC machines can be used for a wide range of purposes—from simple cutting operations like engraving and milling to more complex functions like drilling holes at precise angles or polishing surfaces with diamond grits—and each type of work requires a different set of specifications and capabilities from your machine’s controller system (we’ll talk about this more later). You should consider not only what types of materials you’ll be using but also what kinds of things those materials will be used for: if all you want is a simple engravement tool , you don’t need to spend as much on a machine as you would if you were planning on using it for more advanced operations like drilling or milling. You should also consider the amount of money that’s available to spend—some machines are very expensive and will require a large initial investment; others can be purchased for less than $1000, which makes them much more appealing for hobbyists who just want something simple.

If you’re looking for a cheap engraving machine, you should consider buying used equipment. A good number of shops sell used machinery, and they can be found online; if you’re not sure where to look, just type “used” and the word “engraver” into your favorite search engine. You may also want to consider purchasing an older model of a new brand of engraver—many companies that make these tools continue making them year after year with only minor changes in design; this means that older models are still good quality but won’t cost as much money because they aren’t considered as modern!

The benefits of using a cnc machine

CNC machining is a type of computer-controlled machining that uses computers to control the machines that are used to create parts. The CNC machine is controlled by a computer program, typically created in CAD software. These programs are used to tell the machine how to move and perform tasks, such as drilling holes or milling edges.

CNC machines are often used for more complex operations than those performed by manual machines. They can be used to make parts that require very precise measurements—such as those used in aerospace and automotive industries—or they can be used for mass-producing parts with similar specifications.

CNC machines have several benefits over manual machines:

They’re faster: With a CNC machine, you can cut down on production time by eliminating human error from your process. Manual machining requires human intervention at every step of production; with a CNC machine, it’s possible for one person (or even an entire team) to manage multiple processes at once and make changes quickly if necessary. This makes it easy to keep up with high demands for custom products or large-scale manufacturing runs without sacrificing quality or consistency across batches or models of product.

They’re safer: Manual machines require someone on site at all times while they’re being used– which can be a safety hazard. CNC machines, however, are designed to stop immediately if something goes wrong with the process or there’s an error in the program. This means that you won’t have to worry about someone getting injured on your production floor if something goes wrong with their machine–and it also means that you won’t have to pay as much for workers’ compensation insurance or other related costs associated with workplace accidents.

They’re more efficient: CNC machines can run 24 hours a day, seven days a week. Manual machines have to be set up and taken down by workers every time they’re used–which means that there’s downtime between batches of production and you’ll need to pay for it.

How to get started with cnc machining

CNC machining is a process that takes place in the manufacturing world. It is used to create precise and detailed products. This article will cover the steps you need to take in order to get started with CNC machining.

Step 1: Understand what CNC Machining is

CNC stands for Computer Numerical Control, which means that it is controlled by computers. In this process, a computer controls the movement of the machine’s cutting tool in order to create a product. The machine can make precise cuts without any human intervention.

Step 2: Learn about the different types of CNC Machining Equipment

There are two main types of equipment that you will need when getting started with CNC machining: numerical control (NC) machines and computer numerical control (CNC) machines. NC machines have been around since before computers were invented while CNC machines have been around since computers were invented; thus they have evolved much more than NC machines over time.

Step 3: Find out how much each type costs

The costs vary depending on what type of machine you buy as well as where you buy it from! Make sure that if you’re buying online then there are no hidden fees involved such as shipping charges or taxes imposed by your state government! Step 4: Learn how to use the machine Once you have purchased your CNC or NC machine, make sure that there is a place where you can take classes on how to use it! You should also have someone show you how to properly set up the program for your machine so that it works as intended.

Step 5: Find a design You will need to find a design for your CNC or NC machine that you can use. You can do this by searching online for “CAD models” or “CAM programs”. There are many websites where you can find these types of files including Autodesk 123D where you can download CAD files for free!